|

Thread Number: 4045

The Super Unimatic Now Talks Back To The Computer |

[Down to Last] |

Post# 94926 11/20/2005 at 22:36 (6,737 days old) by unimatic1140  (Minneapolis) (Minneapolis) |

||

Continuing the story of the ever evolving PC computer controlled washer, the Super Unimatic washer now is talking back to the computer and the computer is listening, YAY this was the biggest hurdle yet. I worked on two things this week, a unbalance sensor and a pump pressure switch, both to my shock work perfectly after a bit of tweaking get them adjusted.  Unbalance Sensor & Switch: The unbalance sensor of course is there to stop the machine from spinning with any unbalanced wash loads. I took a micro switch with an actuating rod and bent the rod so it faces outward (see picture). Then I attached the switch to a copper pipe that I bent so the switch actuating rod would face the motor. I attached the copper pipe and switch to an L-shaped bracket which attaches to the washer cross brace. When the washer is experiencing an out of balance load, the motor will swing and gently tap the rod on the switch. This sends a tiny 4.5volt DC signal to the computer which alerts the computer that the wash load might be unbalanced. I programmed the software not to shut the washer down unless the switch is depressed three times. Sometimes when Unimatics start to spin and begin to throw the water out of the tub the clothing on one side can arrive at the side of the tub faster then the other side and this can sway the wash tub once or twice but then the load balances itself perfectly as speed quickly picks up. Having the computer count the knocks on the switch three times will help prevent ďfalse alarmĒ unbalance loads that can happen with ďtraditionalĒ a Unimatic. Itís working perfectly now and in nine wash loads done today, the sensor only detected one actual unbalance load. When the washer senses an unbalance load, the machine stops and the computer displays:

| ||

|

Post# 94928 , Reply# 1 11/20/2005 at 22:43 (6,737 days old) by unimatic1140  (Minneapolis) (Minneapolis) |

||

Now the pump pressure sensor is even more exciting, I found it a Grainger last week. This sensor ďfeelsĒ the amount of water pressure that is coming out of the recirculation pump and back into the wash tub. When the water level is lowF as when the machine first starts to fill the outer cabinet, the pressure in the pump is very low, but as more and more water enters the recirculation system, the pressure builds in the pump and spray flume, and the spray gets stronger and stronger. When the recirculating water pressure reaches near 100% of its full spray force, the pressure sensor clicks on and sends a message to computer telling the computer to cut the incoming fresh water flow off. This means no more timed fills! So now Iíve change the Four Minutes of Magic Cycle to work like this: 1. The hot water line flush is done and the residual cold water is pumped down the drain 2. All incoming fresh water is stopped and the tub is brought up to full 1140rpm spin throwing the dry detergent into the outer cabinet. 3. After the tub is at full 1140rpm speed, fresh water begins entering the outer tub and the recirculation pump is started. Since the spinning clothes are completely dry, the water pressure coming out of the recirculation pump is low as most of the soapy water being pumped up from the cabinet and being spit onto the spinning dry clothing is being absorbed. As the clothes become more and more saturated with sudsy water, the frothy water starts spinning over the top of the tub and provides more water for the recirculation system, this causes the pressure to build in the spray stream, when the pressure gets very high the pump pressure sensor clicks and tells the computer to shut off the incoming fresh water. Now the fill for 4 Minutes of Magic is no longer a timed fill, but a actual metered fill, using only three or so gallons of water, which keeps the detergent concentration as high as possible for every type of wash load. Once the 4 Minutes of Magic Cycle is over the tub stops and the 3 gallons or so of sudsy water is pumped back up into the wash tub, then the pump pressure switch resets due to falling recirculation pressure and the computer now brings fresh water into the outer tub for the upcoming wash cycle and this fresh waster is spit up into the wash tub by the pump. This continues until the tub is full of water and begins to overflow. Since the tub is now full and overflowing more water is now available for the recirculation pump and a high pressure stream starts again and the pressure sensor tells the computer that the pump is at full pressure, which means the tub is full of water. Now the computer stops the fresh water flow but keeps the recirculation going and starts the agitation for the wash cycle. What this means is now we have the worlds first metered fill Unimatic! Here is the best part, Iíve discovered that during the fill period of the 4 Minutes of Magic there is a great difference in the time it takes to saturate a full spinning wash load of dry towels than it does say with one just two cotton shirts. Iíve programmed the software to temporarily keep in its memory the amount of time it takes to saturate the spinning dry clothes. So for example a large load of towels takes 68 seconds of fill/spin to bring the pump up the full pressure, where two cotton shirts it only takes 24 seconds. Now later on during the wash fill I can use that time to determine how much water is needed for the wash cycle. Obviously the full load of towels gets a full overflowing tub fill of wash water, but the two shirts donít need a full tub of water, for that small load I only need the tub to be filled with 1/3 water. By playing with the software Iíve discovered that if I multiply the saturation time by 2.25, I automatically get the amount of wash water fill time needed for a smaller, less than full tub of water wash loads. So if our two shirts took 24 seconds of soapy spray to fully saturate them, later on in the wash fill, I fill for 54 seconds and I have just enough water to wash those two shirts. Of course with a lower water level, the computer will automatically provide a much shorter wash time. So now the Super Unimatic can automatically figure out itís water level for the wash. Of course any cycle that I want the heater on, the tub has to be full and recirculating, but I would only do two or so heated wash cycles a week, the rest can be have the water level sensed automatically. Building this machine has been great fun to say the least. Next on the list, is a system to measure the rinse fills, plus dispensers and probably a bigger window in the front. | ||

Post# 94938 , Reply# 3 11/20/2005 at 23:12 (6,737 days old) by appnut  (TX) (TX) |

||

|

| ||

Post# 94944 , Reply# 4 11/20/2005 at 23:34 (6,737 days old) by dadoes  (TX,†U.S. of A.) (TX,†U.S. of A.) |

||

|

Yup, that's all sort of an alternate method of what F&P does with their EcoActive wash and automatic water level sensing. Very Kewl! Hey, what about a way to use the recirculation pump and water heating without going through the tub, by diverting the recirculation spray back into the cabinet? Then it could be done with less water and faster heating for a small load. | ||

Post# 94950 , Reply# 5 11/21/2005 at 00:46 (6,737 days old) by sudsmaster  (SF Bay Area, California) (SF Bay Area, California) |

||

| ||

Post# 94958 , Reply# 6 11/21/2005 at 06:03 (6,737 days old) by toggleswitch  (New York City, NY) (New York City, NY) |

||

|

mutl-talented muli-tasker | ||

| Post# 94967 , Reply# 7 11/21/2005 at 07:13 (6,737 days old) by brent-aucoin () | ||

|

This creation of yours is so amazing Robert! Brent | ||

Post# 94983 , Reply# 9 11/21/2005 at 09:02 (6,736 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 94990 , Reply# 10 11/21/2005 at 09:37 (6,736 days old) by unimatic1140  (Minneapolis) (Minneapolis) |

||

Hey, what about a way to use the recirculation pump and water heating without going through the tub, by diverting the recirculation spray back into the cabinet? Then it could be done with less water and faster heating for a small load. Glenn that's not a bad idea actually! Although the purpose of the heater is just to keep the water hot, as our household water heater provides the hot water to begin with. But I suppose I could wash for a bit, spin the water out into the cabinet and heat it for a few minutes, then pump it back up into the wash tub. Ohhh more food for thought, thanks Glenn! You really do have to beat Glenn's IWL12 with this one Well I've got it beat by 140rpm :) But what does the F&P washer do that is similar to this??? Chris that idea of having four our five quick metered fills in the outer tub and pumped up into the inner tub is actually quite brilliant!!!! I might have to think about that one for a while and possibly incorporate it for small loads in the SU. Hmmmm, more food for thought. Actually Iím thinking now. If I have a pressure switch that measures two gallons of water in the outer tub, I can use the "dry clothes saturation time" to determine how many of those two gallon pump ups I need! That way no matter if the house water pressure is changes between the 4 Minutes of Magic and the Wash Fill, I still will get the exact amount of water necessary! The recirculation pump pushes 15 or so gallons of water a minute, so it could push two gallons up in about 10 seconds so it wouldnít add much more time to the cycle. That is Just Brilliant YAY, this input is just great, together we will build the coolest washer ever. Ben do you recognize that Pump Pressure Switch? Tell me, does the SU come equipped with a Neal-lock? Yup, itís the first password protected Unimatic Washer! | ||

Post# 95002 , Reply# 11 11/21/2005 at 10:32 (6,736 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

| ||

Post# 95021 , Reply# 13 11/21/2005 at 13:15 (6,736 days old) by foraloysius  (Leeuwarden, Friesland, the Netherlands) (Leeuwarden, Friesland, the Netherlands) |

||

| ||

Post# 95092 , Reply# 14 11/21/2005 at 22:48 (6,736 days old) by unimatic1140  (Minneapolis) (Minneapolis) |

||

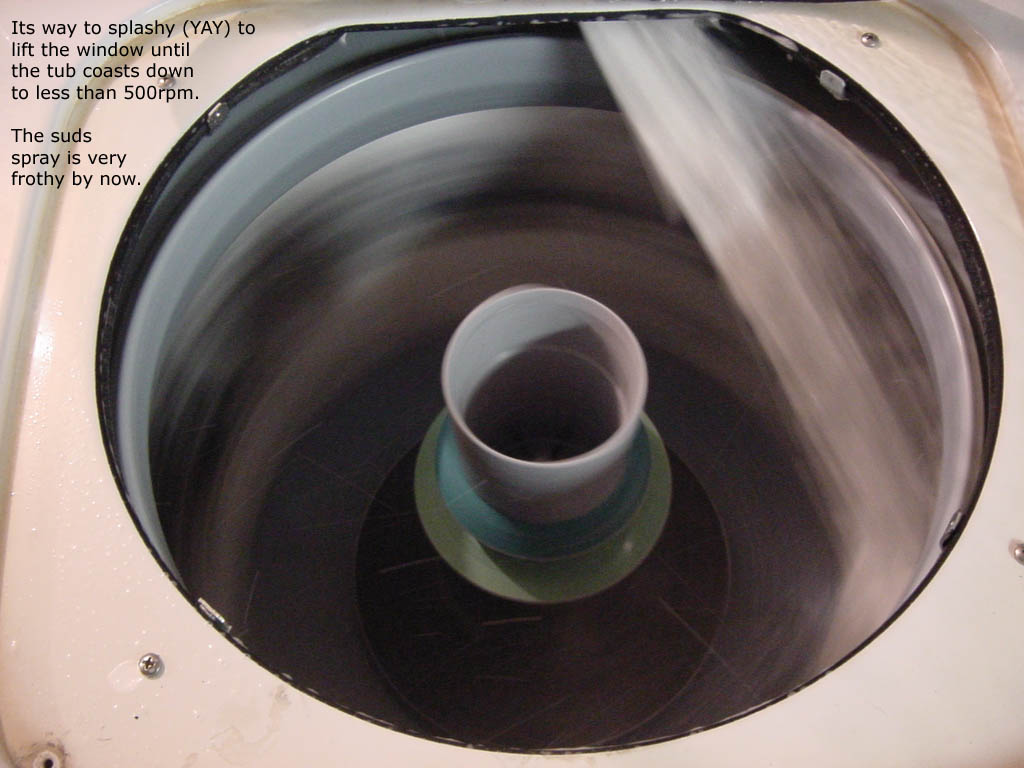

Would it be possible to control the motor speed? You could have a delicate cycle then. Hi Louis, actually it is possible, even with this powerful AC motor. Not so much in agitation, but spin is very easy to control. Playing with the software I can get the machine to spin from anywhere between 200 and 700 rpm easily without having to run the motor too much. With a wet wash load and no water coming into the tub, the tub will coast for over four minutes without having to turn the motor back on. So if I pulse the motor off between 30 and 60 seconds, then pulse it 10 to 20 seconds on, I can obtain a wide range of spin speeds. Yes now a 1140rpm Unimatic can gently spin my delicates at 250rpm! Now of course this wont work for agitation, but I can very easily have a delicate wash by pulsating for 30 seconds and soaking for two minutes, or some other combination like that. Tonight I added another water saving feature, I added a check box to the computer screen to tell the washer not to drain the rinse water from the outer cabinet after the final spin. Since I don't use fabric softener in towel and utility wash loads, I can pump the cool rinse water back up for the next cycle if I'm washing dark colors. That saves at least 12 gallons of water right there. Sort of a built in suds-saver, without having to reuse dirty wash water. The rinse water is nice and clear, ready for a fresh charge of detergent. | ||

Post# 95109 , Reply# 15 11/22/2005 at 00:35 (6,736 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

| ||

Comes to the Rescue!

Comes to the Rescue!