|

Thread Number: 42080

Maytag A408 putting ick on my clothes - help please! |

[Down to Last] |

| Post# 619715 8/24/2012 at 07:56 (4,263 days old) by EarthlyAmy (Barton, VT) | ||

We have a Maytag large capacity Dependable Care washer/dryer pair (in beautiful avocado) that was included with our house when we bought it in 2002. As there doesn't seem to be any repair people willing to work on these old workhorses in our area, I've been doing it myself. There are two issues I'm hoping to get some advice on: 1)The final rinse water never fully drains out during a regular wash cycle. I've gotten used to just going downstairs and turning the dial to the rinse/damp dry area of the Knits cycle to get the clothes rinsed out. Otherwise, they just sit in the dirty water until I remember about them.

2)Lately (for about 6 weeks) I'm seeing gray splotches and streaks on knits when I take them out of the washer. Seems to be worse on white and pastels. Some of the time it seems to be fine lint that I can scrape off with a fingernail, but last night it was more like a straight-up stain. The only resolution is to re-wash using Oxy-Clean and no detergent, but one bra didn't come all the way clean. There are evenly spaced gray dots on it, so this must have come from the holes in the tub, no? I've only ever changed the timer - is it a big deal to take out the inner tub to see what's going on? | ||

|

Post# 619723 , Reply# 2 8/24/2012 at 08:27 (4,263 days old) by Volvoguy87  (Cincinnati, OH) (Cincinnati, OH) |

||

Maytag.

The design of your washer changed relatively little from 1958-2006. The transmission changed around 1988, but the pump, belts, water valve, tub seal, bearings, motor, and a whole mess of other parts are still very much available. Most reputable service techs should be familiar with Maytag washers.

As a side note, check your washer's lint filter. It fits down the center of the agitator and the fabric softener dispenser cup sits atop the lint filter. Just grab the top of the lint filter and pull it out. It may be caked with crud if you've never cleaned it. I had to scrub mine with an old tooth brush. There are many folks here who say the Maytag lint filters are of limited value, but I find mine catches lint and is effective on pet hair. Also, if your pump is good, it's not a bad idea to remove the front panel of the washer and oil it. There is a screw on the front of the pump just below the impeller that doesn't attach to anything. Take it out and squirt in a few drops of Zoom Spout Turbine Oil and put the screw back. Oiling teh pump's bearings ought to be done once every few decades :) Dave | ||

| Post# 620218 , Reply# 3 8/25/2012 at 23:10 (4,261 days old) by AutoWasherFreak () | ||

|

Hmm learned something new. I didn't not know about oiling the pump. | ||

| Post# 621825 , Reply# 4 9/1/2012 at 15:32 (4,254 days old) by EarthlyAmy (Barton, VT) | ||

picture, please

Can anyone link to a diagram that shows me what the pump's impeller looks like? I read repair advice that said to stick a finger in it to make sure nothing was plugging it up. What if any hoses need to be removed in order to do this?

Just about to start some baby steps towards getting these two issues resolved (among others): 1: clean out screens at water intake hoses (it fills really slowly, especially hot and cold only washes) 2: check continuity of water intake valve (probably not the issue as it never drips water into the tub) 3: scrub out the lint filter with a toothbrush 4: check the belts and the mysterious pump impeller. Another question: do you really have to buy the spanner wrench to remove the agitator to inspect the tubs? The hubs has a collection of hex wrenches, will one of these do the trick? TIA for all your wisdom. | ||

| Post# 621893 , Reply# 5 9/1/2012 at 20:53 (4,254 days old) by EarthlyAmy (Barton, VT) | ||

update on this afternoon's labor

So I got #1 and #3 done on my list (above) but I'm finding the original problems still exist. I ran a cycle of hot water and bleach (to wash out any mold possibility on the outside of the inner tub) and then did a load of whites. Hubby's tighty whiteys got the gray splotches on some pairs - the ones in the bottom of the tub - but not on all. Is there anything rubber between the two tubs that could be disintegrating? And it won't drain the wash water at all on a regular cycle - it spins fine, but there's never any water gone when it's done spinning. It's weird that is works fine on the Knits cycle - although I sometimes have to give an extra spin/Damp Dry - but no other.

| ||

Post# 621910 , Reply# 6 9/1/2012 at 21:33 (4,254 days old) by Kenmore71  (Minneapolis, MN) (Minneapolis, MN) |

||

The fact that the machine isn't draining completely by the end of the spin cycle indicates that there is a problem with the drain system. This can be caused by 4 things:

1. A clog or kink in a hose which could exist anywhere between the drain opening at the bottom of the tub and whatever the hose ultimately drains into. 2. A clog in the pump itself (unlikely but not impossible). 3. A failing pump bearing which will make the pump stiff and turn too slowly. 4. The pump belt being WAY too loose such that it slips. In all honesty, before I tried to pull the tub out (a rather involved project), I would disassemble the whole water removal system (just 2 hoses and the pump). Flush out all of the hoses. Make sure the pump turns freely. Also, I would poke my finger and/or a screwdriver up into the outer tub very gently once I got the hose off just to be certain that there isn't a rogue stocking or handkerchief that leapt out of the inner tub and now resides at the bottom of the outer tub. If that IS is the case, gentle persuasion with a needle nose pliers or large tweezer might be able to extract it without removing the inner tub. As to the "ick" that is on the whites, that is a bit of a mystery to me. I don't think there are any rubber components between the tubs in a Maytag of that vintage (unless there is rubber between the agitator and its splining.) I think what you are dealing with here is the "ick" that is accumulating/growing in between the tubs from not draining completely on a regular basis. I think there is a good chance that if you get the whole water system cleaned out and possibly replace the pump that this problem will take care of itself. A properly functioning Large capacity machine should have the entire tub pumped out in 1-1/2 to 2 minutes tops and should be up to FULL spin speed of 618 rpm by 3 minutes into the "Damp Dry". | ||

| Post# 622412 , Reply# 7 9/3/2012 at 20:22 (4,252 days old) by EarthlyAmy (Barton, VT) | ||

A408 crime scene investigation

Well, I opened the front panel today and saw this:

Pretty nasty, right? Am I right in thinking this pump is not original? I took off the hose from the pump to the tub and checked it out. No blockage but whatever it's made of seems to be disintegrating as this plasticy-rubber hose was coated inside with little bits of itself. Two interesting observations: 1) I filled the tub with water only on the "small" load size, turned the dial to 5 minutes left on the regular wash cycle and let it go. Seems like an awful lot of water for a small load - tub was half-full. When it was supposed to spin I heard some water head out the drain hose but by the time it stopped spinning (still doing that well) there was about 2" of water still in the tub. Does the tub spin so fast that the water can't get out of the little holes in the tub? Or is the pump supposed to pull the water out? 2)the belts: I upended it and had a look at the 2 belts. The pump belt is a joke - it's so slack I can cross each side over the other by about 1/2". The belts were changed in 2009 and there's a notation on the bill:"needs brake/clutch, customer declined". Whenever the washer's finished (or it gets interrupted) there's a horrible squeal. This is my cue to go to the basement and turn the dial to "Damp Dry". Is this squeal the brake/clutch issue? How does one go about changing the pump belt when it's so very rusty? I'm afraid the pump won't have anything to cling to beyond a slim hope. Are we looking at replacing rather than repairing the washer?

| ||

| Post# 622413 , Reply# 8 9/3/2012 at 20:24 (4,252 days old) by EarthlyAmy (Barton, VT) | ||

more photos | ||

| Post# 622415 , Reply# 9 9/3/2012 at 20:27 (4,252 days old) by EarthlyAmy (Barton, VT) | ||

another one | ||

| Post# 622419 , Reply# 10 9/3/2012 at 20:40 (4,252 days old) by danemodsandy (The Bramford, Apt. 7-E) | ||

|

Pump and hoses | ||

Post# 622429 , Reply# 11 9/3/2012 at 21:15 (4,252 days old) by DADoES  (TX, U.S. of A.) (TX, U.S. of A.) |

||

|

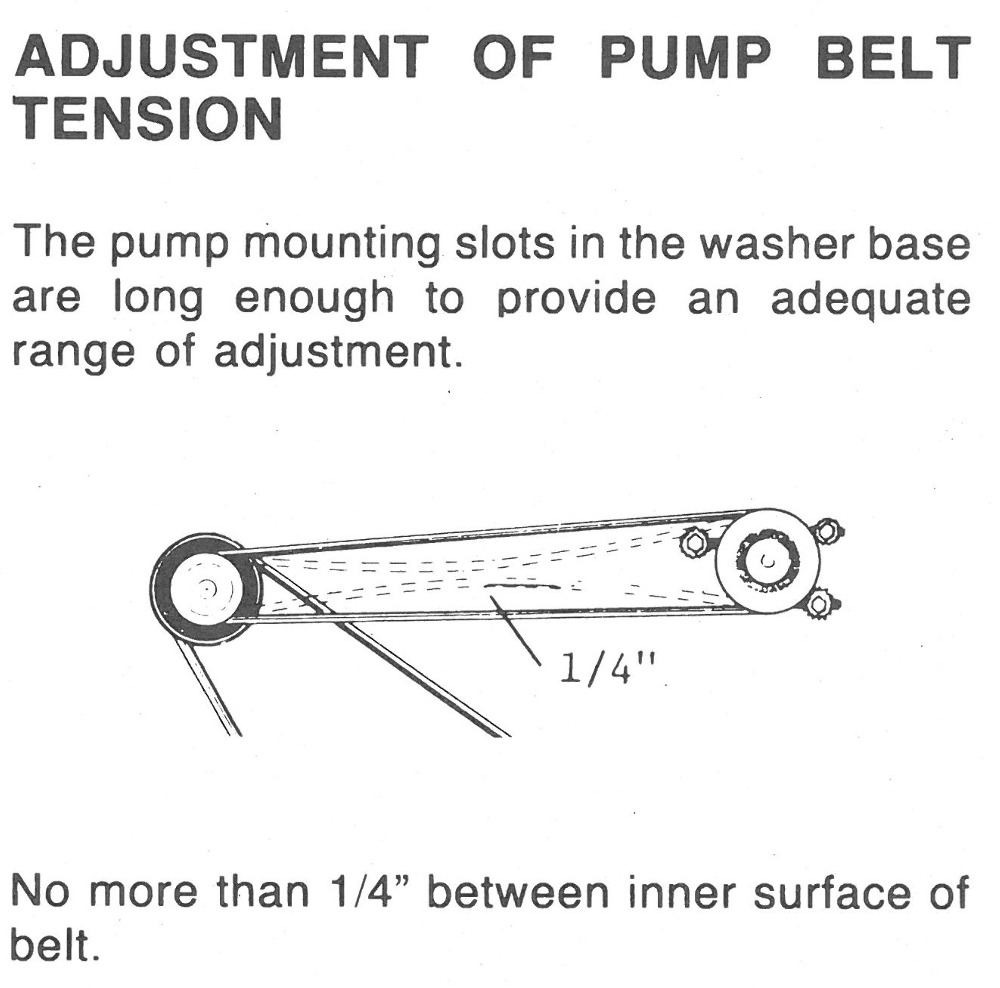

The belts simply slip off/on around the pulleys. Proper belt tension is set by loosening the three pump mounting screws slightly and shifting it along the mounting slots. The motor is mounted on a spring-loaded carriage. Correct belt tension is obtained by adjusting the pump position such that the motor carriage just begins to move when the pump belt is pinched at 1/4" distance halfway between the pulleys. Weight of the motor shifts it against the carriage springs when the machine is tilted further back, so best adjustment is by propping it up with something such as a 2x4 on edge for just enough space to reach beneath for pinching the belt. | ||

Post# 622430 , Reply# 12 9/3/2012 at 21:20 (4,252 days old) by Kenmore71  (Minneapolis, MN) (Minneapolis, MN) |

||

OK. Those pictures are instructive. I wouldn't worry too much about the squealing brake for now. That issue can be fixed more often than not with some heavy motor oil in the right spot.

The water pump is not original. The belt is WAY too loose. The pump belt should be on the loose side but not that loose. What you want to do is tip the machine back so that you have access to the belts and the the screws that hold the pump down. Loosen the screws on the pump and pull it to the right to increase the tension on the pump belt. The tension is correct when, in the MIDDLE of the pump belt, you can bring the two sides together to within a 1/4" of touching each other before you start to feel resistance and see the motor carriage start to move. See diagram below. Before you do this, you should take the belt completely off and make certain that the pump is turning relatively freely. As mentioned above you could oil the pump with turbine oil at this point but that is not critical to getting this machine back in service. In terms of the rust, this looks to be the result of years in a basement as possible earlier water system leaks. If you wanted to do a full restoration it should be taken care of but in all honesty, that baseplate has plenty of life left in it as is.

| ||

| Post# 622437 , Reply# 13 9/3/2012 at 22:08 (4,252 days old) by EarthlyAmy (Barton, VT) | ||

thanks for that!

Oh yay, a diagram! That helps immensely. It's good to know that the ol' girl isn't ready for the crusher just yet - not that we're in any kind of economic shape to replace it anyway. About the rust; yes, the two of them have seen a lot of water-related disasters in 35 years of service. The last of the Webster family to live in the house had a bad habit of letting the pipes freeze, among other things.

I'll update after adjusting the pump - I'd do it right now if I didn't have a 6:00 a.m. wakeup call! | ||

Post# 622454 , Reply# 14 9/4/2012 at 00:13 (4,252 days old) by pdub  (Portland, Oregon) (Portland, Oregon) |

||

Despite the rust...

One nice thing I see from underneath is no sign of the o-ring leaking from the bottom of the transmission shaft. If it were there would be that telltale oil spray underneath and I don't see any.

You could coat the rusty areas with some rust stop type paint and maybe use some lockwashers on the screws that hold the pump in place. This will help keep the pump from moving since the metal looks pretty rusty. Good Luck - Patrick | ||

Post# 622511 , Reply# 15 9/4/2012 at 07:47 (4,252 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

My thoughts exactly | ||

Post# 622534 , Reply# 16 9/4/2012 at 11:08 (4,251 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Well Used Maytag Washer Yes it looks like you may only to slightly tighten the pump belt and make sure that the pump turns freely. I like the comments from the last servicer that the washer needed a new clutch and brake and customer refused, that was a good desision as this washer does not have a clutch and the brakes almost never fail.

Most of the rust your machine has come from oversudsing the washer over the years which leaks down on the base plate coupled with the washer being in damp environments and while it looks bad I have seen much worse looking machines still running.

So hopefully the pump belt adjustment will do the trick, I certainly would not put any major work or money in this washer if its problems turn out to be more severe as there are many almost free used washers that can be found these days.

Mark I am curious why you think the water pump has already been replaced on this machine? | ||

Post# 622551 , Reply# 17 9/4/2012 at 12:57 (4,251 days old) by Tomturbomatic  (Beltsville, MD) (Beltsville, MD) |

||

|

this washer does not have a clutch Maytag like some other brands, uses the belt as a clutch. As they wear down, they have to be replaced, but it is a simple job. | ||

Post# 622577 , Reply# 18 9/4/2012 at 16:14 (4,251 days old) by kENMORE71  (Minneapolis, MN) (Minneapolis, MN) |

||

John, I think it has been replaced because the hose clamps are not the factory clamps. I would find it highly unusual to change out those clamps without changing the pump. Also, initially I thought the fact that the pump was a non-repairable one-piece meant it was changed out later, but in further research I found out that the one-piece non-repairable pump came along about 1977. So, the pump could be original but those hose clamps still make me suspicious.

| ||

Post# 622602 , Reply# 19 9/4/2012 at 18:54 (4,251 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

A408 MT Washer Pump Mark the hose clamps that mt used often rust and break and cause a water leak on machines that experienced lots of corrosive overflow. As a service tech for all these years I don't replace a MT DC water pump every five years [ in fact I dough that I have replaced a dozen in my whole working life ] but I do replace a lot of hose clamps.

In any case it does not matter, I was curious as to your thinking., All the best John. | ||

| Post# 622623 , Reply# 20 9/4/2012 at 20:40 (4,251 days old) by EarthlyAmy (Barton, VT) | ||

Oh crud!

As you all might have guessed I didn't get very far in my attempt to adjust the pump. I cannot budge any of hex-head screws in spite of trying Liquid Wrench, and trying to scrape away what loose rust there is. It feels like (since I'm doing all this by feeling underneath) somebody added lock nut washers when they installed the screws, which are also completely rusted. There just isn't enough metal left to get a grip on the things - I can't even tell what size the buggers are! Two screws on the front (one is the grounding wire) fit a 8mm socket, but not the pump screws. Even if I could get the thing unscrewed it looks to me like the pump is already as far to the right as it will go.

Options, anyone? I could cut off the screw heads with my Dremel but doesn't really solve anything, does it? Would a slightly smaller belt (40 - 39 1/2") do the trick if this stubborn thing refuses to budge? | ||

Post# 622691 , Reply# 21 9/5/2012 at 06:35 (4,251 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

A408 MT Washer Pump Amy you will probably have to cut the screw heads off and get another pump and use some washers and new screws to attach it, or if the belt is that loose compare it to a new new belt as it may have stretched or just get a slightly smaller belt, the pump belt on MT washers is nothing special you could get one at the hardware store.

I wish you were closer as we throw away MTs and other washers all the time and you could recycle a few parts to keep yours going for next to nothing. | ||

| Post# 622798 , Reply# 22 9/5/2012 at 17:04 (4,250 days old) by EarthlyAmy (Barton, VT) | ||

As Dorothy Parker once said, "What fresh hell is this?&#

Okay. I got a 3/8" x 40" lawnmower belt from the auto parts store. Got that one on way easier than the slightly-too thick 40" v-belt from the hardware store. Put in a couple of towels on a small load to try it out after getting everything all hooked up again. Wow! the pump is churning away so vigorously the drain hose almost jumped out the outlet pipe. EXCEPT, no agitation (just mine) and no spinning - on any cycle. What the hell? Shut everything down, tipped it back and had a feel underneath. Shee-it, now the motor pulley belt is all loosey-goosey. What happened? It didn't feel like that when I put on the new green belt. Le gros sigh...

| ||

Post# 622817 , Reply# 23 9/5/2012 at 17:42 (4,250 days old) by rp2813  (Sannazay) (Sannazay) |

||

| ||

| Post# 622826 , Reply# 24 9/5/2012 at 18:05 (4,250 days old) by EarthlyAmy (Barton, VT) | ||

what to do

With the pump stuck where it is, what to do about a too-tight belt? It's not THAT tight - I can squeeze the 2 sides together. Should I run a bunch of water only-loads and hope it stretches out just enough to get the motor pulley back in action? It doesn't sound good when it's whirring but not spinning.

| ||

| Post# 622832 , Reply# 25 9/5/2012 at 18:28 (4,250 days old) by danemodsandy (The Bramford, Apt. 7-E) | ||

|

Amy:

Did you also replace the drive belt in addition to the pump belt?

If you did, I hope you used a genuine Maytag belt. Any other kind of belt will cause problems; a Maytag drive belt is designed to slip at certain points in the cycle, and grab at other times, eliminating the need for a clutch. If you replaced the drive belt with a non-Maytag belt, this could be the source of some of your problems. The pump belt is, as others have said here, not critical, though its adjustment is. And as a matter of maintenance, you should replace the drive belt anyway. If it's worn, it could be slipping too much. The combination of a new pump belt that's a little tight and a worn drive belt that's a little loose could be what's causing your no-spin condition and whirring. A genuine Maytag drive belt is not expensive, and most appliance parts places will have it in stock. Online sources are abundant. | ||

Post# 622838 , Reply# 26 9/5/2012 at 19:18 (4,250 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

A408 MT Washer | ||

| Post# 622873 , Reply# 27 9/5/2012 at 21:15 (4,250 days old) by EarthlyAmy (Barton, VT) | ||

to danemodsandy:

No, I didn't replace the motor drive belt - both were only 3 years old, so I'm surprised the pump belt needed replacing so soon. I don't think the stretched out pump belt was a Maytag part, so I'll probably have to order a set online. Ain't no nothing-to-do-with-all-my-spare-parts repair people in my neck of the woods.

So, next question: given that I can't move the pump at all, how does one go about changing both belts, which I'm sure I'm going to have to do sooner or later. | ||

| Post# 622955 , Reply# 28 9/6/2012 at 09:03 (4,250 days old) by EarthlyAmy (Barton, VT) | ||

Allswell - at least for now

So I had to destroy the green lawnmower belt to get it off the pump - there's $13 down the drain. But it just so happens that I found the original Maytag pump belt from the 2009 replacement - good thing we never throw anything away! A little glazed for sure, but I heard from you folks the pump belt isn't as important as the drive belt, so I just threw it back on. And it's all working fine - even draining the tub fully on a regular cycle, something we haven't seen for a couple of years. I also oiled the pump. Once I push the machine back and get it leveled (it's pitched forward about 1/4") it's bound to go out of whack somehow - maybe I should just tiptoe away and leave it?

| ||

| Post# 622995 , Reply# 30 9/6/2012 at 14:04 (4,249 days old) by EarthlyAmy (Barton, VT) | ||

maybe I should look into this one?

$50 in Greenfield, MA. Hubby works south of Boston during the week - I could get him to "pick it up" on his way home tomorrow night ;-)! Maybe we're going to have to invest in a hand truck, too.

CLICK HERE TO GO TO EarthlyAmy's LINK on Westernmass Craigslist | ||

Post# 623022 , Reply# 31 9/6/2012 at 15:27 (4,249 days old) by rp2813  (Sannazay) (Sannazay) |

||

Get It! | ||

| Post# 623028 , Reply# 32 9/6/2012 at 15:47 (4,249 days old) by EarthlyAmy (Barton, VT) | ||

I know, right?! | ||

Post# 623035 , Reply# 33 9/6/2012 at 16:11 (4,249 days old) by akronman  (Akron/Cleveland Ohio) (Akron/Cleveland Ohio) |

||

questions | ||

| Post# 624688 , Reply# 34 9/13/2012 at 14:21 (4,242 days old) by EarthlyAmy (Barton, VT) | ||

NOS

Just one more question for all y'all before this thread is archived: would 35 years in a plastic bag make Maytag belts go bad? A seller on eBay has some NOS belts - although I haven't confirmed this - so I wondered if the passage of time might make the rubber brittle or crumbly or whatever. Don't want to get the "meh" belts (made in Mexico) if I can get ahold of genuine Maytag ones.

CLICK HERE TO GO TO EarthlyAmy's LINK on eBay | ||

Post# 624774 , Reply# 35 9/13/2012 at 21:48 (4,242 days old) by pdub  (Portland, Oregon) (Portland, Oregon) |

||

| ||

Comes to the Rescue!

Comes to the Rescue!