|

Thread Number: 91532

/ Tag: Vintage Automatic Washers

Whirlpool transmission noises |

[Down to Last] |

| Post# 1160511 9/27/2022 at 16:46 (570 days old) by Maytag85 (Sean A806) | ||

Hereís a issue that my 1963 RCA Whirlpool Imperial Mark XII has developed in the past 2 months or so. It goes through all the cycles like itís supposed to but makes a peculiar clunk-clunk-clunk/knock-knock-knock noise when agitating but doesnít do it when in the neutral drain. Kind of stumped since I rebuilt it in the spring of 2021 which means it only has a total of 16 months of use on it. Have another Whirlpool transmission that made the same clunk-clunk-clunk/knock-knock-knock when agitating as well but looked closely at the gears the other day and there doesnít appear to be an excessive amount of wear on them which has me stumped as well. Has anyone else had this happen to a Whirlpool or Kenmore belt drive washer before or not? Just a little stumped since I didnít rebuild the transmission that long ago.

| ||

|

| Post# 1160537 , Reply# 1 9/27/2022 at 22:50 (569 days old) by Maytag85 (Sean A806) | ||

This is the sound the original and used Whirlpool transmissions make while agitating. In neutral drain it sounds like itís supposed to but when agitating it makes that clunking/knocking noise.

CLICK HERE TO GO TO Maytag85's LINK | ||

| Post# 1160539 , Reply# 2 9/27/2022 at 23:21 (569 days old) by Repairguy (Danbury, Texas) | ||

| ||

| Post# 1160540 , Reply# 3 9/27/2022 at 23:24 (569 days old) by Maytag85 (Sean A806) | ||

Reply #2 | ||

Post# 1160562 , Reply# 4 9/28/2022 at 11:27 (569 days old) by ryner1988  (Indianapolis) (Indianapolis) |

||

| ||

Post# 1160573 , Reply# 5 9/28/2022 at 14:17 (569 days old) by bradfordwhite  (central U.S.) (central U.S.) |

||

#1 | ||

| Post# 1160579 , Reply# 6 9/28/2022 at 15:44 (569 days old) by vacerator (Macomb, Michigan) | ||

|

Sean, is it noisy in spin? Is the clunking only under load, or even agitating without water? Check the wig wag bolts. Check the agitator bolt down. Check the spin tube bearings for play. If they are ok, the trans crank rod may have play inside on the gears. | ||

| Post# 1160607 , Reply# 7 9/28/2022 at 22:34 (568 days old) by Maytag85 (Sean A806) | ||

Reply #6

The spin is a bit noisy since the bearings are worn and do have a new set of bearings for it but will simply use it till it gives up the ghost and will install the new bearings and spin tube on it. I donít think worn bearings would cause the transmission to make noise while in operation, even with worn/tired bearings, a Whirlpool belt drive washer still should be when agitating. I checked the agitator bolt, wig wag, mounting bolts/braces, and anything I could think of and still is making noise while agitating. I throughly checked everything when I installed the rebuilt transmission in the spring of 2021, same thing with the used/spare Whirlpool transmission I have. Thereís a little play in the connecting rod on the spare Whirlpool transmission but isnít excessive to cause it to make a clunking sound when agitating but for experimenting purposes, I might pack that one with corn head grease and if that solves the problem, thatís what Iíll do to the original transmission the machine came with. Corn head grease should definitely work since it turns into a heavy gear oil when mixed around in a gear case but turns back into a grease once it settles.

| ||

| Post# 1160611 , Reply# 8 9/28/2022 at 23:19 (568 days old) by Repairguy (Danbury, Texas) | ||

I donít believe that is a gearcase problem. When I looked the first time I thought the motor the motor was moving independent of the baseplate which led me to believe the mounts were loose but after watching again the movement is with the baseplate so thatís not it. The noise is rhythmic with the movement of the baseplate. Was there a load of clothes in the machine in this video? Watch and listen closely and the sound coincides with the baseplate moving back and forth. Was the baseplate ever removed? Are all of the suspension mounts tight?

| ||

| Post# 1160614 , Reply# 10 9/29/2022 at 00:21 (568 days old) by Repairguy (Danbury, Texas) | ||

| ||

| Post# 1160615 , Reply# 11 9/29/2022 at 00:22 (568 days old) by Maytag85 (Sean A806) | ||

Reply #8

I actually was waning a load of towels when I made this video last year. I considered removing the baseplate but didnít since there was limited room inside the garage at the time and just left it inside the cabinet. The only suspension mound I loosened was the very front one near the automatic dispensers since I had to loosen it to remove and install the automatic dispensers since I took it out for a cleaning before I put the machine back together last year. I tightened everything when I put it back together but will look into it this weekend and double check and tighten and loose bolts or set screws that have worked loose.

Reply #9 Maybe the eccentric on the main drive gear might be out of adjustment since service manual seems to describe the problem I am having but will check all the mounting bolts and set screws to be sure. | ||

Post# 1160627 , Reply# 12 9/29/2022 at 03:23 (568 days old) by Adam-aussie-vac  (Canberra ACT) (Canberra ACT) |

||

|

Reply 10 What does that particular adjustment do? Does it control the stroke length? | ||

Post# 1160628 , Reply# 13 9/29/2022 at 03:45 (568 days old) by bradfordwhite  (central U.S.) (central U.S.) |

||

| ||

| Post# 1160632 , Reply# 14 9/29/2022 at 06:47 (568 days old) by vacerator (Macomb, Michigan) | ||

|

Is it possible, like with an eng ine, that nosies can echo, and not be where they sound like the are? Especially with such a large base plate, and all steel tub? | ||

Post# 1160635 , Reply# 15 9/29/2022 at 07:39 (568 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Clunking noise whirlpool belt drive transmission Hi Sean, you just have to figure out where the noise is coming from have you used to stethoscope on the transmission to see if it seems to be coming out of the gear case?

Try putting a heavier load in the washer and see if the clunking noise increases that makes it more likely that it is a transmission problem.

The transmission you have in this washer is too new to have an a eccentric adjustment on it, so if the transmission is worn you can only replace parts internally.

When you serviced this transmission what was wrong with it ? did it have water in it before you redid it, if so it may be badly worn.

The clunk in a transmission like this is either a warn connecting rod which the eccentric adjustment will correct or the gear that engages on the agitator shaft pin either the pin or the gear could be worn.

John L. | ||

| Post# 1160641 , Reply# 16 9/29/2022 at 10:41 (568 days old) by Maytag85 (Sean A806) | ||

Reply #15

When I took apart the used/spare Whirlpool transmission, the oil was a milky brown color which is signs of water contamination. Since thereís a date code of 77 for 1977 on one of the gears inside the used Whirlpool transmission, my assumption is it was involved in a basement flood or something and wasnít from the center post seals leaking since all belt drive washers in 1977 still had the full height center post vs the 1978 and later belt drive washers that had the half height center post which would leak once the seals would let go.

Since I looked at the gears closely, thereís some wear on the gears but not a excessive amount but some wear nevertheless on them. Not sure if you are supposed to do this but might just pack the used Whirlpool transmission (the one in the video) with some corn head grease for experimentation purposes since corn head grease turns into a heavy gear oil when mixed around but returns back to a normal grease once it sits. Definitely should help quiet it down some since corn head grease is heavier than gear oil. | ||

Post# 1160661 , Reply# 17 9/29/2022 at 21:08 (567 days old) by bigalsf  (Salt Lake City) (Salt Lake City) |

||

|

Sorry Sean, I did not watch the video closely enough. My bad! :) What happened to the original transmission? | ||

| Post# 1160664 , Reply# 18 9/29/2022 at 22:02 (567 days old) by Maytag85 (Sean A806) | ||

Reply #17

Long story short, I began the tear down of the machine in December of 2020 since I tried to remove the hose that goes from the automatic dispensers to the ďTĒ on the side of the tub but that ended up snapping off.

Ended up having to remove the inner tub which then found out there was some rust at the bottom of the tub and at that point Iíd figure I would just do a rebuild (at least a partial rebuild of the machine) and wouldnít make sense to not go through certain things while the machine was apart. In the process of trying to remove the metal drive block from the original agitator shaft, the original agitator shaft on the transmission ended up getting damaged since it wasnít wanting come come off without a fight and just took a hacksaw to it and to avail it came off. Since the agitator shaft ended up getting damaged, I couldnít use the transmission until I went through it so I just set it aside in the shed until spring arrived. I ended up buying a used Whirlpool transmission off of eBay for $45 (thatís the transmission in the video) but didnít like the clunking sounds it made when in operation and made it a priority to rebuild it in the spring time. Since it rained quite a bit in the spring of 2021 and the shed roof leaked, water did make itís way into the original transmission but since it wasnít in use and just sitting, the water and oil didnít have a chance to mix contaminating the oil and causing corrosion inside the transmission. I cleaned up the original transmission, ordered a new agitator shaft since Swestoyz sent me the link in messenger (thanks Ben!), put the new agitator shaft and spring in, topped it off with 90 weight gear oil, installed it into the machine and put it into service that following summer. Not much went on with the machine from June to September but in October, thatís when I had issues with the tub leaking. Patched the pin holes in the outer tub with JB Weld Steel Stik and that worked for a little while but started leaking again in December. Ended up taking the outer tub to my sisterís boyfriendís uncle who was kind enough to weld up the pin holes in the tub and so far those repairs to the outer tub have held up. Not much went went on after that until someone in April when another leak appeared and just set it aside and put my Maytags back in service, turns out the tub ring seal wasnít aligned causing some water to slosh over and spill onto the floor but got thar issue corrected. Not much happened after the issue with the tub ring seal until the transmission started clunking and knocking about 3 or 4 weeks ago. Currently going through the used Whirlpool transmission and going to pack that with corn head grease for experimentation purposes and to see how well it works inside of a Whirlpool transmission and if itís successful, thatís what Iíll recommend for anyone whoís rebuilding a Whirlpool/Kenmore belt drive transmission and if not, then I wonít recommend/suggest anyone to pack a belt drive transmission with corn head grease but you live and you learn. Thatís basically the timeline of things Iíve done and have popped up since Iíve owned my Whirlpool for 2 years. Just gradually fixing it up and restoring it as time goes on and have some more stuff that I plan on doing in the future to it but just taking one step at a time with it until everything is fixed on it. | ||

Post# 1160667 , Reply# 19 9/29/2022 at 22:18 (567 days old) by bigalsf  (Salt Lake City) (Salt Lake City) |

||

|

So the original transmission is installed now? What is the transmission in the video? | ||

| Post# 1160675 , Reply# 20 9/29/2022 at 22:58 (567 days old) by Maytag85 (Sean A806) | ||

Reply #19

The original transmission is back in the machine (making the same noises as the used Whirlpool transmission) and the used Whirlpool transmission is on the bench since I am in the process of cleaning it up and going to out it back together in October and will put that one back in since itíll be packed with corn head grease then Iíll remove the original transmission and will do another tear down along with along with a diagnosis to see why itís clunking and knocking in operation.

| ||

| Post# 1160688 , Reply# 21 9/30/2022 at 00:38 (567 days old) by Maytag85 (Sean A806) | ||

Figured out the problem

I believe I figured out what the problem was, added some more gear oil to the transmission and seems to have quieted it down back to normal but will see when I go to wash a large load of towels since I am currently washing a medium load of dusting cloths and such and so far seems to be running smoothly.

| ||

| Post# 1160689 , Reply# 22 9/30/2022 at 00:47 (567 days old) by Maytag85 (Sean A806) | ||

Never mind

The sound has returned. One thing I just did was I put my had on the agitator cap while it was agitating, I can feel the sound travel up the agitator shaft which leads me to believe itís either the agitator fork, agitator fork spring, or the agitator gear that drops down and engages the agitator shaft.

| ||

| Post# 1160690 , Reply# 23 9/30/2022 at 02:21 (567 days old) by Maytag85 (Sean A806) | ||

Never mind x2 | ||

| Post# 1160696 , Reply# 24 9/30/2022 at 07:00 (567 days old) by vacerator (Macomb, Michigan) | ||

|

Good Sean! More often than not, it's something simple, like when a car won't crank, it's usually the battery, or a loose or dirty cable terminal. | ||

Post# 1160741 , Reply# 25 9/30/2022 at 20:13 (566 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Clunking noise from a whirlpool belt drive washer | ||

| Post# 1160798 , Reply# 26 10/1/2022 at 10:32 (566 days old) by Maytag85 (Sean A806) | ||

Reply #25

I replaced the main transmission drive pulley back in the spring of 2021 when I rebuilt the transmission. I have another transmission pulley but itís for the quiet pack Whirlpool and Kenmore belt drives with the thin belt and I might put that pulley on the Whirlpool transmission I am going to rebuild this month (the one in the video) and will try to locate a thin belt for it. I think my local hardware store should have a belt that will fit it since they had all kinds of v-belts while I was there awhile back. Definitely will make the machine nearly silent in operation with the thin belt along with the newer style of wig wag on it.

| ||

Post# 1160800 , Reply# 27 10/1/2022 at 11:01 (566 days old) by DADoES  (TX,†U.S. of A.) (TX,†U.S. of A.) |

||

|

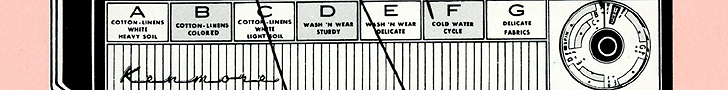

Quiet-Pak

†

Full-meal-deal Quiet-Pak has different grommets for mounting the motor to its brackets, different brackets to accommodate the grommets, and all the pulleys must accommodate the thin belt ... pump, transmission, basket drive, and motor (the motor pulley has a rubber bushing).

View Full Size

| ||

Post# 1160868 , Reply# 28 10/1/2022 at 22:45 (565 days old) by jons1077  (Vancouver, Washington, USA) (Vancouver, Washington, USA) |

||

Transmission noises | ||

| Post# 1160869 , Reply# 29 10/1/2022 at 22:52 (565 days old) by Maytag85 (Sean A806) | ||

Reply #28

What I plan on doing to the spare Whirlpool transmission I have is packing it with corn head grease since corn head grease turns into a heavy gear oil when mixed around in a gear case but returns back into a grease once it settles and definitely will work in a belt drive transmission with worn/comprised seals.

| ||

Comes to the Rescue!

Comes to the Rescue!