|

Thread Number: 32606

Miele W1918 Bearings |

[Down to Last] |

|

| Post# 491655 , Reply# 1 1/26/2011 at 13:43 (4,930 days old) by grahamW () | ||

|

Video I've uploaded a video that shows the issue with my washer. CLICK HERE TO GO TO grahamW's LINK | ||

Post# 491685 , Reply# 2 1/26/2011 at 17:14 (4,930 days old) by Launderess  (Quiet Please, There´s a Lady on Stage) (Quiet Please, There´s a Lady on Stage) |

||

Have you contacted Miele in Canada for part information?

Though an "older" unit the 19XX series isn't vintage enough for Miele to stopped offerng parts all together, though what they have in stock may be limited. Also once a model starts getting up there (like my 1070) Miele North America will cease inporting spare parts, thus leaving only whatever inventory is left. Once this is gone that is that. However being as this may, not sure if one can request Miele import a part not in stock, which they will do for current items. IIRC someone here in the group or perhaps somewhere on the Internet posted how they changed the bearings on their Miele 1918. It is not a job for the faint hearted. For a start you will require a winch or some other way to get those heavy tubs out of the cabinet. IIRC, Miele does this sort of repair work here in the States, but only at their New Jersey workshop. | ||

Post# 491761 , Reply# 5 1/26/2011 at 23:29 (4,929 days old) by Launderess  (Quiet Please, There´s a Lady on Stage) (Quiet Please, There´s a Lady on Stage) |

||

Thing Is

Until the machine is opened and examined you don't know what you are dealing with.

Yes, it could be as "simple" as the bearings being gone, but what about the belt? Shaft? Pulley? Other parts? Would be a shame to order say a bearing seal kit only to find out there is more going on in there. Then your options are to leave the machine in bits until you can source parts, or put it back together only to have to redo the entire thing again. While your machine is out of warranty, Miele does over a limited warranty of a sort on parts and work done by their techs. If you do the job yourself with generic parts, all bets might off should something happen down the line. As for ordering parts from the EU, while the 1918 is an "older" unit therefore someone might be looking to unload various things cheaply, not all things inside your machine are "old" design. If Miele is still using bearing, spiders, et al from that design in current units, you may or may not see a difference in price. Another thing to consider is Miele North America prices it's parts at cost from when they were imported, not today's exhange rate. Maybe the Canadian dollar is doing better against the Euro than ours (USD), but then again consider you will be paying shipping and VAT on top. If you need larger parts such as say a spider shipping may be either costly nor not possible out of some countries. Getting anything "large" out of Germany for instance is next to impossible. If it won't fit in the largest sized parcel post box, most German sellers of anything won't even bother. Regarding the link to seller of bearings: For this to work you'll need the corresponding EU model to your W1918. Before going off on a tear, rather than self diagnosing from the "outside" (and I say this as one who had dealt with a few "vintage" Miele washer problems), I'd either call out Miele service or "pop the bonnet" and see what is going on inside. Used older Mieles and often even newer models do pop up on eBay and CL all the time. You might be able to find another 1918 for what it would cost in parts to repair the one you have. Contact Miele tech support, and see if you can get one of the old heads, not a hot shot youngster. Someone familiar with your unit and start asking questions. Ask for a parts diagram showing the tubs and or drums/bearing areas. Miele used to email/fax such information free of charge, don't know if they still do. Once you get the above, go over them to get a feel of how the unit is put together. You might also seek out a Miele affliated service person. We have them here and they are former Miele techs whom have gone out on their own, and or free-lance repairmen who have been trained to work on Miele appliances. | ||

| Post# 491884 , Reply# 10 1/27/2011 at 13:57 (4,929 days old) by 3beltwesty () | ||

|

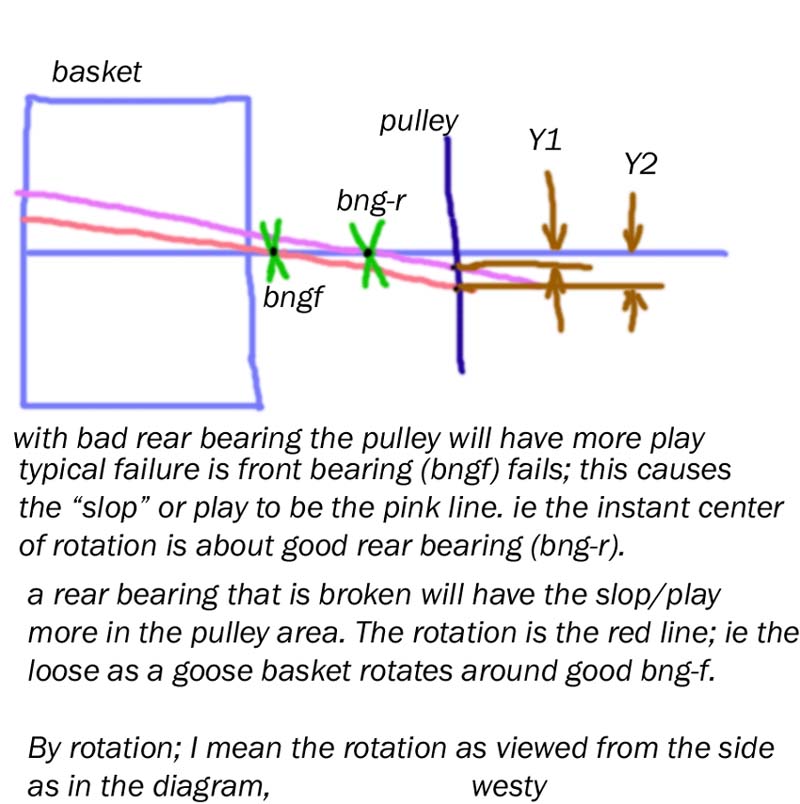

pulley movement with both types of bearing failures Hope this makes it clear

| ||

| Post# 491886 , Reply# 11 1/27/2011 at 14:00 (4,929 days old) by 3beltwesty () | ||

|

instant center If one grabs the basket and moves it up and down; the point it rotates in space is the good remaining bearing. | ||

| Post# 492466 , Reply# 15 1/29/2011 at 18:50 (4,927 days old) by eddy1210 (Burnaby BC Canada) | ||

I have a Miele tech friend here in Vancouver, and there's nothing different or "flawed" about the bearings in the 1918 as opposed to the other models. I too have a W1918. The factors involved are the 1600 rpm spin, which customers use all the time for cottons, and the fact that the 1918 has no OOB control, other than a tach on the motor that reduces the spin speed if it's overly unbalanced. I have scratches and scars on my window glass to prove it! So, it seems to be a combinations of factors that lead to premature bearing wear. | ||

| Post# 492645 , Reply# 18 1/30/2011 at 14:32 (4,926 days old) by limey () | ||

|

Bearing failures and causes Graham, I have forwarded a booklet put out by SKF on the above subject to your email. Regards | ||

| Post# 496083 , Reply# 25 2/12/2011 at 22:06 (4,913 days old) by grahamW () | ||

|

2nd thought My previous msg didn't make any sense... In retrospect, I think a gear puller on the cast spider with a little heat should get the spider+bearings free of the shaft. | ||

| Post# 497255 , Reply# 31 2/17/2011 at 21:10 (4,908 days old) by grahamW () | ||

|

One bearing out Andrew, can you be more specific about what photo you would like? I have taken quite a few shots as I progress. Eg: Here's the spider with the outer bearing (#9 in diagram above): It was relatively easy to pull.

| ||

| Post# 497256 , Reply# 32 2/17/2011 at 21:13 (4,908 days old) by grahamW () | ||

|

The inner bearing... The inner bearing, however, is proving more difficult. And, yes, that is a piece of the outer race...

| ||

| Post# 497267 , Reply# 34 2/17/2011 at 22:32 (4,908 days old) by Pingmeep () | ||

|

After looking for similar problems with the W1918 I came across this thread on gardenweb. Sounds similar to your problem. CLICK HERE TO GO TO Pingmeep's LINK | ||

| Post# 497411 , Reply# 37 2/18/2011 at 12:42 (4,907 days old) by vacfanatic () | ||

|

Spiders Here are a couple of photos of the spider that is actualy attached to the drum itself. There is also the cast X piece that you already took off from the back of the drum. I'm curious to see what your inner tub's spider is made of.

| ||

| Post# 497412 , Reply# 38 2/18/2011 at 12:43 (4,907 days old) by vacfanatic () | ||

| ||

| Post# 497416 , Reply# 39 2/18/2011 at 13:13 (4,907 days old) by 3beltwesty () | ||

|

What is the white stuff that that is one the lower image's drum spider by the shaft? Can you post a higher res image of spider? I want to see if if is a casting or forging, or machined. | ||

| Post# 497759 , Reply# 47 2/19/2011 at 19:15 (4,906 days old) by grahamW () | ||

|

Another photo Here's the bearing which shows the swiss-cheese groove I needed to make. A few light hammer taps with a punch and it was free.

| ||

| Post# 497760 , Reply# 48 2/19/2011 at 19:17 (4,906 days old) by grahamW () | ||

|

I'll clean up the inner drum and post a few better photos of the spider but here's what it looked like when I pulled it.

| ||

| Post# 497761 , Reply# 49 2/19/2011 at 19:18 (4,906 days old) by grahamW () | ||

|

A close-up of the scaly, white residue:

| ||

| Post# 497763 , Reply# 50 2/19/2011 at 19:23 (4,906 days old) by grahamW () | ||

|

Here's a final photo showing the shaft where the troubled, inner bearing was:

| ||

Post# 497992 , Reply# 56 2/20/2011 at 14:47 (4,905 days old) by Launderess  (Quiet Please, There´s a Lady on Stage) (Quiet Please, There´s a Lady on Stage) |

||

".... Back of Trucks.."

This isn't the sort of thing Miele will do in a person's home, not at least in the United States anyway.

Should Miele decide a bearing replacement is required, and will do the work at all, the washer must return to the corporate workshop in New Jersey. Methinks the only way Miele would do this work is a warranty repair and who knows if even then. Probably would have been less bother simply to give the customer a new washer. Cost of transporting the unit to and from NJ is about $1500 USD, then one would have to add the costs of parts and labour. When all is said and done you are probably looking at near or over 2500 to 3000 USD. Being as this may, there seems to be quite allot of bearing replacement work done on all models of front loaders in Europe, even as a DIY project. To be fair those on that side of the pond have had >thirty years of front loaders as the main washing machine. So it is very likely many repairmen have the tools "in back of their truck" or perhaps their own workshop for the job. | ||

| Post# 498050 , Reply# 60 2/20/2011 at 20:20 (4,905 days old) by grahamW () | ||

|

A laundry tub, in a laundry tub...

| ||

| Post# 498051 , Reply# 61 2/20/2011 at 20:22 (4,905 days old) by grahamW () | ||

|

After the first pass... the rust appears.

| ||

| Post# 498052 , Reply# 62 2/20/2011 at 20:23 (4,905 days old) by grahamW () | ||

|

I decided at this point, to remove the spider (3 bolts running the length of the drum, inside the paddles). After some more scrubbing:

| ||

| Post# 498054 , Reply# 63 2/20/2011 at 20:26 (4,905 days old) by grahamW () | ||

|

A few close-ups of the rust spots: This photo also shows the bottom of the shaft where the seal would sit. At the top of the photo, you can see a bit of corrosion where the inner drum bearing was.

| ||

| Post# 498056 , Reply# 64 2/20/2011 at 20:27 (4,905 days old) by grahamW () | ||

|

Top view of the large rust spot, shown on the left above:

| ||

| Post# 498058 , Reply# 65 2/20/2011 at 20:32 (4,905 days old) by grahamW () | ||

|

Here's the other side of the spider/shaft. Again, you can see the bottom of the shaft (note, there is no discolouration. It is just the reflection of the rust patches) along with the ring of corrosion just below where the inner drum bearing was.

| ||

| Post# 498059 , Reply# 66 2/20/2011 at 20:33 (4,905 days old) by grahamW () | ||

|

The back-side of the spider has only a little rust.

| ||

| Post# 498094 , Reply# 73 2/20/2011 at 21:38 (4,905 days old) by grahamW () | ||

|

3beltwesty, here's another photo of that area. It doesn't look like a crack in person. In person, it looks like an imperfect weld bead going all around the top/bottom edge of the spider.

| ||

| Post# 498097 , Reply# 74 2/20/2011 at 21:39 (4,905 days old) by grahamW () | ||

|

Another of the spider.

| ||

| Post# 498106 , Reply# 75 2/20/2011 at 22:06 (4,905 days old) by cfz2882 (Belle Fourche,SD) | ||

|

nice spider!-no corrosion problems there,almost looks like forged steel the way the shaft is welded on.Could be "cast"steel also.Looks like the seal sleeve is replacable too,real quality. | ||

| Post# 498227 , Reply# 81 2/21/2011 at 12:42 (4,904 days old) by GrahamW () | ||

|

limey, thanks for your input. | ||

Post# 498336 , Reply# 83 2/21/2011 at 17:42 (4,904 days old) by Launderess  (Quiet Please, There´s a Lady on Stage) (Quiet Please, There´s a Lady on Stage) |

||

"Aunt Bea, Call Da Man" *LOL*

As Andy Griffth would say.

Contact Miele tech support and explain what you've done so far and explain (or if they will allow send pictures), of what the spider and or other parts look like. You need to find out from those whom know best what something should or should not look like. As with top loaders here, there is normally a reason parts come as a "set",and it takes some experience to know what old parts can stay or go. FWIW, one can find Miele spiders off the shelf (as I've said often about other such parts), in the UK and EU. However at $235 British Pounds,(roughly 402 USD)cannot imagine what Miele USA will charge, that is if they will even sell you the part. Given it's size, shape and weight, shipping is going to be dear as well. Another option, depending upon your language skills of course, is to post a query on one of the Yahoo or other "appliance" or "washer" groups in Germany or other parts of western Europe. You will probably find a few persons with experience in these matters,including perhaps former Miele employees and or trained servicemen. Unlike North America where Miele has tight control over almost every aspect of sales, parts and service, on the other side of the pond things are different. | ||

| Post# 498363 , Reply# 84 2/21/2011 at 18:59 (4,904 days old) by cfz2882 (Belle Fourche,SD) | ||

|

spider looks to be in very good condition from what i can see-i'd replace the seal sleeve and run it-looks like a real quality machine well worth the repair effort. | ||

Post# 498573 , Reply# 87 2/22/2011 at 16:16 (4,903 days old) by Launderess  (Quiet Please, There´s a Lady on Stage) (Quiet Please, There´s a Lady on Stage) |

||

Maybe. OTHO Maybe Not.

Bearing replacement on front loading washers on the other side of the pond are jobs some repair persons love, others hate.

There is a reason why so many parts for this sort of job are available DIY, just the same as seal replacement kits for top loaders here; for the amount of work involved versus price it often does not pay for a service call. Even under warranty (usually the only way most will bother), a repair is alloted a certain amount of time. This can be divided into sessions, say "X" to diagnose, "X" to strip down, "X" to replace/repair, and finally "X" to put everything back together... Washer makers or whomever is paying for the warranty call, will allot an experienced service person (and his helpers if required) usually only one to two hours for "bearing replacement". If upon getting the washer apart things are more than what was supposed (bent spindle, spider, etc), then things will get interesting. Even if the bearings have gone, and or were causing the original complaint, if other problems are found that if not addressed would simply wear out the replacment parts again quite soon, a choice has to be made. Either pay for the additonal parts and or labour, or scrap the whole idea and buy new. If one is paying for the service call out of pocket, it probably will run >500 USD excluding parts. With the entire job coming near either the cost of a "decent" new washer or darn close to a hefty down payment. Unlike the United States, front loaders of "average" quality do not cost an arm and leg in the UK/EU. This is why bearing replacments are most always DIY, warranty service calls. For the average person it simply does not pay. Miele washers in particular are problem due to the rather properitary nature of the company. Unlike other brands where one part may work for several machines, Miele parts are only for their machines. Nor is the company terribly liberal with advice and such. If the spider needs to go (and am not saying the one pictured above does not does not), and it simply is put back into service, what happens several months or a few years later? If the thing goes and or damages the new bearing/seals you are looking at another expensive service call. | ||

| Post# 498607 , Reply# 90 2/22/2011 at 19:06 (4,903 days old) by cfz2882 (Belle Fourche,SD) | ||

|

seal collet miele does not sell that collet as a seperate piece? | ||

Post# 498612 , Reply# 92 2/22/2011 at 19:14 (4,903 days old) by Launderess  (Quiet Please, There´s a Lady on Stage) (Quiet Please, There´s a Lady on Stage) |

||

Well, That Depends

Upon what you consider the useful life of front loading washing machine.

Miele boasts (at least as far as their older models are concerned), some of the longest, if not the longest life span. While the oft used quote is "twenty years tested performance", what Miele actually means that under tested conditions (about two or three wash loads per day), a washer of a vintage period should last on average about twenty years. However in your case, as probably many others whom have purchased used Miele units, the conditions of previous use are known. Constant over loading of the washer, use of wrong and or too much detergent, and or other forms of "abuse", would cause parts to wear out sooner than they should. From what one has read on various European washer forums, lower final spin washers tend on balance to out last those with speeds >1200. The 1900 series was Miele's first with spin speeds at 1600rpms. As noted upthread using high speed spin speeds with unbalanced loads more than one should, is going to have an effect on some parts. My guess is somewhere in Germany at sometime, someone sat down and ran the numbers. How long should bearings, seals, shaft et al other parts last under "normal" condition, cost of repair (if parts go under warranty), expected duty life cycle, and other factors to reach a number for making part specs. | ||

Post# 498672 , Reply# 93 2/23/2011 at 01:34 (4,902 days old) by sudsmaster  (SF Bay Area, California) (SF Bay Area, California) |

||

That scale is most likely limestone - the product of washing soda (sodium carbonate) combining with calcium and/or magnesium in the tap water AND in the dirt in the soil on the laundry and forming an insoluble precipitate.

One way to help prevent this sort of thing is to use a good non-precipitating water softener, such as STPP, with every load. As for the spider - I'm wondering if it's cast magnetic stainless steel. That sort of alloy can be corroded, a bit, but nowhere near as quickly as a regular steel would get corroded. When my Neptune had its three year mark rebuild, I got to see the spider. It's aluminum and rather beefy, but it had turned jet black with all the hot water loads, perhaps also due to the phosphates in the mix. The original spider had cracked (probably a mfg defect). It's been running fine with phosphates on the replacement spider for the past seven years. As for pulling the bearing... I would suggest using a three-jaw puller next time (Pep Boys has a good one for about $50). Less chance of the bearing cocking and making the removal more difficult than it need be. And of course I'm sure you must have used a penetrant like PB Blast, which is great for freeing corroded fasteners etc. | ||

Post# 498678 , Reply# 95 2/23/2011 at 04:28 (4,902 days old) by Launderess  (Quiet Please, There´s a Lady on Stage) (Quiet Please, There´s a Lady on Stage) |

||

Well I'm No Model But No One Disputes How I Wear Clothe

*LOL*

Methinks the shaft does not come separately and is part of the inner drum as a unit. Thus one would need a new inner drum & the rear drum bearing assembly kits/clips, and so froth. One says this because to our mind's eye how could the shaft, a part which literally supports the weight of the tub, especially when full of wet laundry, be "replaced" without making sure a new part was so affixed to the drum as to continue that function. Far eaiser to do a repair by swapping out drums and replacing bearings/seals/clips, etc than pfaffing around trying to remove and replace an old shaft. I mean who is going to do the welding? | ||

Post# 499523 , Reply# 97 2/26/2011 at 19:46 (4,899 days old) by Launderess  (Quiet Please, There´s a Lady on Stage) (Quiet Please, There´s a Lady on Stage) |

||

Well I Guess We Will Never Know!  | ||

Post# 500153 , Reply# 100 2/28/2011 at 18:13 (4,897 days old) by Launderess  (Quiet Please, There´s a Lady on Stage) (Quiet Please, There´s a Lady on Stage) |

||

Am Sorry To Hear....

By contractual obligations Miele USA will not render service, advice, sell parts to etc anyone in Canada, and vice versa for the Canadian Miele. I know this because once called the later about ordering some parts (back when the USA was high against the CDN $), and was promply told the lay of the land.

Was also told if you purchase a Miele appliance in either country and move across the border, don't look for warranty service etc in your new home, if anything. Again see above. Miele Canada probably never had many of the spiders and or drums to begin with, and as the series went out of production, no further orders were placed. It could also be the parts were ordered as needed from Germany for a warranty repair (the only way Miele does this sort of work down here), and now with the series out of production they don't bother anymore. Do feel your pain and am that sorry you went into all that effort only to be let down at the last moment. Whilst ordering the spare bearings and seals from Europe *may* be doable, I'm with you on forgetting about the drum/spider. They are too large, heavy and would have to go probably via freight. This would not be inexpensive. | ||

| Post# 500223 , Reply# 101 3/1/2011 at 04:44 (4,896 days old) by limey () | ||

|

And The Moral Of The Tale Appears To Be: Don't buy a Miele in North America unless you really know what you may be letting yourself in for. | ||

Post# 500240 , Reply# 102 3/1/2011 at 06:59 (4,896 days old) by Launderess  (Quiet Please, There´s a Lady on Stage) (Quiet Please, There´s a Lady on Stage) |

||

Er, Not Exactly

I'd add "used" to that phrase, and even there it doesn't apply here.

OP stated upthread when he purchased the unit the seller explained there were some "issues" with the washer, but didn't know all of them. Many persons do not realise when bearings are going, and simply continue to use the washer until things get bad, such as rust and or other stains on laundry, and or the final certain "jet taking off" sound of bearings totally shot. If the unit was new back in it's day and under warranty, Miele would have been contractually bound to either fix the problem, or offer a solution. Usually the later involves simply replacing the entire unit with a new one. | ||

| Post# 500324 , Reply# 105 3/1/2011 at 12:11 (4,896 days old) by 3beltwesty () | ||

|

Grahm; when you pull the elctronics you might spot some 4 digit electrical data codes on IC chips etc and find a clue as the rough date the washer was made. ie a 9803 date is 3rd week of 1998 | ||

Post# 500509 , Reply# 107 3/2/2011 at 01:21 (4,895 days old) by Launderess  (Quiet Please, There´s a Lady on Stage) (Quiet Please, There´s a Lady on Stage) |

||

Parts Spare Machine

Not a bad idea, considering the motor alone will run $1500 USD or more.

Am dreading what will happen when my 1070 gives up it's motor or bearings. Lots of the 19XX series are being got shot of down this way as well. Methinks now that Miele offers larger sized washers,many consumers so inclinded feel they can trade up and not suffer "Miele Withdrawal". | ||

Post# 500808 , Reply# 108 3/3/2011 at 00:51 (4,894 days old) by sudsmaster  (SF Bay Area, California) (SF Bay Area, California) |

||

I purchased a used 1918A off Craigslist for $200 about five years ago. They had two for sale at the time; I wish I had gotten both! It's an excellent machine, and has given me no problems. I generally run one load a week in it - whites, at 160F. It does a great job with them.

I also have three W1065 washers. Only two are hooked up, though, and sometimes I'll run one of them along with the 1918A if I have extra stuff. The main washing goes on with a Maytag Neptune 7500 - which can handle larger loads and more bulky items, and is fine for things like colors and perm press that don't need high temps or high spin speeds but do benefit from more drum space to "spread out" in. Shop duds with metal chips or dust on them go into one of the W1065's, so as to try to keep that stuff out of the regular laundry cycle. The W1065's were even cheaper. I got two for $50 each, and another one (rip off in comparison) for $200. One of the $50 ones also included a stacked dryer, also not hooked up yet. Anyway, aside from bragging about my Miele collection, yes, you can find them used for $200 or less on Craigslist or other venues. As usual, caveat emptor, but for that kind of money you're not going to be too far in the hole if they don't work out. I do wonder, however, if it's not possible to get the bearings from a place like Grainger or other supplier. My understanding is that bearings are standardized, and if you have the right dimensions/specs you can get a generic version that might do the trick. Don't know about the seal, though. The damage to the shaft is more problematic. I suppose if it's not too bad it could be turned and polished but that would require a rather large lathe. | ||

| Post# 501061 , Reply# 109 3/3/2011 at 20:28 (4,894 days old) by 3beltwesty () | ||

|

Bearings are easy to find; it is the water SEAL that is the . | ||

| Post# 501079 , Reply# 110 3/3/2011 at 21:43 (4,894 days old) by cfz2882 (Belle Fourche,SD) | ||

|

seal depending on design,seal may or may not be easy to get from non-miele sources-when i did a bearing job on a 1998 "frigilux"i was able to get a suitable seal from my local "carquest"auto parts store,it had the same double lip design as original-cost around $13.00 Frigilux used 6306 and 6307 bearings-plenty stout. | ||

| Post# 501112 , Reply# 111 3/3/2011 at 23:41 (4,893 days old) by 3beltwesty () | ||

|

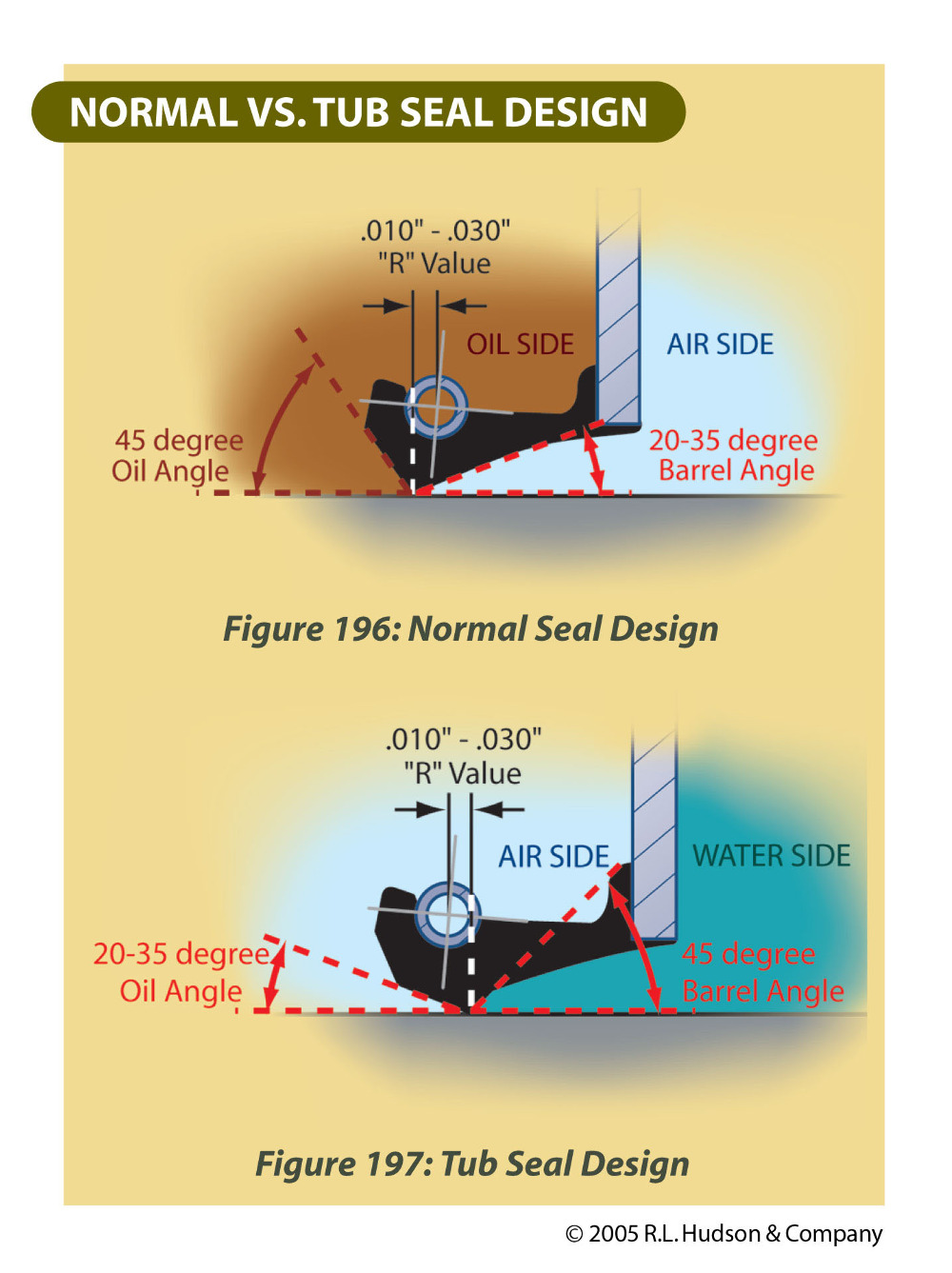

Washing machines have a special lip design Seals in washing machines have a different lip angle than say a wheel bearing seal. | ||

| Post# 502935 , Reply# 112 3/10/2011 at 05:37 (4,887 days old) by limey () | ||

|

Seals, Lip Angles To 3beltwesty. Re your post # 501112 You are one up on me there. Do you have any other details, websites with details etc. Any info gratefully devoured. Thanks | ||

| Post# 502956 , Reply# 113 3/10/2011 at 08:55 (4,887 days old) by 3beltwesty () | ||

|

Seal design . CLICK HERE TO GO TO 3beltwesty's LINK

| ||

| Post# 502966 , Reply# 114 3/10/2011 at 09:45 (4,887 days old) by limey () | ||

|

Many Thanks To 3beltwesty. Great info. really apreciate that. | ||

Post# 502983 , Reply# 115 3/10/2011 at 11:26 (4,887 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

MIELE SEAL AND BEARING FAILURE This has been an interesting disassembly and tear down. This problem was caused by a failure to use enough detergent for water conditions which caused the heavy mineral buildup which caused fast seal ware and resulted in bearing failure when water got past the seals. I have seen this hundreds of times. The solution is not so much periodic washer cleaning as just doing laundry properly in the first place. If you pay attention to what is going on in your washer or dishwasher it should never be necessary to run cleaners through them. Doing laundry improperly and then trying to clean up the mess periodically would be like not changing your cars oil for 50,000 miles at a time and trying to flush out the mess afterwards, the damage is already done its largely too late. | ||

| Post# 503033 , Reply# 118 3/10/2011 at 16:54 (4,887 days old) by pierreandreply4 (St-Bruno de montarville (province of quebec) canada) | ||

your lucky to be able to have it fix

your can consider yourself lucky to be able to have it fix as most repair comp today would say to buy a new machine 1 of my aunts had to have a tech come to fix something on her fridge is it was not for her recipe and warrenty papers the tech would of told her to buy a brand new fridge well i do hope that you will be able to have it fix all i can say is good luck

| ||

| Post# 503035 , Reply# 119 3/10/2011 at 16:55 (4,887 days old) by limey () | ||

|

Above Post Sorry folks above post, #503030 should have been in thread 33198. | ||

| Post# 504512 , Reply# 120 3/16/2011 at 12:16 (4,881 days old) by grahamW () | ||

|

A few final photos As requested via e-mail, here are some better photos of the seals.

| ||

| Post# 504514 , Reply# 121 3/16/2011 at 12:18 (4,881 days old) by grahamW () | ||

|

The inside of the large shaft seal which actually sits on the cast cradle. No metal in this one.

| ||

| Post# 504516 , Reply# 122 3/16/2011 at 12:21 (4,881 days old) by grahamW () | ||

|

The shaft seal that I needed to cut away to get a better grip on the inner bearing. This one does have metal in it. You can see the two lips of the seal but there is also a ridge at the edge that doesn't photograph very well.

| ||

| Post# 504541 , Reply# 124 3/16/2011 at 14:08 (4,881 days old) by pierreandreply4 (St-Bruno de montarville (province of quebec) canada) | ||

just a tough???? | ||

Post# 504669 , Reply# 125 3/16/2011 at 23:48 (4,881 days old) by sudsmaster  (SF Bay Area, California) (SF Bay Area, California) |

||

There are seals, and then there are seals...

Not on topic, but I just got through replacing the valve guide seals on the V8 motor in my vintage van. Wow, what a pain of a job that was. That the motor was still in the vehicle meant a lot of contortions to get at the various parts. And getting the right tools and tools that could fit into the tight spaces. Once I got the technique mastered (which too about four tries), things went more smoothly. 16 valves, with two seals per valve. At the end of the seal replacement I had to adjust the valves, hot, with the motor running. It was at that point that I realized why the motor had been running so poorly. The valves didn't have enough preload on the hydraulic adjusters, so they were barely opening. After I increased the preload to the ballpark where it should be, the van is running 100% better. And it doesn't stink at idle any more. Back to the topic: STPP will do wonders for preventing mineral buildup inside any washer. That's because it doesn't form scale when it encounters minerals - instead it surrounds them and keeps them in solution, so they can be rinsed away. Really is a miracle chemical. | ||

| Post# 504696 , Reply# 126 3/17/2011 at 05:15 (4,880 days old) by limey () | ||

|

A Note Of Thanks To all who have contributed to this thread, particularly Graham. Thank You. I have found it informative and enlightening. | ||

Post# 1047208 , Reply# 128 10/8/2019 at 21:33 (1,753 days old) by Launderess  (Quiet Please, There´s a Lady on Stage) (Quiet Please, There´s a Lady on Stage) |

||

Search archives

As one or maybe two members went through same or close situation and posted about their plight.

Bottom line is new parts from Miele Canada will dear, and IIRC certain bits only come as an assembly. Your other option is what many others do in such a situation, find another Miele washer from same model series/takes same parts, and swap things out. There are tons of DIY vids on Youtube regarding this matter: | ||

Post# 1047818 , Reply# 129 10/15/2019 at 22:58 (1,746 days old) by SudsMaster  (SF Bay Area, California) (SF Bay Area, California) |

||

Thanks to Bowsfixer and Laundrylady for resurrecting this zombie thread.

Why? Because I was trying to remember just when I adjusted the valve preload on my '67 Chevy Van. I guess I could always consult the service log I keep on all my vehicles, but ... there is my post up there, from 2011, telling the story. Yay.

More recently, I had cause to have to service the air cleaner housing on the van V8 motor. But that's another story.

And my advice about STPP still is good. The one thing that occurred to me now, if STPP is so good, why not add it to radiators? The reason is simple: STPP, for all its usefulness in a washer, is unstable, and would deteriorate into plain Sodium Phosphate rather rapidly in a hot radiator. It works just fine in a washer, where it spends itself latching onto hard water minerals and keeping them in solution so they can be flushed away. But in a car radiator the STPP would soon be inactivated and instead of preventing hard water mineral deposits, actually could form them.

It may help to think of STPP as a high energy chemical compound. It spends that energy by bonding to minerals and keeping in solution in a "complex". In storage, over time, STPP will release that energy and degrade into a simple, not complex, phosphate. We know this simple phosphate as TSP: Tri-sodium phosphate, which is often used to prep surfaces before painting. It's ok for cleaning walls before painting, because it won't stick to hard surfaces. But for fabrics etc it might cause a whitish residue which is the result of it bonding to hard water minerals and falling out of solution as a precipitate, which can look like lint on fabrics.

OK, enough of that.

PS-I actually have a Miele 1918 in my workshop, along with a couple of older 200F Mieles. I used the 1918 sparingly, mostly for whites. But I've got lazier for the past few years and have switched to using the Maytag Neptune for whites instead. Maybe one of these days I'll fire up the 1918 again, just for old times sake (and to get some stubborn stains out of white dish/hand towels that won't go away any other way, save chlorine bleach, which I refuse to use on fabrics).

| ||

Comes to the Rescue!

Comes to the Rescue!