|

Thread Number: 81177

/ Tag: Vintage Automatic Washers

1974 Lady Kenmore Dryer Rebuild |

[Down to Last] |

Post# 1051893 11/22/2019 at 00:50 (1,616 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

With plenty to work on I decided to tackle the Ď74 Lady K dryer today. All the parts arrived and these should be pretty straight forward. The dryer was pretty noisy initially but otherwise seemed to work just fine. Goal is to give it a good cleaning, replace the rollers, belt and lubricate everything. We will throw in a new felt drum seal and replace seals around the filter and exhaust connections.

Here we go! Always unplug first! New light bulb since this one ainít workin.

View Full Size

| ||

|

Post# 1051894 , Reply# 1 11/22/2019 at 00:51 (1,616 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

Next

Pop the top and remove the kick panel and front panels. We need to get up in there and get the drum and old belt out. Then we can do some serious cleaning and get those old rollers out.

| ||

Post# 1051895 , Reply# 2 11/22/2019 at 00:58 (1,616 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

Drum is out

Big drum out and now we can clean up and put in new rollers.

| ||

Post# 1051896 , Reply# 3 11/22/2019 at 01:02 (1,616 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

Rear panel

Time to remove the rear panel and clean more. Will remove the fan and wash it, clean around it and replace. Per Jason, remove the lint filter warning light hoses and blow air into them to ensure they are clean. The large filter manifold is easily removed for cleaning and new gaskets placed to seal off and prevent lint build up inside the dryer.

| ||

Post# 1051897 , Reply# 4 11/22/2019 at 01:03 (1,616 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

Since we are back there...

Letís install a new power cord.

View Full Size

| ||

Post# 1051898 , Reply# 5 11/22/2019 at 01:04 (1,616 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

Felt drum seal

Tear off the old felt rear drum seal and replace with a new one. Good news about these dryers is they are all the same! Plenty of available parts!

View Full Size

| ||

Post# 1051899 , Reply# 6 11/22/2019 at 01:06 (1,616 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

Lubricate the motor

Jason suggested drilling a couple of small holes in the motor housing and adding lubricant. Whatever she says I do!

View Full Size

| ||

Post# 1051900 , Reply# 7 11/22/2019 at 01:08 (1,616 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

Letís get her all back together

New idler pulley wheel and a new belt. Get her all out together! The door hinges were pretty noisy so a little 3-in-1 oil takes care of that.

| ||

Post# 1051901 , Reply# 8 11/22/2019 at 01:09 (1,616 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

And weíre done!

Sheís all back together and ready to be the best dryer Iíve ever owned!

View Full Size

| ||

Post# 1051906 , Reply# 9 11/22/2019 at 04:53 (1,615 days old) by appnut  (TX) (TX) |

||

|

| ||

Post# 1051907 , Reply# 10 11/22/2019 at 05:08 (1,615 days old) by Ultramatic  (New York City) (New York City) |

||

| ||

Post# 1051908 , Reply# 11 11/22/2019 at 06:59 (1,615 days old) by turquoisedude  (.) (.) |

||

| ||

Post# 1051929 , Reply# 12 11/22/2019 at 10:11 (1,615 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

Easy to service

Glad you all are enjoying the photos! This dryer is actually pretty easy to get into and work on. Honestly, the hardest part was probably changing the light bulb because itís a narrow 26Ē bulb in a very tight space.

Having worked on and rebuilt three GE dryers, this is my first Kenmore to dive into. The quality of this machine is remarkable to say the least. The panel alone probably weighs 15-20 lbs. all of the sheet metal is thick and it is very well-designed and built. Donít get me wrong. The GEs are good performers but Kenmore definitely had quality on their side. Iím curious about one thing and maybe you all know the answer to this. Notice in the first photo with the panel open the green circuit panel. Was this the first Solid State model Kenmore or were they using circuit boards prior? | ||

Post# 1051937 , Reply# 13 11/22/2019 at 11:18 (1,615 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

2 things | ||

Post# 1051943 , Reply# 14 11/22/2019 at 12:26 (1,615 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

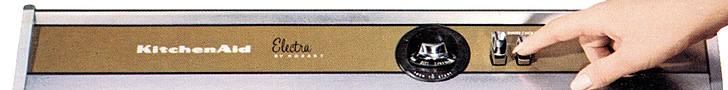

And we have lift-off!

Hooked up this morning and running nice and smooth. Here are some close-up finish photos. The options are actually pretty minimal since you can basically choose a dryness level and a temp. It pretty much is on autopilot after that. End of cycle signal is a variable loudness setting and wrinkle guard is either on or off. Two warning lamps are for the lint trap and another alerting g that the cycle is almost finished. I dunno but I think the wood grain might grow on me.

| ||

Post# 1051944 , Reply# 15 11/22/2019 at 12:56 (1,615 days old) by DADoES  (TX,†U.S. of A.) (TX,†U.S. of A.) |

||

|

| ||

Post# 1051948 , Reply# 16 11/22/2019 at 13:18 (1,615 days old) by bradfordwhite  (central U.S.) (central U.S.) |

||

You make it look easy and fun. Fixing driers typically is because it's a matter of cleaning and changing out simple parts. The washers.... not so easy. plumbing can't leak. several parts are dependent on others to work or you have to take so many parts off to get to a part. There's more to it, that's for sure. Still it's better than a refrigerator, freezer, or A/C units sealed system which I can't even do. Dangerous flammable chemicals, expensive tools. Precision measurements. One has to have their limits. | ||

Post# 1051949 , Reply# 17 11/22/2019 at 13:19 (1,615 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

Dadoes | ||

| Post# 1052010 , Reply# 18 11/22/2019 at 23:15 (1,615 days old) by hippiedoll ( arizona ) | ||

WOWZERS!! | ||

Post# 1052061 , Reply# 19 11/23/2019 at 08:41 (1,614 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 1052066 , Reply# 20 11/23/2019 at 09:19 (1,614 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

1974 LKM Dryer I rebuilt and have used the gas version of this dryer for over 30 years at our house as our primary dryer, it has never disappointed me. It drys fast and consistently I have never had to set the dryness level above 4%.

Some interesting things about the control system, this is probably the first really Smart-Dryer, If the dryer does not sense dry clothing after 110 minutes it will shut down, so it will not run all day and night if there is some sort of failure.

It also has a proportional cool-down time, passed on how long the control takes to register the selected dryness level will determine long long the dryer will operate with the heat off for cool-down, the CD will vary from 3-10 minutes. This again makes sure the dryer will shut off consistently even if it installed in a 120F boiler room. Earlier EC dryers relied on a CD thermostat and would either shut off too soon or never shut off in very warm areas.

All fully ECed dryers have these safety's designed into them today, WP got these features on their TOL dryers with the 1977 LFE-I9800 dryers.

John L. | ||

Post# 1052073 , Reply# 21 11/23/2019 at 10:21 (1,614 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

I swear John  | ||

| Post# 1052074 , Reply# 22 11/23/2019 at 10:36 (1,614 days old) by eurekastar (Amarillo, Texas) | ||

|

| ||

| Post# 1052139 , Reply# 23 11/24/2019 at 10:50 (1,613 days old) by cornutt (Huntsville, AL USA) | ||

|

Very cool Could you take a photo of the component side of the circuit board? I'm curious to see what parts are on it. | ||

Post# 1193362 , Reply# 24 11/10/2023 at 21:46 by marky_mark  (From Liverpool. Now living in Palm Springs and Dublin) (From Liverpool. Now living in Palm Springs and Dublin) |

||

Thanks so much for doing this thread, Jon! It's been great to read.

I am trying to remove the lint filter manifold but I don't see how I can get it out. The rear cabinet of this machine goes lower than on modern WP dryers, so I can't see how the manifold can be removed with the rear cabinet still in place. What am I missing? Hope someone can let me know!

View Full Size

| ||

Post# 1193363 , Reply# 25 11/10/2023 at 22:22 by DADoES  (TX,†U.S. of A.) (TX,†U.S. of A.) |

||

|

| ||

Post# 1193364 , Reply# 26 11/10/2023 at 22:47 by marky_mark  (From Liverpool. Now living in Palm Springs and Dublin) (From Liverpool. Now living in Palm Springs and Dublin) |

||

We have success! Hi Glenn. Yes I had removed those screws but couldn't manoeuvre it out.

So what I have just done is remove the bolts from the rear bulkhead. This allowed me to push the bulkhead forward a little to allow more room to remove it. I did indeed remove it up and out via the top rather than removing it down and out at the rear. I'm sure there's probably a much easier way of doing it, but this was all I could think of!

View Full Size

| ||

Post# 1193368 , Reply# 27 11/11/2023 at 04:36 by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

19 74Ė75 Lady Kenmore dryer

Good morning Mark this is actually the correct way to get the lit filter housing out of the dryer about the only reason this ever Hass to come out is to replace the blower wheel and itís not that hard once you get used to it.

We also occasionally have to remove one in the field if somebody spills a bottle of liquid detergent down the lint filter, duct or something awful like that happens . Even though you found a lot of Lint inside the blower housing and Iím sure itís a good idea to clean it out. It does not affect dryer performance. They almost never get clogged enough that this is a necessary repair operation. John | ||

Post# 1193439 , Reply# 28 11/11/2023 at 22:19 by marky_mark  (From Liverpool. Now living in Palm Springs and Dublin) (From Liverpool. Now living in Palm Springs and Dublin) |

||

Hi John. Thanks for the reply. I removed the ductwork in order to replace the seals on the blower and the lint trap housings.

I wouldn't have bothered taking it apart just to clean out lint from the ductwork. As you say, you only find a very small accumulation of lint within the ductwork and blower, probably equivalent to about one to two cycles' worth of lint. What I do always find is a small collection of toothpicks, plastic collar stays and the odd safety pin. I was not fortunate enough on this occasion to find any money though!

Dryer is all back up and running now. Thank you! Mark

| ||

Comes to the Rescue!

Comes to the Rescue!