|

Thread Number: 41284

My Hotpoint-Electra is now basically a Zanussi Jetsystem |

[Down to Last] |

| Post# 610233 7/14/2012 at 16:39 (4,303 days old) by optima (Cumbria England) | ||

| ||

|

| Post# 610236 , Reply# 1 7/14/2012 at 16:51 (4,303 days old) by optima (Cumbria England) | ||

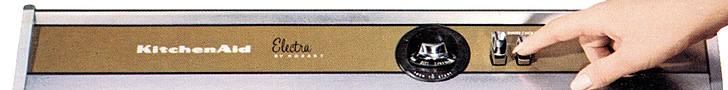

Electra | ||

| Post# 610238 , Reply# 2 7/14/2012 at 17:01 (4,303 days old) by optima (Cumbria England) | ||

Electra | ||

| Post# 610240 , Reply# 3 7/14/2012 at 17:08 (4,303 days old) by optima (Cumbria England) | ||

Electra | ||

| Post# 610247 , Reply# 4 7/14/2012 at 17:25 (4,303 days old) by optima (Cumbria England) | ||

Electra | ||

| Post# 610248 , Reply# 5 7/14/2012 at 17:30 (4,303 days old) by optima (Cumbria England) | ||

Electra | ||

| Post# 610250 , Reply# 6 7/14/2012 at 17:45 (4,303 days old) by optima (Cumbria England) | ||

Electra | ||

| Post# 610251 , Reply# 7 7/14/2012 at 18:04 (4,303 days old) by optima (Cumbria England) | ||

Electra | ||

| Post# 610254 , Reply# 8 7/14/2012 at 18:17 (4,303 days old) by optima (Cumbria England) | ||

Electra | ||

| Post# 610255 , Reply# 9 7/14/2012 at 18:27 (4,303 days old) by optima (Cumbria England) | ||

Electra | ||

| Post# 610300 , Reply# 10 7/15/2012 at 01:50 (4,302 days old) by qualin (Canada) | ||

|

Why don't more washer manufacturers do this? I think this is a great modification. | ||

| Post# 610320 , Reply# 11 7/15/2012 at 05:01 (4,302 days old) by nrones () | ||

|

Wonderful :) You did faaar better than me :P CLICK HERE TO GO TO nrones's LINK | ||

| Post# 610370 , Reply# 13 7/15/2012 at 12:38 (4,302 days old) by bertrum () | ||

|

Well done for making the modification. The Zanussi jet system machines have the jet system spraying through the door seal opening. Why not try adapting the current door seal to allow for the jet system, got to be easier than drilling holes in the drum?. | ||

| Post# 610371 , Reply# 14 7/15/2012 at 12:46 (4,302 days old) by dyson2drums (United Kingdom) | ||

Well done! :) Looks great, thank you for the video. I like how you have the option to turn it off using the rinse hold button. Must be fun to watch, I like the shower spray on my LG steam washing machine, don't know if it helps in the washing performance but it does help with dissolving the detergent quickly.

| ||

| Post# 610385 , Reply# 15 7/15/2012 at 15:34 (4,302 days old) by optima (Cumbria England) | ||

Electra

Thanks for your comments.

I did think about having it spraying out directly out through the top of the door seal, that would of been really great but i couldn't think of what i could possibly use as a jet & how to make it 100% water tight, i will try & think of other ways of doing it because it can be easily modified & as for the washing performance i don't think it makes that much of a difference but like you say it is fun to watch. The washing power is definitely used a lot better with zero percent wastage.

| ||

| Post# 610405 , Reply# 17 7/15/2012 at 16:47 (4,302 days old) by optima (Cumbria England) | ||

Electra

We used to have a Zanussi FJ1296 1200 spin machine that sprayed from the door seal & i can remember the model before it that looked & performed very much the same but that washer sprayed from the top of the drum. The one thing that i have noticed since i have modified this washer is that the washing is coming out of the machine feeling far better conditioned & with a lot less creasing.

| ||

| Post# 611421 , Reply# 20 7/21/2012 at 05:09 (4,296 days old) by aquarius1984 (Planet earth) | ||

Al

We had great success a couple of years ago fitting an 18 series pump to the WM64 replacing its noisy magnetic pump for a shaded pole version which is virtually super silent to run compared to its original. Mounting on rubber washers is a good idea IMO others may disagree but one thing is for sure the new 18 series pump will almost certainly need to be mounted by drilling new holes in the base of the machine as the original holes wont match up. Simple affair to achieve with a small drill bit. Fit pump to sump hose on machine and line up so the sump hose sits naturally then position pump in general area of old pump so sump hose is not kinked or obstructed and simply drill the new holes using the pump as a template. Next bit is the tricky part, you may need to remove or cut the machines pump connection wires and fit spade terminals which is just a simple case of going to Maplins and buying spades, thse are then crimped onto the wires and your good to go. Usually only 2 wires and it makes no odds which way round on the pump they go IIRC. 18 series pumps can usually be sourced on Fleapay for around £5 or so think we bought ours in bulk (10 for £30 IIRC) and have been brilliant. | ||

| Post# 611422 , Reply# 21 7/21/2012 at 05:33 (4,296 days old) by aquarius1984 (Planet earth) | ||

Criag great modification although I would be tempted to tune down the water level the machine uses so you get a really vigourous wash in really concentrated sudz.

As far as the door boot jet is concerned yes it gives more spray and splash action I wonder if a yellow "Fan" sprayer from a Zanussi Jetsystem could be used to make it watertight I daresay a small hole to fit it and jubillee clipped it would work. The hole you made in the outer tub at the top could be bunged with a rubber bung so you have the option of using both as your mood takes you. I would of suggested the green Hoover Quattro jet nozzle but they seem puny in comparison and the one on Mum's Quattro never did seem to do much to wet the load. Maybe the Earlier Candy Activa jet which sprays a fan of water could be an option too. That seemed effective but really does whip up sudz. Il have to say it though I could never do what you have done LOL Original IS best LOLOLOLOL...........

| ||

| Post# 611427 , Reply# 22 7/21/2012 at 07:09 (4,296 days old) by optima (Cumbria England) | ||

Rob

I'm more than happy really with the way it is now & i kind of like the suspense of watching it hoping that the drum will stop with the lifter towards the top filling it with water & showering it down on the load (which it does do very often) as for reducing the water level (great minds think alike) that is the next thing on my to do list. ps I want those lovely "classic Hotpoints" on show in my kitchen. | ||

| Post# 617023 , Reply# 23 8/14/2012 at 14:04 (4,272 days old) by HotpointFan (United Kingdom) | ||

Rob | ||

| Post# 623480 , Reply# 25 9/8/2012 at 19:59 (4,247 days old) by optima (Cumbria England) | ||

Well it's basically what i've done to my machine but with a lower wash water content & with the spin wash which is a total waste of time. The only one advantage of the Electrolux Jetsystem is that 100% of the detergent is being used when placed in the soap drawer, because the wash water is constantly pumped back onto the load. The thing i like about my machine is that it uses a lot more water to wash the clothes which gives a far better wash result.

| ||

| Post# 623529 , Reply# 26 9/9/2012 at 03:03 (4,246 days old) by newwave1 (Lincoln, United Kingdom) | ||

Rolls, you're Definately right about the heater in a separate chamber at the base of the machine.

I have a picture of one of those in one of my Haynes manuals. Not the case on the first split panel machines like the fj1033 like I had which went back to being in the drum. I love a good recirculatory jet. I think it is a great feature to have. Darren | ||

Comes to the Rescue!

Comes to the Rescue!