|

Thread Number: 41892

MOVING A MAYTAG E2L |

[Down to Last] |

|

| Post# 617295 , Reply# 1 8/15/2012 at 18:17 (4,363 days old) by qsd-dan (West) | ||

|

My concern is that if I lay it flat and travel 30 miles that way that oil from the transmission or wringer post might leak.

BTW, congrats! Hope pics will surface soon after its arrival. | ||

Post# 617340 , Reply# 3 8/15/2012 at 20:49 (4,363 days old) by Electronicontrl  (Grand Rapids, MI) (Grand Rapids, MI) |

||

|

Nice find

And for $25.00. Nice!

I agree, best to keep it upright. You can move the wringer control to the "swing" position and lift the wringer head up & off the base and that makes the machine easier to transport. (Careful the wringer head is HEAVY). I use my avocado Maytag E2LPS at least once a month. Congrats! and welcome! | ||

| Post# 617390 , Reply# 4 8/15/2012 at 22:19 (4,363 days old) by stan (Napa CA) | ||

Hi Larry

I'll third that up right moving idea. LOL

The raised MAYTAG on the front, I believe puts it somewhere after 1960? The vent hole, is on top of the right angle drive. (The part that's coming off the power unit, going towards left leg, where the wringer is) Sometimes it hard to see, but if you run your hand across the top, you'll feel it. Post pic's when you can! HTH, and welcome to the forum. | ||

Post# 617420 , Reply# 6 8/15/2012 at 23:43 (4,363 days old) by rp2813  (Sannazay) (Sannazay) |

||

Try Meguiar's Car Cleaner/Wax on the finish and see if you can revive it. You may not be able to reproduce the same durability of the original finish even with Rustoleum enamel.

You can hide scratches by using a small bottle of white appliance touch-up -- very sparingly -- the brush should have barely any product on it and you should apply by lightly dabbing just enough to obscure the scratch. Go slow. Less is more. Slather it on and it will be very obvious. I used this method on a vintage refrigerator and I can't even find the repaired areas anymore. Use the Meguiars after doing all of the touch-up work. It made the original enamel finish on my fridge shine like new. | ||

| Post# 617438 , Reply# 7 8/16/2012 at 02:02 (4,363 days old) by stan (Napa CA) | ||

Larry

Thats a very good question about the oil!! I have asked here before, and really never got a answer that I was comfortable with.

I have read on another thread here where someone claimed that he added spindle oil thru the side cover of the power unit while the machine was laying on it side?? However I have talked to Phil at Phils Maytag (someone many of us here have gotten parts and advice from) some years back and If I remember right, he said no? And I defiantly remember him saying that it could not be added thru the wringer post, and have it reach the power unit. I have a service manual for the machine, and I have studied it carefully, and can not see any way to add oil to the PU other than removing the PU from the tub, and adding gear lube directly to the to the top, and re bolting it back on. In that case it may require new seals ect if going that far! (now I think i want to get a hold of Phil and ask) LOL Think the MeGuire's is a good choice as well. MeGuire's also make a "fine cut cleaner" that will remove scratches and imperfections and then follow with the cleaner/wax that Ralph suggested. Since it's a E model, you may also have a little work to do to restore the brilliance to the aluminum tub, and crown. If so I would suggest you do that part first, then move on the the body, wheels ect. If I had mine to do over I think after getting the crown clean and polished, I would have sprayed a clear lacquer over it, then dealt with the body, as I'm always re polishing the crown from water spots. The E is a good machine for overnight soaking, as it holds the heat of the water for a long period of time. Glad to hear that the 52 lasted so long, they were great machines! Stan | ||

Post# 617465 , Reply# 8 8/16/2012 at 06:38 (4,362 days old) by maytagmike  (Burlington, Vt) (Burlington, Vt) |

||

my mom's maytag | ||

| Post# 617687 , Reply# 11 8/16/2012 at 22:19 (4,362 days old) by stan (Napa CA) | ||

Hi Geoff | ||

| Post# 618028 , Reply# 14 8/18/2012 at 01:30 (4,361 days old) by stan (Napa CA) | ||

Thanks Geoff

for the info!

Yes I do plan in keeping the machine, and as of now it is the daily driver for the household laundry. I believe, or I hope it's the the "first" of the two things you mentioned LOL Im assuming the oil in the power unit is 90 weight gear oil, and the right angle and wringer post is packed with something like wheel bearing grease? ? As I mentioned this only happens on occasion (oil Leak) from that location, and is usually about the size of a nickel, on the floor, with a little more that gets caught on the cross frame, from where it actually drips off of. The machine seems to run fine otherwise! Do you think it's time to take it seriously ? Stan | ||

Post# 618047 , Reply# 15 8/18/2012 at 03:33 (4,361 days old) by rp2813  (Sannazay) (Sannazay) |

||

PDF file for only $1.99 | ||

| Post# 618061 , Reply# 16 8/18/2012 at 09:12 (4,360 days old) by laundromat (Hilo, Hawaii) | ||

That looks like the one I was just given to by a friend here in Rosedale. We were in "comformation" at Church and classmates in school. His Dad replaced an older model with a newer the last of which were made around 1972. She used it three times and hated it so it has been covered with plastic in a corner all by its lonesome until I found it and was happily told I could have it. I need to get the weight so I can have it shipped to Hawaii.It is my favorite style of single tub wringer washers.

| ||

| Post# 618193 , Reply# 19 8/18/2012 at 21:36 (4,360 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

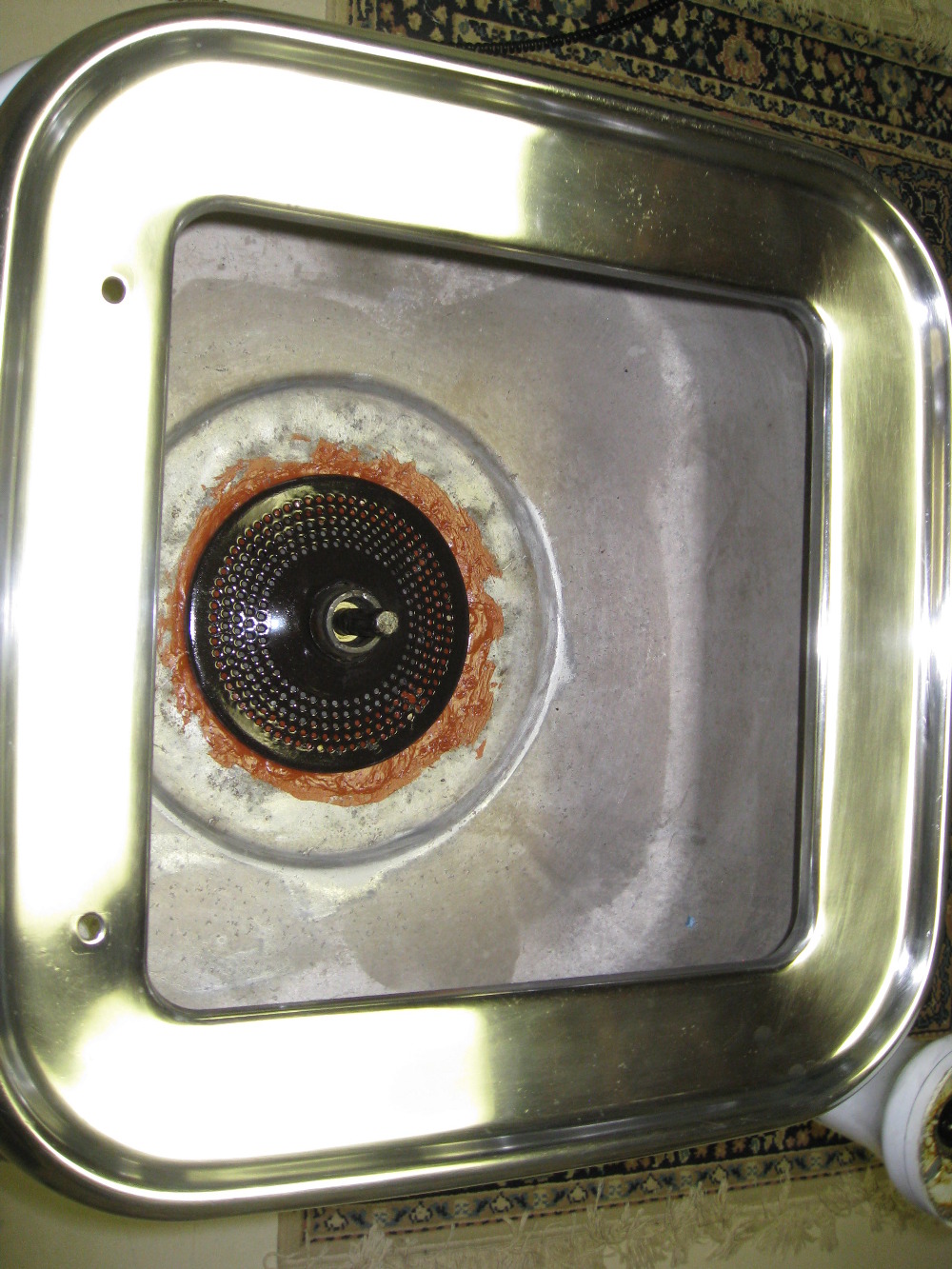

GASKETS I just found a gasket kit for Maytag wringer washers. On Ebay it said it was for "vintage 80's Maytag Wringer Washers. I think mine is a 60's version but it's that same isn't it? Her a picture of my broken agitator.

| ||

| Post# 618271 , Reply# 20 8/19/2012 at 02:02 (4,360 days old) by stan (Napa CA) | ||

Hi Larry

I was hoping that you were going to be able to fill and go, but no such luck! Damm!

Rest assured we are here to help in our own way! Geoff will probably be along and will have very good tips for you. Until then...the gaskets are the same (60's to 80's) You might as well do the best you can to remove the agitator, and see what kind of bolts are under, that hold the PU on, if they are the gulmite bolts, you'll have to start looking for a gulmite wrench. Think it's impossible to get the WD 40 to reach the spot it would need to, with agitator still on, unless you can squirt it down the the broken spot and have it reach? (wishful thinking) It may require laying a 2 by 6 by 3 ft board across the top of the machine, and using a couple of strong straps slid under two sides of the agitator, brought up over the board and over a steering wheel puller, or small floor jack rigged up to lift the agitator straight up off the post. Once the agitator is off, you could try another water test to make sure removing the PU is necessary. Sometimes it's just one bolt that water seeps thru, and makes it look worse from underneath than it really is ( again this is total wishful thinking, but no harm in trying at this point) LOL. Have you plugged the machine in without water to make sure the electric motor is working? Also from the pics, it looks as though the machine is gravity drain only?? Sounds like the cosmetics will have to come later, you have a little work to do first. Keep us posted! pics Stan | ||

| Post# 618355 , Reply# 23 8/19/2012 at 12:32 (4,359 days old) by stan (Napa CA) | ||

Hi Larry

The top half should go back on easy, just turn the tension bar back and forth as your trying to drop it in, and you'll figure it out!

Another common problem with these machines is the "index slide" in the wringer. This is the part that locks the wringer into position when you are putting clothes thru. Many time this is broken from someone manhandling it! (very easy fix with new part) | ||

| Post# 618523 , Reply# 25 8/19/2012 at 23:45 (4,359 days old) by stan (Napa CA) | ||

Hi Larry

Don't give up yet!

You might want to Google around a bit, and find a some aluminum patching, probably a fiberglass resin, and cloth kit found in a auto supply will work, since it's not going to show, like a fender on a car, it dose'nt have to be perfect, just water tight, they also make patching for aluminum boats that should work! If it were me I'd try to patch, then check to see if tub holds water, if so, then go a head and remove what's stuck to the post. if it is leaking badly into the PU, you'll know quick enough, as water and oil will start to come out of the weep hole as mentioned up thread. Looks like it will take a little time and elbow grease to get that loose from the post, but you'll get it! If you get that far, you can start to clean the tub with hot water,and a S.OS pad with light pressure, then hot water and detergent, and 2000 grit sandpaper, to bring back some shine. Same for the crown! (you'll rinse a lot of dark grey water away, but thats normal) Now if you actually get THAT far, the I would spray some clear lacquer on just the crown (masking everything else off) as I wish I had done with mine! As best as I can see, it looks like you have the gulmite bolt on yours? Hopefully you won't have to mess with them! Hang in there Larry! If you get flustered, walk away for a while, it aint going anywhere. Take your time HTH Stan | ||

| Post# 618548 , Reply# 26 8/20/2012 at 03:23 (4,359 days old) by stan (Napa CA) | ||

The more I look

at that last photo. they more I feel that there is nothing leaking into that PU? Just call it a hunch!

If those holes can be patched, and if you can get something under that left over agitator spine, to lift it off (blow torch heat gun may help) I think you'll be O.K! I have lots of ideas of how to make the machine look new, but you got to get past this first! Forgot to ask if you found the lint screen (sediment trap) under the agitator? I have a service manual for this machine in a PDF I think? for sure I have it on a disk. Let me know if I can help you with that at least. Stan | ||

| Post# 618549 , Reply# 27 8/20/2012 at 03:39 (4,359 days old) by qsd-dan (West) | ||

|

I fully agree with what Stan says above. He provided great advice.

You may be able to patch smaller holes with JB Weld. Once all of the holes are patched up, coat the rest of the rust with something like POR-15 which will encapsulate and prevent any further rusting.

You'll need to chisel the drive block off of the agitator shaft. That's supposed to remain inside the agitator. You new agitator will come with a plastic one already installed inside of it.

Don't give up yet! She's still got plenty of life and many loads left in her.

| ||

| Post# 618696 , Reply# 28 8/20/2012 at 15:50 (4,358 days old) by stan (Napa CA) | ||

Rust

is the oxidation of iron!

So IMHO Im not sure about the Por 15 for this application? But I've never used Por 15 either so maybe? Remember what ever it's patched with, has to stand up to hot water and detergent (why I think a boat patch 'maybe" is best) Aluminum, will oxidize in a short period of time... reason why I suggested cleaning and polishing the crown, and spraying with the clear lacquer (to stop oxidation) just for cosmetic reasons. The holes are caused by corrosion (not rust) most likely from modern detergents that are heavily dosed with Washing soda (a corrosive to aluminum) Chlorine Bleach (also corrosive) and obvious neglect (someone never removing the agitator, rinsing, and properly draining out, and wiping the machine dry) You can kind of tell from their location (lowest point where water would set the longest) Keep us up to date Larry | ||

| Post# 618826 , Reply# 30 8/20/2012 at 22:47 (4,358 days old) by stan (Napa CA) | ||

hi Larry

It's really not complicated at all

but to tell you the truth I would avoid going there unless you have to! Think of it like "your the Doctor and it's the patient" First do no harm LOL For what it's worth... It just dose'nt make sense to me that you have to "assume" that water has gotten into the PU without hard evidence! Since the motor works and there is still a belt turning the agitator, why not run the machine, (motor and belt) for an hour or so. (cant hold water now anyway) and see if anything leaks out of the weep hole, and listen to how the gears sound. If it sounds O.K and there is no seepage, then lets "assume" that water has NOT gotten into it! If your prepared to do a tare down now, then you'll be prepared later. Do you see my point? If it were me, I'd go ahead and get a new agitator, your going to have to anyway if your going to restore it later! (and keep it a washing machine) In the mean time, patch the holes to make sure the tub holds water. Then run the machine and see! There is nothing lost at this point. If evidence shows up later, that water IS getting in, then you still have'nt lost anything, because you were ready to do a tare down in the first place. Even if water has gotten into the PU, it still may not be necessary to "rebuild" it, more like cleaning and refilling with the correct gear oil. (if you could see inside, you'd see what I mean. Not much to go wrong in there) I'll try to email you a PDF file of the service manual. (if you want) If that dose not work then I'll be in touch to snail mail it to you on a disk. I understand that having a pump on it may not bother you now, because of the floor drain you have, but you should know, if you don't already, that one can be added in the future without a lot of effort. Phil has them. I think for about $45.00 Sure wish this had gone a little easier for you, but they are fun little projects! Let me know Stan | ||

| Post# 618830 , Reply# 32 8/20/2012 at 23:05 (4,358 days old) by stan (Napa CA) | ||

Oil | ||

| Post# 620968 , Reply# 35 8/28/2012 at 23:09 (4,350 days old) by stan (Napa CA) | ||

thanks Larry | ||

| Post# 621149 , Reply# 37 8/29/2012 at 18:41 (4,349 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

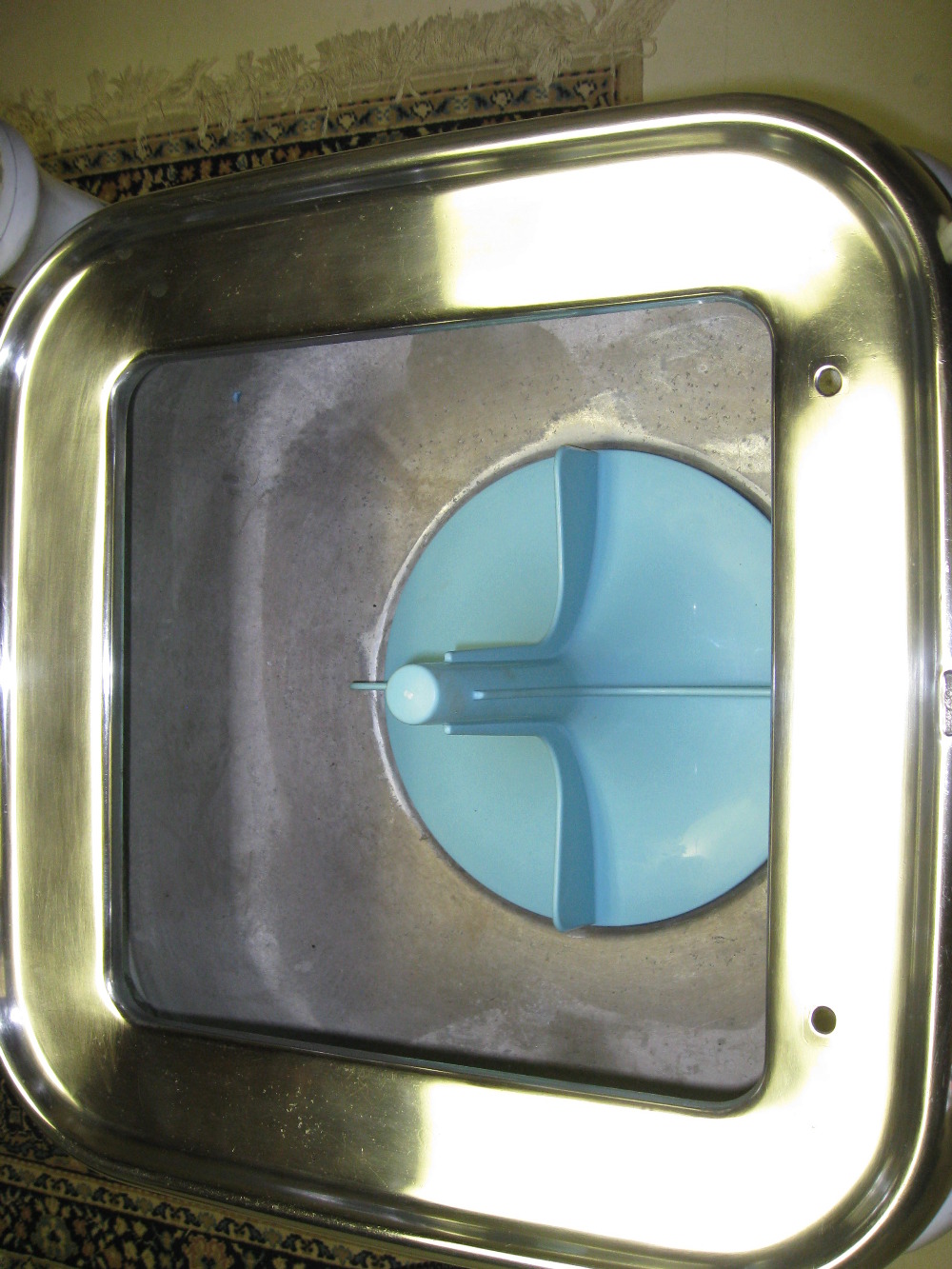

With drain filter Now with the newly painted drain filter. It covers some of the patchwork and the agitator will cover it all. I thought only pump models came with the screen but mine had one?

| ||

| Post# 621150 , Reply# 38 8/29/2012 at 18:43 (4,349 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

The finish Here with the new agitator. I used Mother's Mag & Aluminum Polish on the crown. I found it at the Auto Parts store. Make it shine mike a baby's forehead!

| ||

| Post# 621151 , Reply# 39 8/29/2012 at 18:46 (4,349 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

Next! On to the wringer! The sealant will be ready Thursday and I ordered a new center plate agitator seal. If that shows up by Friday I hope to have a water test this weekend. Once I get there I'll tackle getting the tub back into shape.

| ||

| Post# 621226 , Reply# 40 8/30/2012 at 00:15 (4,349 days old) by stan (Napa CA) | ||

all looks  | ||

| Post# 621238 , Reply# 41 8/30/2012 at 02:16 (4,349 days old) by qsd-dan (West) | ||

|

| ||

| Post# 621391 , Reply# 43 8/30/2012 at 17:43 (4,348 days old) by mickeyd (Hamburg NY) | ||

The crown is out of sight beautiful | ||

| Post# 622404 , Reply# 46 9/3/2012 at 19:40 (4,344 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

The tub Here's the tub after some clean up and polishing.

| ||

| Post# 622405 , Reply# 47 9/3/2012 at 19:41 (4,344 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

My E2l as on 09/03/12 Coming along!

| ||

| Post# 622420 , Reply# 48 9/3/2012 at 20:40 (4,344 days old) by mickeyd (Hamburg NY) | ||

Can't believe how beautiful she is  | ||

| Post# 622618 , Reply# 49 9/4/2012 at 19:58 (4,343 days old) by stan (Napa CA) | ||

Release bar | ||

| Post# 622883 , Reply# 51 9/5/2012 at 22:58 (4,342 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

Sanded and Primed the washer itself, or do they call that the skirt? tonight. A coat of paint over the weekend. Wait 3 days and apply the finishing coat and I've got myself a pretty sweet Maytag EL2 conventional washer!

| ||

| Post# 623312 , Reply# 52 9/7/2012 at 22:27 (4,340 days old) by stan (Napa CA) | ||

Larry  | ||

| Post# 623342 , Reply# 53 9/8/2012 at 02:01 (4,340 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

The floor drain is next to the water heater, Page 47, a few frames up shows it with the hose in the floor drain. It works OK but I think you're right. Once the smoke clears, I'd like to add a pump. | ||

| Post# 624577 , Reply# 55 9/12/2012 at 23:41 (4,335 days old) by stan (Napa CA) | ||

since you have the laundry sink | ||

| Post# 624771 , Reply# 57 9/13/2012 at 21:22 (4,334 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

Today 09/13/12 I tried to stage it as the first picture I posted last month. Sort of a before/after thing.

| ||

| Post# 624862 , Reply# 58 9/14/2012 at 09:53 (4,333 days old) by wringer (x) | ||

|

WOW !! You did a beautiful job!!! Don't forget to keep the wringer rolls separated so they won't stick together. You are entitled to be very proud of your work and all of the effort you put into her that others would not have done. Enjoy !! Jim | ||

| Post# 624956 , Reply# 59 9/14/2012 at 16:18 (4,333 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

Thanks Jim! I do usually keep the wringer open when not in use. This was a staged picture to pose it as the first pic i took when I got it home and the wringer was broken so it was closed. Here's another picture with it open as usual.

| ||

| Post# 624984 , Reply# 60 9/14/2012 at 18:09 (4,333 days old) by mickeyd (Hamburg NY) | ||

About the hose issue

The alumium hook might srew on, if your hose end is threaded, but it would be at an angle. The pump is so much fun, but the original hose is tight and short. I replaced mine with a longer, more pliable one. Guessing you'd only want the real deal.

It's almost mind-boggling what you've done. She looks like she just walked off the Newton runway. Congrats! | ||

| Post# 625070 , Reply# 63 9/15/2012 at 01:18 (4,333 days old) by bradross (New Westminster, BC., Canada) | ||

Amazing job, Larry!

Larry, I've been so pre-occupied with the restoration of my Model 30 that I haven't kept up - until now - on the AMAZING restoration of your model E2L! You have truly put some luvin' into it - along with a LOT of hard work (as I can attest!) Wish I had more room than just an apartment to do restoration work - the painting is my real challenge, plus not having things like a work bench, vice, etc. Some day hopefully I'll have more room - would be fun to do these restorations on a regular basis. Plus more room to add to the collection!

Once again - kudos on the magnificent restoration work! Now have fun using it, as I do mine! | ||

| Post# 625172 , Reply# 64 9/15/2012 at 13:00 (4,332 days old) by mickeyd (Hamburg NY) | ||

Larry There is a handful of us from Western New York, and yes, Hamburg is the next big thing west of Buffalo while Kenmore is the next big thing east of it. I'm just ten minutes from downtown on Lakeshore road, and Kemmore is another 15-20 minutes out Delaware Avenue, less on the Expressways. Small world. How cool.

For me, half the fun of the Maytag Conventional is the pump, and while I don't like the hose, the pump itself is right out of this world, a great deep rumble, very fast, and very big. You will be amazed at how quickly it flushes 18 gallons of water back into the ocean ;+> This post was last edited 09/15/2012 at 16:29 | ||

| Post# 625248 , Reply# 67 9/15/2012 at 20:11 (4,332 days old) by bradross (New Westminster, BC., Canada) | ||

Patching the tub ...

Larry, I initially used J-B Weld in the tubes (epoxy), which hardens terrifically, but is hard to put on smoothly and difficult to sand. So...I changed to the J-B Weld "Steel Stik", which is a putty and quite easy to work with. You have just a couple of minutes to put it into place and smooth it out before it hardens "like steel"! I sanded it quite smooth and it's totally leak free. My crack was on the top edge of the sediment trap, so rather visible, and therefore wanted a product that would match the metal, which the SteelStik does beautifully.

The green paint is a color called "Leaf Rising" by Valspar from Lowe's. Not sure of its durability - it takes several days to really get hard. I've already put a small scratch on the lid - but no big deal, I'll just touch it up. Regarding the decals, I've been in touch with Kevin Fisher, the "decalguy" in Ohio. I'm going to order them from him in the near future. P.S. Glad you've been enjoying the vids - I've done 8 in total. | ||

| Post# 625400 , Reply# 68 9/16/2012 at 12:31 (4,331 days old) by mickeyd (Hamburg NY) | ||

Your work is so exceptional that I keep forgetting you're brand new here. That means you probably do NOT have an easy dozen or more drain hoses hanging around the basement and the garage. Many here do. Almost any hose will fit the white steel port--3/4 or an inch, I forget--with a nice banded clamp with the screw. This one sports a five buck hose from True Value.

I was underneath the E2LP yesterday and realized that it is the big fly wheel that left such a strong memory of super-sized. I think you will really enjoy the pump. If using the machine for rinsing, and have a particularly sudsy load, you can get an underflow rinse going: high pressure inlet of fresh water with the pump on. Lots O' fun. Would you reveal your trade/occupation/ career or hobby that has afforded such skill?

| ||

| Post# 625411 , Reply# 70 9/16/2012 at 13:27 (4,331 days old) by mickeyd (Hamburg NY) | ||

Jim

We've never had a confessional thread about what it's really like to be a washer man, but I'm in and out of the "Washer Parts" aisle of every big box, hardware, appliance, and plumbing store in town. This item came with a straight gray hose, and the space-age hook. I CAN'T remember which venue had it, it's a few years old, less than 5, but I'll see if it's still stocked in my usual spots during the next few bike rides. Five bucks.

In the garden section at Walmart you can get a few cool new fixtures to attach to the garden hose, one has a long arm with an adjustable spray pattern. Ironic, that whichever spray pattern you select, it is distinctly similar to any one of the spray rinses in all the various automatics. The "Maytag" one is especially recognizable. Just go mosey around and see what's out there when you're free and don't have to shop for a whole bunch of stuff; you'll "get it" right away. Also, if you have any elbows or faucets hanging around, see if any can be retrofitted onto your hose. You can rig a lot of stuff, once you let your imagination fly. Don't laugh, but you just gave me a new idea for outdoor washing-- a really cool lawn sprinkler attached to a Plexiglas lid for one of the wringer washers. What a fill that would be! Of course, the agitator would have to be in motion, and the sprinkler upside-down, naturally.

This post was last edited 09/16/2012 at 14:29 | ||

| Post# 625465 , Reply# 72 9/16/2012 at 16:28 (4,331 days old) by bradross (New Westminster, BC., Canada) | ||

Larry - motor seizing and humming...

Hello again, Larry ... the old motor in my Model 30 does that sometimes as well, when I initially plug it in. At first, I panicked also, but then discovered if I just wiggled the pulley or belt a little, the motor runs just fine. Maybe it's a lubrication issue. I've never had that happen on my Model E2LP, but then, it is in VERY good shape, and is a 1977 model - not a 1933, like the 30.

| ||

| Post# 625574 , Reply# 74 9/17/2012 at 04:38 (4,331 days old) by stan (Napa CA) | ||

Hi Larry  | ||

| Post# 625674 , Reply# 77 9/17/2012 at 14:11 (4,330 days old) by stan (Napa CA) | ||

Hi Geoff | ||

| Post# 625712 , Reply# 79 9/17/2012 at 18:08 (4,330 days old) by mickeyd (Hamburg NY) | ||

Geoff to the rescue The giant fly wheel must be the reason behind the pump's superiority to the other wringer's I've used: Norge, Speed Queen, and Kemore. Wondering what the Easy pump is like on their wringers.

Scratching my head when you guys had me under her skirt the other day and seeing that the pump was not remarkable in size, while the fly wheel seemed huge. Why does it drain so fast and sound so powerful? It's the fly wheel.

| ||

| Post# 625738 , Reply# 81 9/17/2012 at 19:52 (4,330 days old) by qsd-dan (West) | ||

|

I wonder if it's a lubrication problem?

On earlier model units, the original motors had 2 oiling ports at each end of the shaft and could be oiled without removing the motor. Later model motors needed to be completely disassembled in order to oil them. IIRC, Maytag recommended a dealer to disassemble and oil the motor every 5 years for these style motors. I purchased an older model motor with oil ports on Ebay last year to replace the original newer style motor that's currently in my E2LPS. This will allow me to periodically (over) oil the motor without having to remove it. It'll get fully disassembled, cleaned, shimmed, oiled, and assembled before I swap it in. | ||

| Post# 625752 , Reply# 82 9/17/2012 at 20:25 (4,330 days old) by stan (Napa CA) | ||

Larry

if your going to pull that baby out, I'd try what Dan suggested first.

Again, nothing lost by trying the least path of resistance! Once your in (disassembled) you may spot the problem yourself, and "fingers crossed" it be something simple, Still feel your doing it a world of good just running it, and getting things moving! Thanks Geoff for the info! I plug mine into a power strip and turn on and off the the switch there, instead of plugging, and un plugging from this 100 year old outlet! LOL. But glad to know it's possible, and that there may be a third neutral screw. | ||

| Post# 625762 , Reply# 84 9/17/2012 at 21:19 (4,330 days old) by qsd-dan (West) | ||

|

so maybe a few drops of 3 in 1? | ||

| Post# 625771 , Reply# 85 9/17/2012 at 21:37 (4,330 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

UH OH, I already used the red one. What's the difference? | ||

| Post# 625773 , Reply# 86 9/17/2012 at 21:50 (4,330 days old) by qsd-dan (West) | ||

|

Blue Can = 20 weight turbine oil that lacks detergents, paraffins, and naptha.

Red Can = 10 weight oil that contains detergents and paraffins. It also contains naptha which gets dirt into suspension, then evaporates and leaves dirt on the bearing surface. Dirt being ground into the bearing while operating will quickly wear out the bearings. | ||

| Post# 625788 , Reply# 88 9/17/2012 at 22:58 (4,330 days old) by qsd-dan (West) | ||

|

It'll probably be ok. You may want to pick up a blue 3 in 1 bottle and squirt some turbine oil in the ports to dilute the other oil. It's also the proper lubricant to use.

Most people way back when used anything that remotely resembled oil in these applications, especially vintage fans with oil ports. Those fans are still running decades later, so you should be fine. | ||

| Post# 626034 , Reply# 93 9/19/2012 at 00:19 (4,329 days old) by stan (Napa CA) | ||

I'm soo

butt hurt! LOL

after all Larrys work you'd think he would have been rewarded with a working machine! I guess no good deed... Damn it! Think we should all admire his tenacity on this! I'd have pushed the SOB into the river, if I'd gone to this trouble. (but I digress) Chin up dude, we are with you, keep going! | ||

| Post# 626097 , Reply# 96 9/19/2012 at 10:50 (4,328 days old) by mickeyd (Hamburg NY) | ||

HI Jim I'll get on it right away today, or first thing in the morning, LOL.

Glad you found it. There's always a way to rig automatic, valve-like filling on a conventional, YAY !

LARRY: If I'm reading right, your motor stalling has stopped. So it's all good, I presume. My Norge did the same thing 4 or 5 times at the beginning of summer after a year and a half of hibernation, but now it's fine and hasn't stalled since the end of June. Her skirt goes to the floor, so I had to lay her down to get at the belt, which was a real pain in the banana, but I kept at it, patiently attending to her demands, and she finally healed. This post was last edited 09/19/2012 at 11:57 | ||

| Post# 626216 , Reply# 99 9/20/2012 at 00:24 (4,328 days old) by stan (Napa CA) | ||

Larry

I was just so disappointed for you, guess I got too emotional! LOL

I'm near a river... so ... my first thought was... I'll be curious to know what you find too! Maybe only needs oil?? What kinds of sounds did you hear coming from the P.U before this happened? Think Jim may be on to something with the dremel idea! You have the gulmite wrench don't you? | ||

| Post# 626321 , Reply# 102 9/20/2012 at 11:43 (4,327 days old) by geoffdelp (SAUK RAPIDS) | ||

|

Don't forget about Lehman's Hardware in Kidron, Ohio! Ask for the Service Department; they sell lots of parts for reconditioning Model E's. CLICK HERE TO GO TO geoffdelp's LINK | ||

| Post# 626343 , Reply# 104 9/20/2012 at 13:14 (4,327 days old) by mickeyd (Hamburg NY) | ||

Agreed, projects are fun, | ||

| Post# 626612 , Reply# 107 9/21/2012 at 17:02 (4,326 days old) by qsd-dan (West) | ||

|

I figure I can just use 90 wt. gear oil from the Auto Parts

Best to get and use the real deal. 6-0560800. Use 12 ounces from the 34 ounce bottle.

Shop around and find the best deal. CLICK HERE TO GO TO qsd-dan's LINK | ||

| Post# 626627 , Reply# 108 9/21/2012 at 17:29 (4,326 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

AMAZON! Who'd have thunk it! I ordered it on my account. Thanks Dan! I ordered my stuff from Phil today too. Soon it will all come together and I can finish out this project. Than, as the 3 Stooges say, "There will be nothing to do but live off the fat of the land . . . And eat and sleep!" | ||

| Post# 626677 , Reply# 110 9/21/2012 at 21:44 (4,326 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

ANOTHER CLUE Serious oil down the wringer leg.

| ||

| Post# 626681 , Reply# 111 9/21/2012 at 22:05 (4,326 days old) by stan (Napa CA) | ||

where in the hell  | ||

| Post# 626683 , Reply# 113 9/21/2012 at 22:19 (4,326 days old) by qsd-dan (West) | ||

|

Son-of-a.... | ||

| Post# 626686 , Reply# 115 9/21/2012 at 22:30 (4,326 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

Beyond difficult, is an understatement! Luckily, after I get the new tub and open up the PU, there's really nothing else to go bad. Then Like Geoff says, it will run for years and years. | ||

| Post# 626691 , Reply# 116 9/21/2012 at 23:16 (4,326 days old) by qsd-dan (West) | ||

|

| ||

| Post# 626695 , Reply# 117 9/22/2012 at 00:12 (4,326 days old) by stan (Napa CA) | ||

Larry

are you able to tell if this oil leak actually has water in it?

My E has done something similar once (not that bad) after I had added gear lube down the wringer post. I had had the machine on its belly replacing the belt, and " thought" after that I should add a little for good measure. But she didn't like it and spit it out later! (what I put in came down that leg) A couple of times thru the years, I have had some very thick grease, about the size of a nickel (grey brown) ooze out of the weep hole, but never noticed water in it. If I remember right, think it was on some hot days, that this happened ? A few here have said that it's not uncommon for these old girls to leak a little. Maybe it WAS a old lady fart (air) or something ?? I'll be interested in what Geoff has to say about this. | ||

| Post# 626794 , Reply# 123 9/22/2012 at 12:46 (4,325 days old) by mickeyd (Hamburg NY) | ||

"... this Mr. Haney (Green Acres) washing machine! " Look out for Mr. Haney coming over with another one of his famous, unbreakable, never-before-seen, lifetime " GAR UUNNN TEED" E2L's . LOL

You gave me a nice chucke. All along I've wanted to say, there have been so many of these in better condition offered for sale......., but ya never know till you get it home, anyway, so who knows? And you seem to have found a great hobby. Hey, maybe when you retire, you could be the E2L --L for Larry's --Restoration Company. | ||

| Post# 626889 , Reply# 129 9/22/2012 at 19:17 (4,325 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

NEXT I was able to remove the tub. Just like Geoff said, kind of moved from side to side and rotated around until it was out. Not too bad at all!

| ||

| Post# 627141 , Reply# 135 9/23/2012 at 19:03 (4,324 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

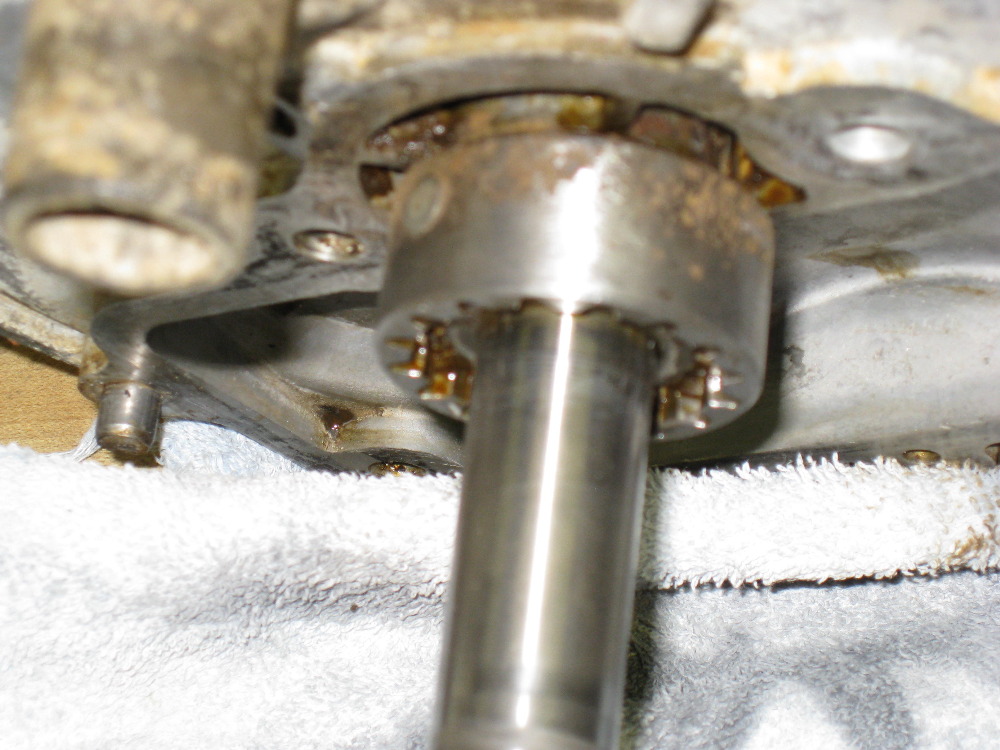

This is the underside of the center plate. I little corrosion on the collar. I wet sanded it with some WD-40. I don't think it will affect performance but I've been wrong before. It's true!

| ||

| Post# 627149 , Reply# 139 9/23/2012 at 19:33 (4,324 days old) by stan (Napa CA) | ||

I see it! | ||

| Post# 627155 , Reply# 140 9/23/2012 at 19:47 (4,324 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

EVERYTHING MOVES freely. I'm just wondering about the worm wheel. It' not missing the complete tooth. Just a bit of one is broken off on the end facing the inside of the P.U. I don't think that what was on the shaft though. Completely different size and shape. | ||

| Post# 627167 , Reply# 141 9/23/2012 at 20:24 (4,324 days old) by stan (Napa CA) | ||

Humm  | ||

| Post# 627173 , Reply# 142 9/23/2012 at 20:38 (4,324 days old) by mickeyd (Hamburg NY) | ||

And about the mysterious fly wheel | ||

| Post# 627176 , Reply# 144 9/23/2012 at 20:59 (4,324 days old) by stan (Napa CA) | ||

Good question!  | ||

| Post# 627210 , Reply# 147 9/23/2012 at 23:34 (4,324 days old) by stan (Napa CA) | ||

so... | ||

| Post# 627306 , Reply# 150 9/24/2012 at 13:25 (4,323 days old) by mickeyd (Hamburg NY) | ||

Laughing pretty hard right now about the farts, etc. | ||

| Post# 627373 , Reply# 153 9/24/2012 at 19:47 (4,323 days old) by stan (Napa CA) | ||

Farts

"it must have had some air/water/oil bubble in the right angle drive"

like I said up thread "these are old ladies, they just do that" can't be helped ! waiting to see if what you find Larry, if nothing, than it had to be that loose piece of metal that hung up in there! I'm curious to see what the new gaskets/seals are going to look like when you get them! Also curious about the right angle drive re packing. | ||

| Post# 627391 , Reply# 156 9/24/2012 at 21:19 (4,323 days old) by geoffdelp (SAUK RAPIDS) | ||

|

Stan you're funny. Poor old lady ... she just had to get that stuff out of her! Larry to the rescue!! :-) | ||

| Post# 627408 , Reply# 158 9/24/2012 at 22:13 (4,323 days old) by stan (Napa CA) | ||

Larry  | ||

| Post# 627409 , Reply# 159 9/24/2012 at 22:14 (4,323 days old) by mickeyd (Hamburg NY) | ||

" think about washing clothes AND wringing all at once;  not to mention....Pumping. It's really fun to have all three functions going simultaneously. The low percussive rumble always reminds me of a hydroelectric damn which is kind of funny since I've never been up close and personal to one. Must be a movie memory.

Love seeing the wringer deconstructed and that oozy worm gear looks almost alive. | ||

| Post# 627576 , Reply# 162 9/25/2012 at 21:33 (4,322 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

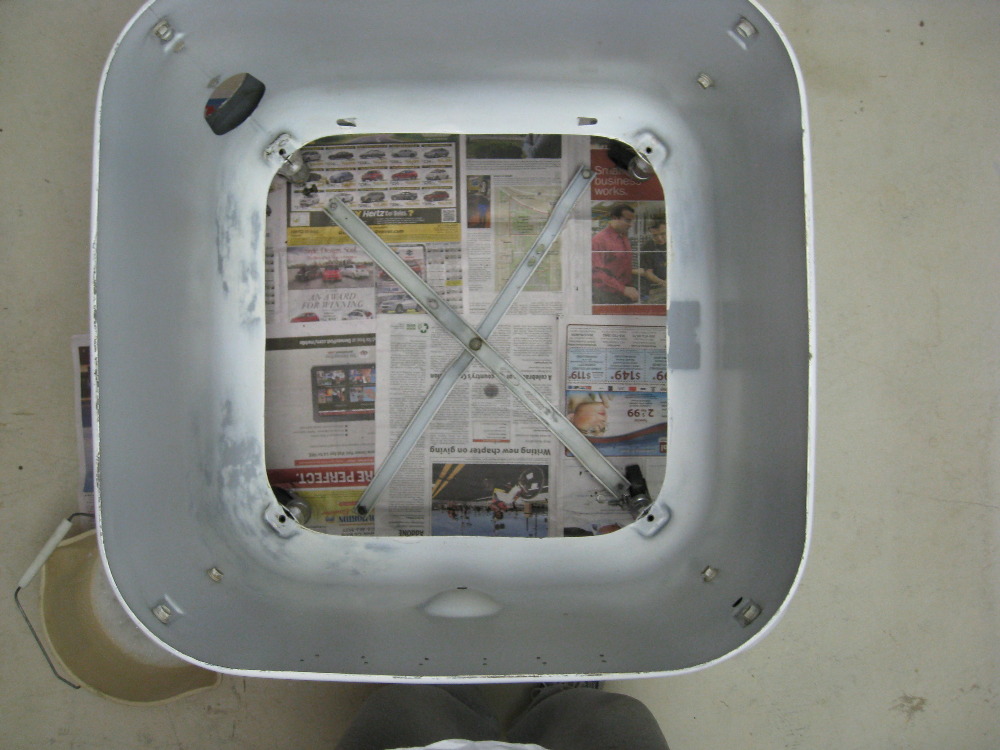

Today I cleaned and prepped for painting the inside of the tub (do I see where the pump "on off" lever went?) It took a bit of elbow grease to remove all that transmission grease. Tomorrow night I paint the inside of the tub.

| ||

| Post# 627579 , Reply# 165 9/25/2012 at 21:50 (4,322 days old) by geoffdelp (SAUK RAPIDS) | ||

|

Rustoleum (or something like it) on that right angle drive; you'll like the results. Let us know what kind of grease you get for packing that wringer post. | ||

| Post# 627589 , Reply# 166 9/25/2012 at 22:58 (4,322 days old) by stan (Napa CA) | ||

synthetic grease?

Dose Phil mean the wheel bearing grease? And did he say how much to put in?

The weep hole looks bigger than I expected. Have never really got a good look at mine (just felt it) Larry what dose that right angle drive look like from the other end, looking inside? (the end that bolts to the P.U) We talked about the letters on the front, now that the tub is out how did Maytag fasten them (speed nut ?) Or do they just fit in tight (small hole) push in pull out? Don't you boys think that when Larryss done, that his pics need to go into "restorations" Have email Robert to ask how one qualifies, but haven't heard back yet. Anyone know? | ||

| Post# 627595 , Reply# 169 9/25/2012 at 23:29 (4,322 days old) by stan (Napa CA) | ||

You know | ||

| Post# 627769 , Reply# 172 9/26/2012 at 19:27 (4,321 days old) by stan (Napa CA) | ||

Well I'll be  | ||

| Post# 627802 , Reply# 177 9/26/2012 at 21:05 (4,321 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

I painted around the letters A trick I learned. I cover the letters with Vaseline. Then carefully paint around them. Then if I get any paint on the letters it wipes off with the Vaseline. Works Great! | ||

| Post# 627887 , Reply# 178 9/27/2012 at 10:06 (4,320 days old) by wringer (x) | ||

|

What a trick !!!! I will have to tell the Amish about this if it is OK with you. I will call them today about the tub. Will let you know when I hear from them. Jim | ||

| Post# 627953 , Reply# 180 9/27/2012 at 18:08 (4,320 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

OK Got the horizontal drive painted. And got the lower part of the vertical 100% Bosco Free!

| ||

| Post# 627954 , Reply# 181 9/27/2012 at 18:12 (4,320 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

PAINTED THE INSIDE Of the skirt last night. Could use a second coat maybe but guess what? AIN'T gonna happen! It's the INSIDE for cryin' out load! Where over 1/2 is covered with the tub. Still as good or better that the day it came off the line.

| ||

| Post# 627969 , Reply# 183 9/27/2012 at 18:57 (4,320 days old) by stan (Napa CA) | ||

Yah | ||

| Post# 628195 , Reply# 188 9/28/2012 at 21:33 (4,319 days old) by stan (Napa CA) | ||

Good question!  | ||

| Post# 628204 , Reply# 191 9/28/2012 at 22:27 (4,319 days old) by wringer (x) | ||

|

The gasket you need that Geoff mentions looks like a huge o ring Larry. I think, but am not sure that the old cast heavy tubs used the cork gasket. Geoff may have to correct me on that one. Jim | ||

| Post# 628407 , Reply# 195 9/29/2012 at 22:30 (4,318 days old) by stan (Napa CA) | ||

Smart move | ||

| Post# 628814 , Reply# 199 10/1/2012 at 18:28 (4,316 days old) by mickeyd (Hamburg NY) | ||

Looks like a Maytag Conventional parts manual~ Wonderful !!! | ||

| Post# 628816 , Reply# 200 10/1/2012 at 18:53 (4,316 days old) by wringer (x) | ||

|

Larry, Did you get the PU that I alerted you to on ebay or was there another one available there? Glad you got it at that price. Looks like a factory parts department with a shipment ready for production !!!!! Looking good !! Jim | ||

| Post# 628837 , Reply# 202 10/1/2012 at 20:19 (4,316 days old) by wringer (x) | ||

|

Yep, I agree on spares. Glad you got it at the right price also. It will be interesting to hear what shape it is in when you get it. You can really be proud and when you begin to use her and hear her hum you will really be proud. Jim | ||

| Post# 628885 , Reply# 206 10/1/2012 at 23:32 (4,316 days old) by qsd-dan (West) | ||

|

Synth Grease

A problem I have had using high quality synthetic greases is that it doesn't stick very well to gears. I learned this early on when re-packing gear boxes in antique fans. It does work well in roller and sleeve type bearings, not so great in gears, especially those exposed to high heat (grease can sometimes turn into a liquid) or just plain exposed to the elements. My 2 Cents.

This is what I use to repack gears and have had great success in using it. Not sure if it's the best application for wringer washers (perhaps Geoff can chime in), but it's something to keep in mind. CLICK HERE TO GO TO qsd-dan's LINK | ||

| Post# 629260 , Reply# 209 10/3/2012 at 19:19 (4,314 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

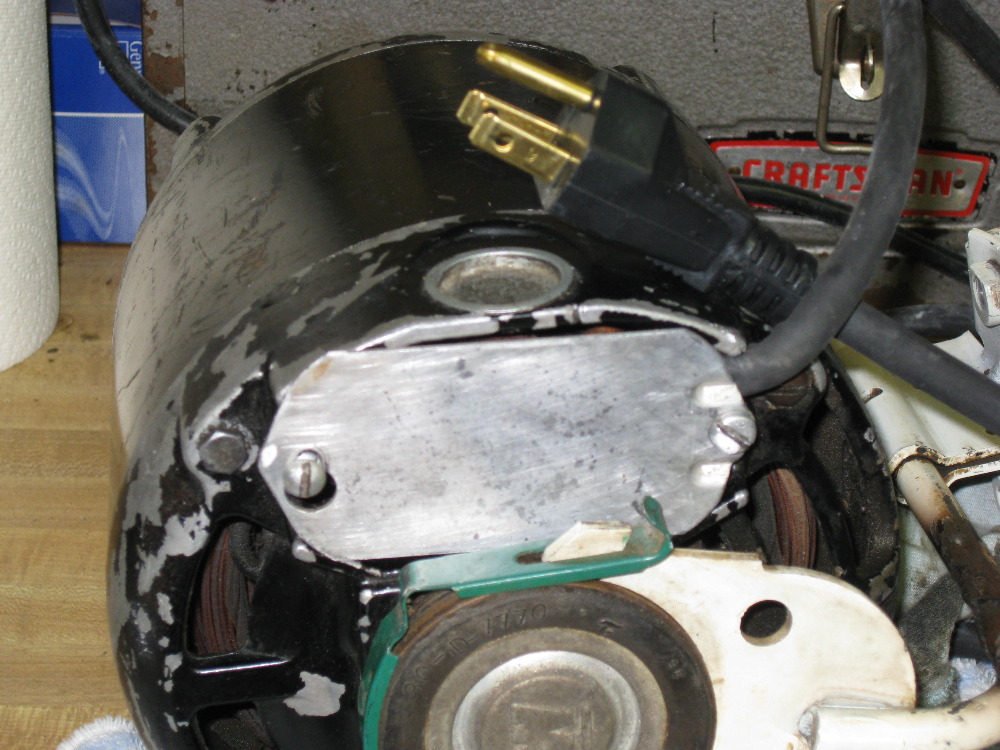

And after you replace the cover, it's unnoticeable! I was surprised to see mine has a Westinghouse motor. I'd only heard about GE and Delco motors in these Maytags. And now, back into the washer it goes!

| ||

| Post# 629265 , Reply# 211 10/3/2012 at 19:54 (4,314 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

One more picture of the washer in re-assembly mode. I know it's too soon to put the wringer back on but I wanted to make sure everything would fit correctly after the both drives were re-worked. And it DID!

| ||

| Post# 629270 , Reply# 212 10/3/2012 at 20:03 (4,314 days old) by mickeyd (Hamburg NY) | ||

Close enough to win the cigar | ||

| Post# 629271 , Reply# 213 10/3/2012 at 20:10 (4,314 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

AND! It's 100% Guar-uuu-teed and gen-U-wine imitation 110% imported from Mexico from Haney International Enterprises Inc! And as I always said, better to have a goose neck that a turkey neck. | ||

| Post# 629299 , Reply# 214 10/4/2012 at 00:41 (4,314 days old) by stan (Napa CA) | ||

Larry

That looks like the same goose neck I got for mine at a local appliance store. From what I can see you've done the same as I did and used the old style hose clamp.

Not sure I understand the new electric cord? I can see the two wires from the cord (one green) but don't see the third? Am I having a blonde moment? The 4 ounce of grease...what kind of grease did you decide to use use in the "space available" Had mine over on it front today checking things out ( preparing my thoughts for replacing the seals) and noticed that the bolt that holds the power unit in place, is not tightened down firmly to the frame. When I did tighten it down snug, and turned the machine on, it didn't sound right! Had to loosen it back to where it was, while it was running, to get her quiet again. Just a observation I thought I'd pass on in case you find the same. | ||

| Post# 629310 , Reply# 215 10/4/2012 at 02:51 (4,314 days old) by stan (Napa CA) | ||

Oh I see | ||

| Post# 629338 , Reply# 217 10/4/2012 at 08:40 (4,313 days old) by wringer (x) | ||

|

Gosh, I wonder how many members are like me and wait daily for a progress report. She sure is lookin good !!!!! Can't wait to see her all done and doing laundry !! I know you can't either LOL. Great going Larry !!! Jim | ||

| Post# 629756 , Reply# 225 10/6/2012 at 01:50 (4,312 days old) by stan (Napa CA) | ||

Larry

Don't know how much of a departure from the service manuals instructions for "re assembly" that is, but sounds O.K to me!

You would also hook up the right angle drive and wringer post, prior to the installation of the tub though, right? Without looking (at the manual) I would think filling the P.U and closing it up with the center plate (two bolts) right away, is where my mind go's first, but you have interesting idea! That might make it easier! Do you think the P.U, and center plate, would be stable enough with out it being bolted to the tub, to "run" without ? Geoff where are you! | ||

| Post# 629818 , Reply# 230 10/6/2012 at 11:39 (4,311 days old) by stan (Napa CA) | ||

Geoff | ||

| Post# 629839 , Reply# 233 10/6/2012 at 15:27 (4,311 days old) by geoffdelp (SAUK RAPIDS) | ||

|

Larry Absolutely! Plug it in and make sure everything works; that's the way to do it!! You'll also hear how quiet it is without the aluminum tub to make an echo. Can't wait ... I'll check back later this weekend. Good luck but I'm sure you've got it!! :-) | ||

| Post# 629853 , Reply# 234 10/6/2012 at 16:22 (4,311 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

Almost Done! But I'm having a problem with the pump hook up. There's a shaft that connects to the on/off lever. But where does it connect to the pump? There's just this hook like bend on the other end but I don't see where it goes? | ||

| Post# 629855 , Reply# 235 10/6/2012 at 16:48 (4,311 days old) by stan (Napa CA) | ||

The hook

end go's threw a pre made hold on the pump U side down.

The rest of the linkage where it connects to the lever, is a little tricky to get it to have the right amount of tension with the spring, and so forth. The two bolts that hold the end of that to the lever, are the tricky spot. Depending on how deep the first one is threaded, will determine the distance the fly wheel travels on the pump before engagement takes place. You'll see! And after a adjustment, you'll get it! | ||

| Post# 629857 , Reply# 236 10/6/2012 at 16:58 (4,311 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

This? Is this it? Because that end of the shaft is too big for the hole in the pump. Won't fit through it.

| ||

| Post# 629860 , Reply# 237 10/6/2012 at 17:09 (4,311 days old) by stan (Napa CA) | ||

Sure looks like it to me! | ||

| Post# 629863 , Reply# 239 10/6/2012 at 17:27 (4,311 days old) by stan (Napa CA) | ||

The other end that  | ||

| Post# 629866 , Reply# 240 10/6/2012 at 17:43 (4,311 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

Yea! The pump's in and working. Noe for the tub. After dinner it will be wash time! | ||

| Post# 629872 , Reply# 242 10/6/2012 at 19:01 (4,311 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

The underside Hasn't looked this clean since she came off the assembly line in June 1964. It may not last but here's what it looks like today.

| ||

| Post# 629883 , Reply# 243 10/6/2012 at 20:02 (4,311 days old) by stan (Napa CA) | ||

Beautiful

Umm what "next time" the hell you've been through, can't imagine you'd even consider a next time LOL!

A couple of thing I"ll give you an heads up on, now that she's ready to wash, and pump... If the pump lever linkage is adjusted a little to tight, the lever may pop back over to the OFF position by itself, its no big deal (mine dose this and haven't bothered to re adjust) As Mike said up thread, the pumps are mighty, and will empty that tub right quick! While its pumping out, don't be surprised if you lid rattle's !LOL (mine dose, and never been able to stop) Also no big deal. After what you been through this little things, will seem like heaven! Beautiful job Larry | ||

| Post# 629908 , Reply# 246 10/6/2012 at 22:09 (4,311 days old) by alr2903 (TN) | ||

|

Oh no, Larry i have followed your posts and great photo's. I had a moment of worry, when you mentioned using the that alternate PU. Maybe the old girl, just wants her original heart back, so to speak. You have reworked all of it maybe just too much "new" at one time. alr | ||

| Post# 629909 , Reply# 247 10/6/2012 at 22:13 (4,311 days old) by stan (Napa CA) | ||

I'm dying here

My God this old girl is being difficult!

Where could the Bosco come from? You had all that cleaned out? Leaks! ...You had new tub bolts and new rubber washers?? Could it be the center plate seal? I know you put a new one on, before the tare down, but ... ?? Think we all know you well enough now, that we know this wont get the better of you, but I'll tell you, it sure causes me to pause at the idea of doing mine! I know that I'll have to do this sooner or later, but after reading this... Umm, think that will be a later LOL | ||

| Post# 629918 , Reply# 249 10/6/2012 at 23:09 (4,311 days old) by stan (Napa CA) | ||

Think the

cork gasket is certainly worth a try at this point, so is the "Goop" (good stuff) Don't know what P.U is better? my guess is that the one that it came with, locked up because of that piece of metal.

Did you hear the pump when it was engaged? They make quite a roar when the fly wheel and pump wheel meet. It may be just a little short, (adjustment) where it's not quite touching. Sure can't blame you for taking a rest from it, you certainly deserve one! We're here to help, when you you try again! | ||

| Post# 630046 , Reply# 254 10/7/2012 at 15:24 (4,310 days old) by stan (Napa CA) | ||

Geoff | ||

| Post# 630080 , Reply# 256 10/7/2012 at 19:48 (4,310 days old) by stan (Napa CA) | ||

Your hilarious dude

I knew it would'nt get you down for too long LOL

Think we need Geoff for those questions, but one thing for sure is you have to get the water out of the right angle drive. My vote is that you use to the P.U she was came with, but lets wait for Geoff to stop by! What little screw are you all talking about?Do you have pics so we can see? (your probably sick of pics by now, but we enjoy them!) | ||

| Post# 630087 , Reply# 258 10/7/2012 at 20:13 (4,310 days old) by stan (Napa CA) | ||

Oh I see  | ||

| Post# 630153 , Reply# 262 10/7/2012 at 22:40 (4,310 days old) by stan (Napa CA) | ||

just looked at mine

and my E appears to have some kind of rubber plug in it like Jim's E! Never noticed it before had to poke around on it to see and feel!

I probably poked a hole in it trying to find out LOL Also noticed that all the gulmite bolts have a rubber washer with the exception of the two that hold the P.U ?? So either they were not used there, or the edges of mine have disintegrated ? Dose anyone know why the gulmite bolts should not be re used (with new rubbers) ? Larry have you checked that agitator shaft seal (just to make sure) Just brainstorming here, but what about wrapping the threads of each bolt with a little teflon tape (again just to make sure) | ||

| Post# 630160 , Reply# 264 10/7/2012 at 23:16 (4,310 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

Stan, I did remove and reinspect and clean the agitator seal last week. It appeared to make a good seal when I put it back in. | ||

| Post# 630167 , Reply# 265 10/8/2012 at 01:03 (4,310 days old) by stan (Napa CA) | ||

Geoff

I'm confused! (wouldn't be the first time)

is the rubber over the screw, or rubber under the screw? I don't see a screw in mine just see rubber? And dose this screw (if present in the E model) actually serve a purpose, like helping to hold the center plate to the P.U (or P.U to center plate) Can only imagine it's there to help with alignment, configuration, or something? Also, is there a reason NOT to re use the same bolts, (in my case the gulmite) and what are your thoughts about using a little teflon tape on the threads of the bolts, prior to installation? (sorry for all the questions Geoff) LOL | ||

| Post# 630340 , Reply# 270 10/8/2012 at 21:36 (4,309 days old) by stan (Napa CA) | ||

Your scarrin me ! | ||

| Post# 630570 , Reply# 272 10/9/2012 at 23:30 (4,308 days old) by stan (Napa CA) | ||

Good job. | ||

| Post# 630607 , Reply# 273 10/10/2012 at 08:43 (4,307 days old) by geoffdelp (SAUK RAPIDS) | ||

|

Nice, Larry. It is pretty simple, isn't it? Kind of reminds you of the center plate seal, doesn't it? Fun to watch; isn't it Stan? | ||

| Post# 630610 , Reply# 274 10/10/2012 at 09:00 (4,307 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

Stan, It's already re-assembled so I can't take another picture. But looking at it I can tell that the shaft is round until it's through the unit. Then about maybe the last 2 inched has a flat side to secure the bolt from the pulley. | ||

| Post# 630681 , Reply# 275 10/10/2012 at 16:12 (4,307 days old) by stan (Napa CA) | ||

O.K thats

what I thought!

Yes it is fun to watch, wish I could be there in person to see, that would be more fun. For now we'll just have to rely on Larry's pics! Out of curiosity...is it just the die hards hanging on here? I know Jim, Geoff, myself, and of course Larry, are tuning in on this? Any of the rest of you out there peeking in? LOL | ||

| Post# 630690 , Reply# 276 10/10/2012 at 16:38 (4,307 days old) by d-jones (Western Pennsylvania (Pittsburgh Area)) | ||

Stan

I don't have a wringer washer or any experience with them, so I haven't had anything worthwhile to add to this thread. But it's still very interesting, so I've been following it closely since it morphed from moving a wringer to essentially overhauling one. And even though I'm not commenting on his progress, I'll keep checking in until Larry finishes this project or throws in the towel. So yes, others are following this thread. ; - )

| ||

| Post# 630706 , Reply# 277 10/10/2012 at 17:44 (4,307 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

Mikeyd still checks in from time to time. alr2903 Also made comment after last weekends disasterous adventures. Hopefully, the only towel throwing I'll be doing will be a dirty one into a WORKING and water tight, non-oil leaking, refurbished E2LP Maytag Conventional Washer! I think I'm due! | ||

| Post# 630769 , Reply# 278 10/10/2012 at 22:51 (4,307 days old) by stan (Napa CA) | ||

whats  | ||

| Post# 630970 , Reply# 280 10/11/2012 at 21:40 (4,306 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

Here's the center plate before the plug is inserted. This is what becomes the plug. You pull it through and get it as tight as you can. Then trim off the ends with a razor blade. The gasket, O-ring is in the picture but not inserted.

| ||

| Post# 630971 , Reply# 281 10/11/2012 at 21:42 (4,306 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

Here's After the plug operation is completed. The gasket is inserted where it goes for the tub installation.

| ||

| Post# 630975 , Reply# 282 10/11/2012 at 21:46 (4,306 days old) by geoffdelp (SAUK RAPIDS) | ||

|

Oh boy ... nicely done, Larry! That tub is beautiful!! I use Brillo pads with "oxygen cleaner" in them; they work well, too. That plug material really makes a tight seal, doesn't it? | ||

| Post# 630996 , Reply# 284 10/12/2012 at 00:01 (4,306 days old) by stan (Napa CA) | ||

Beautiful  | ||

| Post# 630998 , Reply# 285 10/12/2012 at 00:23 (4,306 days old) by stan (Napa CA) | ||

Just happened to

think! (after looking at the pics)

Did we ever determine what the little screw ( now plug) was intended for by the manufacture? Dose it have a purpose? is there a receiving hole on the power unit for it? Was it intended to be a possible way of adding lube to the power unit, just by removing the screw, adding lube, and then replacing the screw? Talk among yourselves LOL | ||

| Post# 631071 , Reply# 287 10/12/2012 at 12:34 (4,305 days old) by mickeyd (Hamburg NY) | ||

Talk about washer art....... | ||

| Post# 631095 , Reply# 289 10/12/2012 at 15:21 (4,305 days old) by mickeyd (Hamburg NY) | ||

HI Larry, The original hose is thick, stiff, and hard. To get it off the holding couple, the operating instructions say to grasp the hose with both hands and pull upward to release the hose from its post. That always stuck in my head: all those rituals to begin the drain sequence. I often wondered if the upward pull had anything to do with aligning the parts below. Maybe so, maybe not.

Then one rosy washday afternoon, I engaged the pump, but nothing happened. So I gave a yank on the longer, more pliable replacement hose, and thar' she blows.....

Thereafter, she always blew just fine. Just a fluke perhaps, and I do whatever works, especially if it's easy. It's worth a try, and please believe Larry, that's I have nowhere near the skill of many here, so don't expect mechanical miralces from me. "Ah gar un teeeeee." ; 'D | ||

| Post# 631174 , Reply# 292 10/12/2012 at 22:25 (4,305 days old) by geoffdelp (SAUK RAPIDS) | ||

|

True, Larry. But I have to wonder if you have "too much" hose creating too much slack on the pump. The original hoses were installed flush to the side of the washer cabinet and had some resistance while in the hanger; it would stay put. Something to mull over ... | ||

| Post# 631190 , Reply# 293 10/13/2012 at 00:00 (4,305 days old) by stan (Napa CA) | ||

Humm

I don't think I get it either!

However I've already done, what Larry's done, I made my own hose, and goose neck, I leave mine hooked to the sink. The only time I unhook it from the sink is when I'm finished with all the wash, and I'm draining the left over into a bucket! I don't push or pull on anything, just move the lever to ON or OFF. No problem. Pump dose what I want, when ON... empties the tub right quick! LOL | ||

| Post# 631980 , Reply# 296 10/16/2012 at 00:05 (4,302 days old) by stan (Napa CA) | ||

Hi Larry  | ||

| Post# 632106 , Reply# 298 10/16/2012 at 12:42 (4,301 days old) by mickeyd (Hamburg NY) | ||

"Anticipation" ~ the song. She's tapping her foot waiting for the pump, and then it'll be all quiet on the western front, and you can move on. I really can't wait to see what machine you find for your next project. Hmmmmm, I wonder what it will be?

PS: The tug on the hose may be the secret move..... shhhhhh, but the flooding is funny, pulling too hard, indeed! | ||

| Post# 632154 , Reply# 299 10/16/2012 at 17:51 (4,301 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

Anticipation - Now I won't get anything done Mike. I got that Carly Simon song stuck in my head with a real hankerin' for some Gen-U-Wine, Heinz Ketchup! MMmmmmmmmm Heinz. The slowest ketchup in the west! | ||

| Post# 632210 , Reply# 302 10/16/2012 at 22:37 (4,301 days old) by stan (Napa CA) | ||

"refurb of the transmission, hasn't seized up at all | ||

| Post# 632221 , Reply# 304 10/16/2012 at 23:45 (4,301 days old) by qsd-dan (West) | ||

|

| ||

| Post# 632341 , Reply# 306 10/17/2012 at 13:08 (4,300 days old) by mickeyd (Hamburg NY) | ||

In full agreement with Jim. | ||

| Post# 632538 , Reply# 308 10/18/2012 at 08:56 (4,299 days old) by wringer (x) | ||

|

OHHHHHHHHHHHHHHHHHHHHHHHHHHHH the suspense is killing me !!!!!!!!!!!!!! Waiting here with baited breath Larry. I would have never "thunk" it at all. But the end result is worth thunking about !!! Best Jim | ||

| Post# 632740 , Reply# 311 10/18/2012 at 21:35 (4,299 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

Saturday's Wash Day! And it will be 9 weeks to the day I brought Bessie Mae, as Jim calls her, home. Never thought it would take so long. But never thought I'd learn so much either. This isn't some touch up machine. This is a refurbished E2LP machine from 1964 that looks DAMN good!

| ||

| Post# 632741 , Reply# 312 10/18/2012 at 21:39 (4,299 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

Here's a shot from the side with the "new" pump lever. Not exactly level . .. I haven't had the best of luck with decals . . but . . . .Beats a poke in the eye with a sharp stick!

| ||

| Post# 632771 , Reply# 313 10/19/2012 at 00:22 (4,299 days old) by stan (Napa CA) | ||

Looks Great Larry | ||

| Post# 632812 , Reply# 314 10/19/2012 at 08:32 (4,298 days old) by geoffdelp (SAUK RAPIDS) | ||

|

Looks great, Larry!! Can't wait to see it in action. Sounds like you have mastered the pump now, too. Ready to go!!! | ||

| Post# 632816 , Reply# 315 10/19/2012 at 08:46 (4,298 days old) by wringer (x) | ||

|

This is the day I have been waiting for. Bessie May looks beautiful setting there ready to do laundry. You did an outstanding job Larry !!!!!!! You can be very proud of what all you have gone through. Congrats and let us see her full of laundry doing her job :-). Best ! Jim | ||

| Post# 632864 , Reply# 316 10/19/2012 at 15:40 (4,298 days old) by mickeyd (Hamburg NY) | ||

Shimmering Just look at the back wall of the tub! Waves of shimmer. And then the hook, hose, and control shot. Sacrilege, I know, but the hose and pump look better than the originals. "Anticipaaayyyytion..........

It will be interesting to see how you conduct the rinse operation: right in "Bessie May," in another machine, or in laundry sinks. It will all be a grand surprise to see you actually washing, and your method. Again, wait till you see how fast the Maytag pump moves water. As far as I've seen, it has no equal in any other conventional machine. I've had races with the Tag, the Norge, the Easy and the Kenmore. | ||

| Post# 632985 , Reply# 317 10/20/2012 at 08:29 (4,297 days old) by wringer (x) | ||

|

Well, it is Saturday AM and washday for you Larry. Hope to see some pics of Bessie May in action. I know you are more than ready to use her as she was built and rebuilt to use. Happy Maytagging today !! Best, Jim | ||

| Post# 633040 , Reply# 319 10/20/2012 at 13:42 (4,297 days old) by bradross (New Westminster, BC., Canada) | ||

Wow! Mission accomplished!

Larry, this has been an amazing success with a very involved - and apparently frustrating - restoration project. As I think Geoff or Jim said earlier on, with good care, this machine could easily last for several future generations! Just think - my model 30 is from 1935 and still working with original parts and motor! These things were built like tractors!

Don't ya just love a wringer washer??? I love the fact that I'm actually "doing" the laundry - there's something engaging about it, rather than just throwing it in the machine and walking away. Not to mention the memory recall from childhood! Congrats on a job beautifully done! | ||

| Post# 633054 , Reply# 320 10/20/2012 at 14:50 (4,297 days old) by d-jones (Western Pennsylvania (Pittsburgh Area)) | ||

Great Job Larry!

Because of the way you documented your progress so thoroughly with photos and commentary, this has been one of the more interesting rebuilds I've seen here on the blog, and as I said earlier, I don't even have a wringer washer. Thanks for taking the time to share it with all of us, and congratulations for a job well done! There is something very satisfying about seeing a vintage machine brought back to life after years of neglect. In this case, something old is new again.

| ||

Post# 633725 , Reply# 322 10/23/2012 at 14:14 (4,294 days old) by rp2813  (Sannazay) (Sannazay) |

||

After seeing this thread hanging near the top of the list for over two months and noticing it had more than 300 replies, curiosity got the best of me and once I started reading, I couldn't stop.

That having been said, let me also say this: Congratulations!

Larry, you have shown everyone here that with a combination of dedication, determination and perseverance, there is virtually no such thing as a lost cause when it comes to a Maytag washer. I nominate you for "Outstanding Achievement in Clothes Washer Restoration, Non-automatic" as well as "Outstanding Achievement in a Documentary Presentation."

This has been one of the most interesting threads I've seen here. Thanks so much for sharing. You really hit the ground running when you joined AWO, that's for sure!

Ralph | ||

| Post# 633787 , Reply# 324 10/23/2012 at 18:34 (4,294 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

And the PUMP I'm lovin' the pump!

| ||

| Post# 633791 , Reply# 325 10/23/2012 at 18:42 (4,294 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

And here's my favorite! A picture of the floor under the washer when I was finished. Isn't that something? No water, no oil. I waited a long time for that!

| ||

| Post# 633832 , Reply# 326 10/23/2012 at 21:45 (4,294 days old) by wringer (x) | ||

|

You are a proud Papa Larry and deservedly so !! She is a beauty. Jim | ||

| Post# 633839 , Reply# 327 10/23/2012 at 22:36 (4,294 days old) by stan (Napa CA) | ||

It's a beautiful site  | ||

| Post# 633971 , Reply# 329 10/24/2012 at 13:23 (4,293 days old) by wringer (x) | ||

|

Hypnotising water !! I don't think any of my gals does this. However, I don't remember ever looking at them running but no soap or agitation. I will have to look next washday. Again, AMAZING AND BEAUTIFUL JOB !!! Jim | ||

| Post# 634017 , Reply# 330 10/24/2012 at 18:08 (4,293 days old) by stan (Napa CA) | ||

Steve  | ||

Post# 634058 , Reply# 332 10/24/2012 at 21:25 (4,293 days old) by rp2813  (Sannazay) (Sannazay) |

||

Speaking of your first post -- | ||

| Post# 634075 , Reply# 333 10/24/2012 at 22:20 (4,293 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

That's very true. But it didn't know that back then. Sideways, upside down, let it drip. It was all going to have to come apart anyway! | ||

| Post# 634339 , Reply# 334 10/25/2012 at 23:00 (4,292 days old) by bradross (New Westminster, BC., Canada) | ||

Great shot of the water ripples!

Larry, it's a work of art! Great shot! And what a relief it must be - to see no drips of ANYTHING under that machine when it's running. Wish I had the space (or facility) to completely dismantle my Model 30 and replace all the gaskets. Being 70+ years old, not surprising that there's a bit of oil seepage around the joints of the transmission casing, etc. But amazingly, it's nothing major. So I'll just keep using it - it's not like it's actually dripping or anything. But I'd still like it perfectly sealed!

Thanks again for posting all the pics of your restoration project! | ||

| Post# 634365 , Reply# 335 10/25/2012 at 23:30 (4,292 days old) by mickeyd (Hamburg NY) | ||

Spooky water ghosts for Halloween John combo took a pic of the famous Maytag Halo of Heat, removed from the dryer and suspended in space--first thing that came to mind when I saw your ripples. The "pattern" is almost the same. I'll try to find it for its eerie similarity.

And I want to tell you about double wringing, tomorrow, which came to mind just a few minutes ago after imitating your method of draining the tub while wringing and returning the load right back to the E2L for rinsing. | ||

| Post# 634545 , Reply# 336 10/26/2012 at 16:44 (4,291 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

CORRECTION: "while wringing and returning the load right back to the E2L - P, for rinsing." | ||

| Post# 634551 , Reply# 337 10/26/2012 at 18:16 (4,291 days old) by mickeyd (Hamburg NY) | ||

pee pee Only thru implant surgery.

Mine came with a pump and the label reads E2LS. Hmmmmm...... Maybe it's what we call a "SUDS." I'll have to see. All jokes.

So I was doing a big load of darks, that had been soaking out salad dressing on a few long sleeve cotton jerseys. Next, I started the pump and I wrung, not wanting to re-use the old cold water. You already know how quick these gals wring, so the tub was empty and I though of you.

Then instead of rinsing else where, I started the water in through my inlet mod, and rather than lift the load from the movable cart behind the wringer, I put the load thru the wringer from the cart back into the washer. A ton of water came out ! Since the drain board had automatically reversed, I forgot to provide for the run-off, and the second wring actually flooded the linoleum, so I mopped the floor which needed it anyway.

Had heard of this ancient ritual of double--even, tripple--wringing. This was my first attempt, and YOU are the efficient cause, so Thank You, Lawrence. It was pretty cool. Try it on those towels and let us know.

| ||

| Post# 634683 , Reply# 342 10/27/2012 at 12:06 (4,290 days old) by stan (Napa CA) | ||

Clotheslines | ||

| Post# 636181 , Reply# 345 11/3/2012 at 17:01 (4,283 days old) by qsd-dan (West) | ||

|

| ||

| Post# 636258 , Reply# 348 11/4/2012 at 00:29 (4,283 days old) by stan (Napa CA) | ||

OMG! | ||

| Post# 636369 , Reply# 350 11/4/2012 at 09:02 (4,282 days old) by shankstr (St. Louis, Missouri) | ||

|

The New Centerplate Still has the screw hole. I did buy the rubber plug for it though.. | ||

| Post# 636373 , Reply# 351 11/4/2012 at 09:19 (4,282 days old) by scoots (Chattanooga TN) | ||

"Your Mother sews socks that smell!"  | ||

| Post# 636467 , Reply# 353 11/4/2012 at 12:54 (4,282 days old) by stan (Napa CA) | ||

Jim  | ||

| Post# 636809 , Reply# 354 11/5/2012 at 17:11 (4,281 days old) by shankstr (St. Louis, Missouri) | ||

|

So larry What kind of grease did you put into the lower verticle wringer shaft? I was re-reading your post but you didn't say for sure. I saw the part where Phil said to use synthetic grease but Geoff recommended the original Maytag grease because it was oiler. So what did you do? Steve | ||

| Post# 636849 , Reply# 356 11/5/2012 at 19:05 (4,281 days old) by shankstr (St. Louis, Missouri) | ||

|

I'm thinking I'll do the same OK cool. I bought the synthetic so I guess I'll go with it too. I checked around the net and couldn't find any original Maytag grease anyway. I also bought the Maytag transmission oil online..34oz worth...just in-case I have to pull it apart again :) Steve | ||

| Post# 636862 , Reply# 358 11/5/2012 at 19:41 (4,281 days old) by stan (Napa CA) | ||

Larry  | ||

| Post# 636870 , Reply# 359 11/5/2012 at 19:47 (4,281 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

None None that I can see anyway. Is there any difference if you use Penzoil 40 wt. or 40 wt.Quaker State? Not much anyway. I think 40 wt. is 40 wt. and 90 wt. is 90 wt. Plus, at the rate I go through it, it's just more economically sound to use the cheap stuff! | ||

| Post# 636878 , Reply# 360 11/5/2012 at 20:15 (4,281 days old) by stan (Napa CA) | ||

So  | ||

| Post# 636901 , Reply# 361 11/5/2012 at 22:01 (4,281 days old) by e2l-arry (LAKEWOOD COLORADO) | ||

|

I'm hoping tomorrow night Stan But I somehow messed up my thumb. It feels like a pulled a tendon. I can't even pick up a glass or write with my right hand and I'm right handed! I've been putting ice on it trying to work it out. But if it's not better tomorrow there's no way I'll be able to re-assemble a washer. | ||

| Post# 636918 , Reply# 362 11/6/2012 at 00:56 (4,281 days old) by stan (Napa CA) | ||

Damm  | ||

| Post# 637395 , Reply# 365 11/7/2012 at 17:35 (4,279 days old) by shankstr (St. Louis, Missouri) | ||

|

I've got my fingers crossed!! | ||

| Post# 638195 , Reply# 368 11/11/2012 at 08:15 (4,275 days old) by wringer (x) | ||

|

Well, no one can say you don't deserve her to operate as a NEW gal with all of the work you have put into her. I am glad/happy that you have been successful. I know it was very trying to you and we all here were pulling for you. Many happy wash days ahead await you Larry ! Jim | ||

| Post# 793016 , Reply# 369 11/9/2014 at 23:21 (3,547 days old) by Patrick () | ||

|

Last reply was a year ago, but asking anyway. What are you using to clean the inside of the tubs so well? | ||

Comes to the Rescue!

Comes to the Rescue!