|

Thread Number: 23873

Primus w-10X^2 update |

[Down to Last] |

|

| Post# 371626 , Reply# 1 8/12/2009 at 20:34 (5,370 days old) by supremewhirlpol () | ||

|

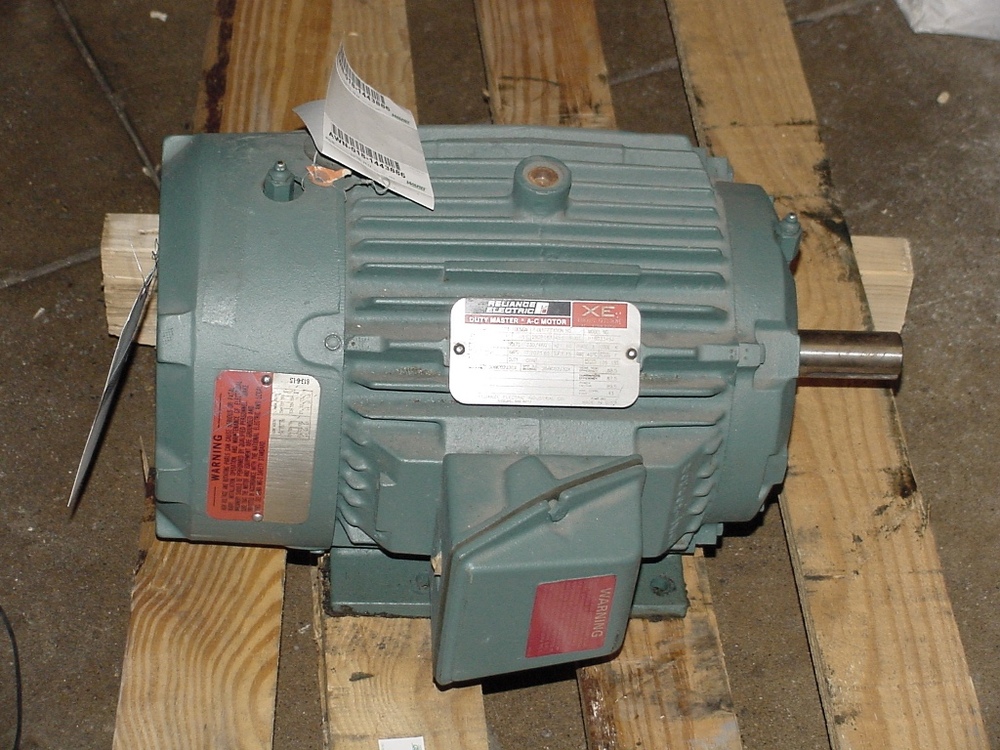

close-up of the motor

| ||

| Post# 371627 , Reply# 2 8/12/2009 at 20:35 (5,370 days old) by supremewhirlpol () | ||

|

What do you guys and gals think? | ||

Post# 371646 , Reply# 3 8/12/2009 at 21:30 (5,370 days old) by frigilux  (The Minnesota Prairie) (The Minnesota Prairie) |

||

| ||

Post# 371659 , Reply# 4 8/12/2009 at 22:55 (5,370 days old) by volvoguy87  (Cincinnati, OH) (Cincinnati, OH) |

||

Great Scott!!! | ||

| Post# 371745 , Reply# 5 8/13/2009 at 09:46 (5,370 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622

Wow that is a motor, compared to my commuter motor, sort of makes it look small. Iím currently working on a proper printed circuit board complete with new chip (PIC 16F77), with new programs and hopefully a time line to show progress of the wash cycle. Need to build a light box to photo develop circuit design onto copper clad board, I tried some iron on transfer sheets but have been unsuccessful. Also milling over a jog switch instead of push switches. If I can get the developing to working I will make one of each board which can be inter changed.

| ||

| Post# 371746 , Reply# 6 8/13/2009 at 09:57 (5,370 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622 | ||

Post# 371969 , Reply# 8 8/14/2009 at 03:11 (5,369 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

wow

Monster washer indeed, Is this the washer in your profile pic?? will the bearings be able to cope with the extra speed & inertia without going into sub orbit?? am looking for an asko shell that I could do that with and put a clear perspex frame around it to observe the inner working etc. Interesting projects guys!! Mike | ||

| Post# 373281 , Reply# 9 8/19/2009 at 19:08 (5,363 days old) by supremewhirlpol () | ||

|

************Update 8-19-09************ I have the pulley... it is 8"(outer diameter) 1 1/8" (inner diameter(shaft)).

| ||

Post# 373353 , Reply# 11 8/19/2009 at 23:59 (5,363 days old) by tolivac  (greenville nc) (greenville nc) |

||

|

There are some motors just like yours here at work-they are spinning blowers for the building HVAC system-3 and 5 hp-3Ph208V. | ||

Post# 373359 , Reply# 12 8/20/2009 at 00:20 (5,363 days old) by volvoguy87  (Cincinnati, OH) (Cincinnati, OH) |

||

Hmmmmm... | ||

| Post# 373435 , Reply# 13 8/20/2009 at 12:40 (5,363 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622 | ||

| Post# 373604 , Reply# 15 8/21/2009 at 12:11 (5,362 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622

Yes I have also had some costing for one-off production of a board; average of £70 so will persevere with making my own. I have 4 designs in my head at the moment and canít decide which one to go with. I will take photos of the stages of production, even my many mistakes which will happen I am sure. | ||

| Post# 373629 , Reply# 16 8/21/2009 at 16:04 (5,362 days old) by supremewhirlpol () | ||

|

hotpoint 95622... Yes, I'd like to see the pictures. Good luck on your board designs. How much time have you dedicated to this project so far? | ||

| Post# 373768 , Reply# 17 8/22/2009 at 09:16 (5,361 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622 | ||

| Post# 373769 , Reply# 18 8/22/2009 at 09:17 (5,361 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622 | ||

| Post# 373770 , Reply# 19 8/22/2009 at 09:18 (5,361 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622 | ||

| Post# 373772 , Reply# 20 8/22/2009 at 09:25 (5,361 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622 | ||

| Post# 373786 , Reply# 21 8/22/2009 at 11:09 (5,361 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622 | ||

| Post# 373788 , Reply# 22 8/22/2009 at 11:10 (5,361 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622 | ||

| Post# 373789 , Reply# 23 8/22/2009 at 11:12 (5,361 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622 | ||

| Post# 373790 , Reply# 24 8/22/2009 at 11:13 (5,361 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622 | ||

| Post# 373791 , Reply# 25 8/22/2009 at 11:15 (5,361 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622 | ||

| Post# 373792 , Reply# 26 8/22/2009 at 11:19 (5,361 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622 | ||

| Post# 373795 , Reply# 27 8/22/2009 at 11:25 (5,361 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622 | ||

| Post# 373797 , Reply# 28 8/22/2009 at 11:28 (5,361 days old) by hotpoint95622 (Powys) | ||

hotpoint 95622 | ||

Comes to the Rescue!

Comes to the Rescue!