|

Thread Number: 76

Workin' on the Maytag Combo |

[Down to Last] |

Post# 45018 9/13/2004 at 18:46 (7,256 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

I've started some initial work on the Maytag combo I brought home a week ago, the machine looks very good overall but it appears to have been used as a dryer for a long time. There is lint and hard-water scale everywhere which fortunately has been fairly easy to get rid of. I started with a vacuum and finished with a hose & needle spray to clean behind the drum. I removed the blower and pump, dis-assembled and cleaned them thoroughly before reassembling them with fresh turbine oil lubrication. This is one of the most difficult machines to work on, there is so little room around the drum for all the components - the water pump is the WORST, mounted on the bottom of the drum!! Check out the pic of the sump, there are four hoses connected to it!! So far it's going well and hopefully it will be washing & drying away very soon.

CLICK HERE TO GO TO gansky1's LINK | ||

|

Post# 45023 , Reply# 1 9/13/2004 at 18:59 (7,256 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

| Post# 45029 , Reply# 2 9/13/2004 at 20:02 (7,256 days old) by golittlesport (California) | ||

| ||

Post# 45044 , Reply# 4 9/13/2004 at 22:27 (7,255 days old) by appnut  (TX) (TX) |

||

|

| ||

Post# 45050 , Reply# 6 9/14/2004 at 00:43 (7,255 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

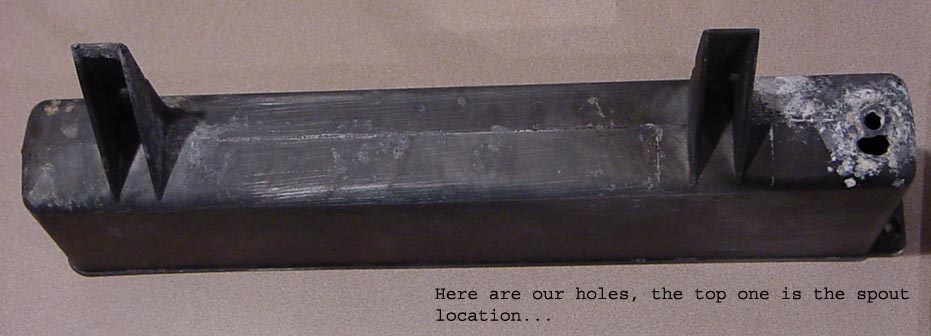

Our first snag...

I did a little more putzing tonight and removed the fabric softener dispenser well for cleaning. During my work earlier, I discovered the hose from the softener well to the sump (that's #1 Brent) was broken off the well. Thinking it was a plastic well (a long narrow box directly under the door opening) I pulled it out and found a cast pot-metal box, completely full of dried softener. I cleaned it completely and retrieved the rubber stopper from the bottom of the box. For those of you familiar with the dispensers on higher-end Kenmore or Whirlpool, this a very similar design with a solenoid and plunger, the stopper or plunger is pulled up by the solenoid in the final rinse, releasing the contents of the container into the outer tub. Unfortunately, the spout of the well is completely dissolved away leaving nothing to attach a new hose to and there is also a hole eaten through the metal very near the original spout location. I'll have to give the problem some more pondering and see if I can come up with a solution to make this work again, filling the "extra" hole is no big deal, JB Weld to the rescue, but I'm wondering how to get a new spout attached. I wouldn't want the judges to take off points for lacking dispensers! I haven't yet looked at the bleach dispenser (hose to sump #2) but it appears to be OK so far. (box/well is pictured with the bottom side facing up) Brent - see if you can guess what the other two hoses in the sump are are for... ;-)

| ||

Post# 45063 , Reply# 8 9/14/2004 at 08:29 (7,255 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

Hi Brent- This piece is metal, I'm sure it could be re-created but I wonder what the cost would be... There is no flush with clean water, that probably would have saved the dispenser from it's current condition but it's simply a holding tank for the softener until it's released in the final rinse cycle. The whole tank was nearly full to the top with dried, caked on softener. It was pretty gross looking, but I think she only used Downy so it did have a nice vintage smell! Pretty close on the hoses to & from the sump - bleach, softener, drain to pump hose and the air dome (water level control) hose are all attached to the bottom of the drum. WP/KM was the only one with a recirculating spray system. I'm surprised it's not completely rusted away but it doesn't look like this machine was used as a washer for all that long. I was told that the user/owner of this combo had another washer in the basement (probably a wringer) so that explains the low washer-use and more use as a dryer. | ||

Post# 45064 , Reply# 9 9/14/2004 at 08:33 (7,255 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

| Post# 45104 , Reply# 10 9/14/2004 at 17:04 (7,255 days old) by Cadman (Cedar Falls, IA) | ||

Greg, why not try this? www.muggyweld.com/potmetal.html... I've had good luck brazing regular metals in the past with a store-bought propane/oxy torch, never tried pot metal before though. Cory | ||

Post# 45111 , Reply# 11 9/14/2004 at 19:10 (7,255 days old) by appnut  (TX) (TX) |

||

|

Brent, the first versions (the wide ones) of the WP and LK Combos had a similar routine of either 30 seconds or 1 minute of tumbling before it tried spinning again. I don't know if this was timed by a similar type of timer, but Robert will be able to shed light on this, if Greg doesn't. But this happened many a time when I was a kid and it also happened when I did that load in Robert's WP in Minnie.

| ||

Post# 45114 , Reply# 12 9/14/2004 at 19:29 (7,255 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 45144 , Reply# 14 9/15/2004 at 07:42 (7,254 days old) by appnut  (TX) (TX) |

||

|

Brent, WP ceased marketing their combos sometime after 1964 or 1965. Sears stopped around 1972 or 1973 (maybe a bit later). I still can see the ad in the sears catalog they were on closeout and order before you can't. I felt so sad. The main reason I believe they stopped marketing them was because of the, by-then, lmited capacity, the LONG wash & dry cycles. The "modern" housewife of the time was getting back into the workforce, who had time to wait for a load of laundry 1.5 to 2.0 hours later.

| ||

| Post# 45145 , Reply# 15 9/15/2004 at 07:51 (7,254 days old) by Brent-Aucoin () | ||

|

Interesting Bob Bob, During the spring I ran into an older Tech for Sears that told me during the late 60's many of the | ||

| Post# 45506 , Reply# 17 9/21/2004 at 04:15 (7,248 days old) by kenmore1978 () | ||

|

Sears and WP combos Interesting that WP ceased marketing their version of the combo so early, but that there apparently was enough volume in KM sales alone to keep the assembly line going. | ||

Post# 45534 , Reply# 18 9/21/2004 at 15:36 (7,248 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

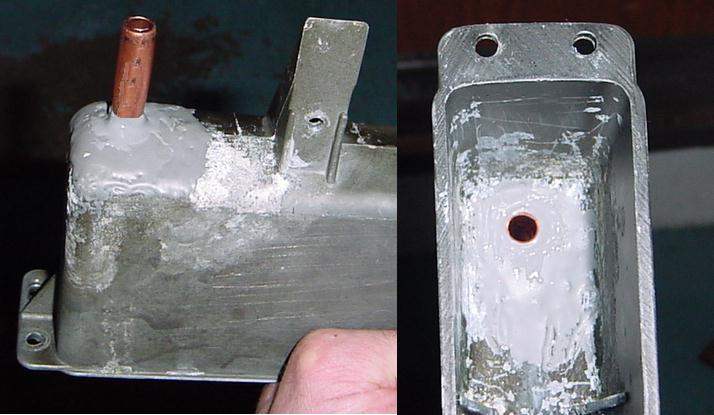

Dispenser Repair

I got the dispenser repair finished and was able to order a blower belt from a great company here called Precision Industries - they specialize in everything to do with motion & power transfer, bearings, etc. Last night I removed the front panel & boot to have better access to the dispenser mounting. Thinking the bleach dispenser was simply a funnel to the sump of the outer tub, I was surprised to see it was more of a "system" like those used in top-loading Maytag washers. There was a small hose from the tub and another leading to the sump so the dispenser (theoretically) was constantly flushed with water from the drum. As it turned out, the bleach dispenser became more of a sand trap over the years and was completely filled with grit and fine sand. It's all cleaned out and ready for more sand-trapping duty now! For the softener dispenser repairs, I first tried a small nylon flanged bushing & JB Weld but found that wasn't strong enough to attach a rubber hose to and rely on it to hold with some movement of the hose as the tub rocked back and forth during spins. I removed the nylon bushing and replaced it with a small piece of copper tubing that I flared on one end to allow a firm seating in the dispenser well and a smooth surface for the solenoid activated plug to seal against. It looks like it's going to work very well and seems to be very strong. I will reassemble the entire machine tonight and give it a run tomorrow (silicone around boot will need to cure) so check back, maybe we'll be ready to wash a real load! The belt will be a few days in coming so we'll have to be happy just washing for now, drying will come very soon!

| ||

Post# 45559 , Reply# 19 9/21/2004 at 23:55 (7,247 days old) by appnut  (TX) (TX) |

||

|

| ||

| Post# 45699 , Reply# 20 9/24/2004 at 09:54 (7,245 days old) by Brent-Aucoin () | ||

|

Missing post on Sears Tech Don't know why it does this to my post sometimes. What I said was that the old Tech told me in the wealthy women in parts of Atlanta would have two combo's side by side for laundry day! Isn't that cool. Brent | ||

| Post# 45700 , Reply# 21 9/24/2004 at 09:55 (7,245 days old) by Brent-Aucoin () | ||

|

Get your belt out yet? Hey there Greg, Did you get your belt yet that you found for your combo? I can't wait to hear about the first run! I bet you are excited! How are you going to get that big boy down to your basement by the way? Brent | ||

Post# 45714 , Reply# 23 9/24/2004 at 21:10 (7,245 days old) by appnut  (TX) (TX) |

||

|

| ||

Post# 45721 , Reply# 24 9/25/2004 at 00:13 (7,244 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

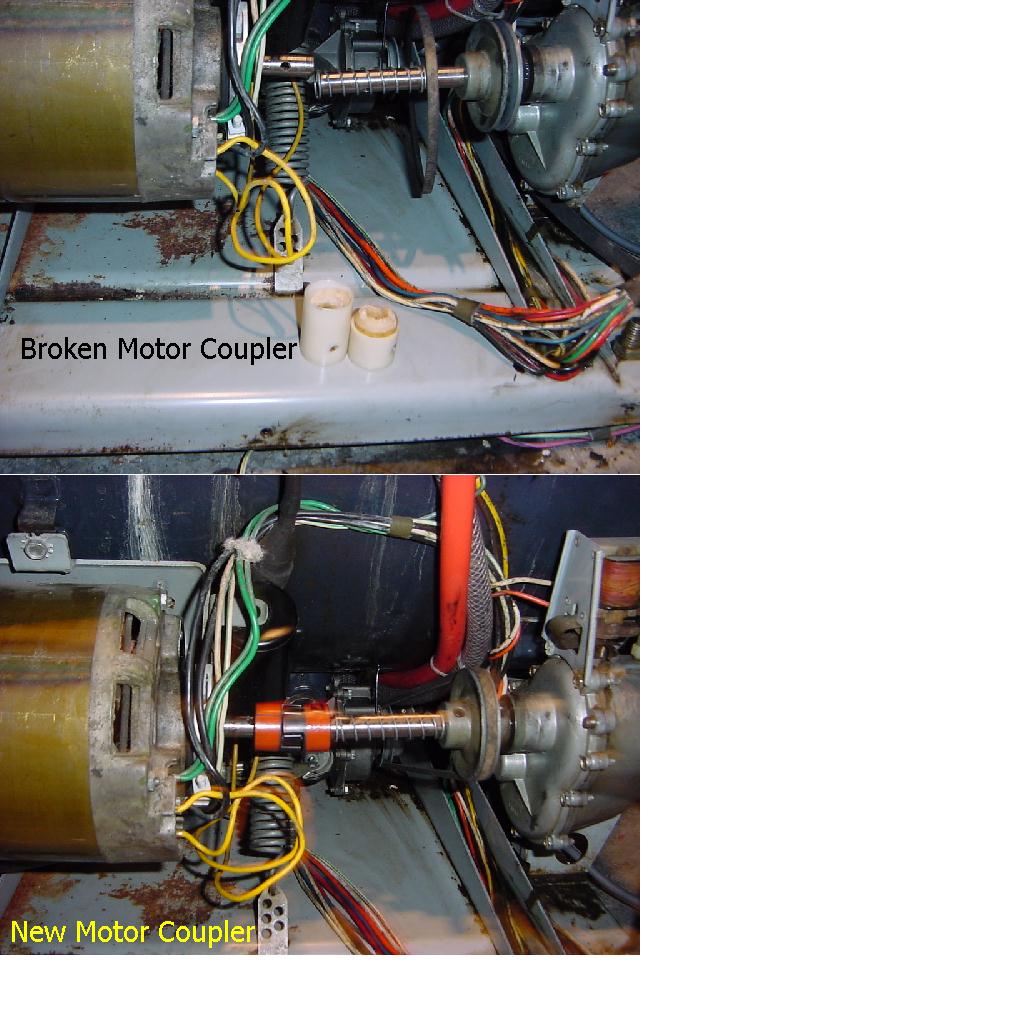

Weekend Combo Update

I've been plugging away at the combo as time allowed all week and we're very, very close to being ready to celebrate! I ran it through a couple of water tests this week and it passed with flying colors, however, when I filled the drum 1/2 full of clean rags (approx. 8lb load) we had tragic results... About halfway through the cycle, the drum stopped turning, the pump stopped pumping and I could only hear the motor spinning quietly along. Fearing the worst, of course, I started to inspect the tranny, drum belt, etc. trying to locate the problem. The problem was a coupling, similar to the principle applied in a DD Whirlpool/Kenmore washer. The motor is connected to the transmission shaft via a coupler made of a soft plastic sleeve in between a harder, plastic sheath that is split at the point where the two shafts meet. The purpose of this is to isolate the motor from the mechanical workings of the machine protecting the motor from a jammed drum or faulty transmission that would cause the motor to stall and overload. With just water in the machine, there wasn't enough load on this coupler to cause a problem, but when I added the load of rags, the inner soft plastic started to crumble and eventually broke in two. I believe this was caused by simple age degeneration. I went to my local supplier to see if I could replace the coupler, which interestingly enough was much different on my machine than was pictured in the service manual - probably a replacement during it's years in service. They didn't have an exact match for the part, but we came up with a solution that seems to work just fine. Here are a couple of pics so you can see the old broken coupler and the new one installed on the shaft(s). After this latest repair, I ran it through it's first full cycle without a hitch - and what a show it was!! I'll follow up with few more pics so you can see (a little through the tiny window) it running through it's paces. I'm still waiting on the blower-fan belt I ordered, it should be here on Monday or Tuesday. Hopefully that will fit and we'll be washing and drying - for now, I'm happy with the washing - we're almost there!

| ||

Post# 45723 , Reply# 25 9/25/2004 at 00:29 (7,244 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

First Wash Pics

Not much of a show through the window unless you peer around the edges of the drum. The clothes tend to ride the drum at 52 rpm, counter-clockwise until they reach about 11 or 12 o'clock when they crash to the bottom of the tub at about the 7 o'clock position where they are swooped up by the drum, through the pool of water sloshing around at the bottom of the drum and start the process all over again. It's very fun to watch and even more fun to hear all the water and clothes crashing together inside the drum.

| ||

Post# 45724 , Reply# 26 9/25/2004 at 00:30 (7,244 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

more washing pics | ||

| Post# 45733 , Reply# 28 9/25/2004 at 12:02 (7,244 days old) by alr2903 (TN) | ||

|

more washing pics. Greg great pictures Thank you for sharing with us. Would this of been a good washer in your opinion? Did CU ever test these? Thanks alr2903 | ||

Post# 45735 , Reply# 29 9/25/2004 at 12:53 (7,244 days old) by peteski50  (New York) (New York) |

||

Workin' on the Maytag Combo | ||

| Post# 46355 , Reply# 33 10/5/2004 at 21:21 (7,233 days old) by Brent-Aucoin () | ||

|

Greg, any luck with your belt? Hey there, Was wondering if you were able to find your blower belt for you combo? Have not seen any progress post lately, and am hoping that you are not having a hard time finding the belt that you need. Brent | ||

| Post# 46363 , Reply# 34 10/5/2004 at 21:53 (7,233 days old) by i70sn80sguy () | ||

|

excellent pictures The patience you have to renew this machine. You have my respect. | ||

Post# 46373 , Reply# 35 10/5/2004 at 23:56 (7,233 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

Work Continues

The combo is going very well actually, the last couple of weeks have been very busy and I've not had time to complete all the details. I did find a belt for the blower assembly, I ordered a 2L-320 (1/4" wide by 32" long) but it was too short and would have run much too tightly. I tried stretching it which did help but finally found a 2L-325 (32 1/2" long) belt that actually was intended for a Frigidaire Skinny-Mini which seems to work perfectly. I'm still not happy with the way the new motor-to-tranny coupler works, there's a little more vibration that I'd like, but I have an idea I'm going to try tomorrow so hopefully that will be the last hurdle to hassle-free laundry days! I will take some pictures of the suspension system tomorrow so you can see how it dampens off-balance loads and protects the machine from tearing itself apart. | ||

Post# 46389 , Reply# 36 10/6/2004 at 08:39 (7,233 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 46475 , Reply# 37 10/7/2004 at 21:48 (7,231 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Ohh I cant' wait | ||

Post# 46484 , Reply# 38 10/7/2004 at 23:53 (7,231 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

How many? | ||

Post# 46485 , Reply# 39 10/8/2004 at 00:01 (7,231 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

I am still working on the Maytag - the coupler I tried today worked perfectly for half a cycle so we're back to the hardware store to try again with some stronger materials and a little different application so I'll update again tomorrow. Each step is a learning process but we're very, very close now. While it was running ;-) it was most quiet I've ever heard it! Keep your fingers crossed... | ||

Comes to the Rescue!

Comes to the Rescue!