|

Thread Number: 78407

/ Tag: Modern Dryers

Fix or Replace? |

[Down to Last] |

|

| Post# 1024332 , Reply# 1 2/11/2019 at 19:16 (1,992 days old) by Pierreandreply4 (St-Bruno de montarville (province of quebec) canada) | ||

depends on the age of the washer | ||

Post# 1024334 , Reply# 2 2/11/2019 at 19:42 (1,992 days old) by DADoES  (TX,†U.S. of A.) (TX,†U.S. of A.) |

||

†

My aunt's Duet of the same model blew the motor board last year.† I diagnosed the problem, ordered the part from SearsPartsDirect.com (they paid so I don't recall the $ but it was less than now), uncle did the replacement when it arrived. Part Number W10374126 --> WPW10374126 There are several new choices on eBay $169.99, $171.99, $189.95.† Also probably some used choices if you feel comfortable going that route. Can also have it repaired via CorecentricSolutions.com $150 + shipping & taxes. | ||

Post# 1024336 , Reply# 3 2/11/2019 at 21:18 (1,992 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

WP Duet, Fix Or Replace ? Hi, How many loads a week has this machine washed a week on average and have you ever let it get smelly and or moldy ?

If it has done much more than 10 loads a week and or gotten fairly smelly and moldy it probably does not have that much more life in it.

In any case if you fix it either get the board rebuilt or buy a cheaper board, I would not spend $300 just for the part.

As a WP tech I have never seen a WP built DW go through 4 TFs in four years, are you sure the leads were replaced with the heaver leads when the first TF failed, if they are not replaced they will fail again and again.

John L. | ||

| Post# 1024337 , Reply# 4 2/11/2019 at 21:23 (1,992 days old) by IowaBear (Cedar Rapids, IA) | ||

| ||

| Post# 1024346 , Reply# 5 2/11/2019 at 23:09 (1,992 days old) by Joe_in_philly (Philadelphia, PA, USA) | ||

This thread has me wondering if blown electrical components are ever caused by dirty power or line surges. If so, that might explain why some people have more problems than others.

When I got my Kenmore HE3t and matching dryer (over 15 years ago), it was suggested that they be plugged into surge protectors, so I did. Is that necessary, or do appliances have built in power protection components? | ||

| Post# 1024410 , Reply# 9 2/12/2019 at 19:19 (1,991 days old) by Joe_in_philly (Philadelphia, PA, USA) | ||

| ||

| Post# 1024693 , Reply# 10 2/15/2019 at 11:45 (1,988 days old) by kb0nes (Burnsville, MN) | ||

Surges are often blamed, but not often the real cause of electronic failures. Certainly wasn't the reason the DW thermal fuses were failing.

A whole home surge protector isn't a bad idea, but lacking a nearby lightning strike you are very unlikely to have a true surge related failure.

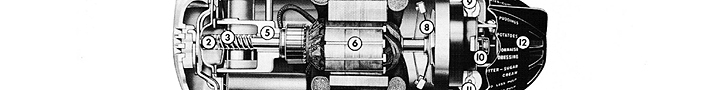

View Full Size

| ||

Post# 1024702 , Reply# 12 2/15/2019 at 14:48 (1,988 days old) by henene4  (Heidenheim a.d. Brenz (Germany)) (Heidenheim a.d. Brenz (Germany)) |

||

|

Polaritys reversed Hmm, yes, verry dramatic on AC, sure! | ||

Post# 1024727 , Reply# 13 2/15/2019 at 21:18 (1,988 days old) by Lorainfurniture  (Cleveland ) (Cleveland ) |

||

|

@henene4 Im not sure if you are kidding or not, but reverse polarity is a death sentence for a board. Specifically for the capacitors. | ||

Post# 1024730 , Reply# 14 2/15/2019 at 22:00 (1,988 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Appliance Board Failures Polarity is either reversed or not and there are a few appliance boards that do not function properly with reversed polarity, mostly spark ignition boards on gas ranges, BUT it does not hurt the board, you just have to correct the polarity and the range will work properly.

I have never seen any big increase in calls after lighting storms and we get some really serious lighting here in summer storms.

Brown outs are very uncommon and will not hurt boards.

All appliance boards have all the surge protection they need built in, A surge protector is most unlikely to ever help, if you have a serious surge they are not going to help. A large whole house would be far better than a cheap plug in protector.

70% of appliance board are caused by combinations of excess heat, moisture or other liquids seeping into areas they should not be in, cheap membrane touch controls, high current causing solder connections to fail, cheap capacitors and other components that are just not durable enough.

John L. | ||

| Post# 1025050 , Reply# 15 2/18/2019 at 19:21 (1,985 days old) by kb0nes (Burnsville, MN) | ||

| ||

Post# 1025056 , Reply# 16 2/18/2019 at 20:57 (1,985 days old) by Lorainfurniture  (Cleveland ) (Cleveland ) |

||

|

Next time you guys talk to anyone who knows anything about electronics, ask them what would happen if you install a capacitor backwards. Reverse polarity will kill a board , so will: low voltage, high voltage, dirty voltage, L to N, moisture, excess heat, ROACHES, and much more. | ||

Post# 1025072 , Reply# 18 2/18/2019 at 23:32 (1,985 days old) by Launderess  (Quiet Please, Thereīs a Lady on Stage) (Quiet Please, Thereīs a Lady on Stage) |

||

ROACHES | ||

Post# 1025999 , Reply# 23 3/1/2019 at 17:49 (1,974 days old) by chetlaham  (United States) (United States) |

||

|

I'm with Kb0nes and Combo52- reverse polarity will not harm anything, and 99.88% of the time the appliance can not tell the difference. About the only thing that I know of that can't take reverse polarity are some gas water heaters and furnaces- and its probably from what Combo mentioned.

In fact if you read Whirlpool's dryness sensor patents they specifically talk about designing the control so that it will still function with reverse polarity and without energizing the frame. Truth being gobs and gobs of appliances go into homes with reversed polarity, missing EGCs or both. Knob and tube, joe DIY hack jobs, non grounding outlets... its a given. And thank you Kb0nes for the van-diagram. Surges aren't as common as people think- especially regarding failed electronics. People are always calling their POCO after the lights dim (from a voltage dip) claiming surge damage to cover a device that had already failed was going to fail anyways. And FWIW the average home has so many MOVs from each circuit board having one that whole home surge protection is basically all ready in place. @Combo52: During storms my lights dim all the time from trees falling into lines- you are correct that absolutely no harm is done. And BTW- you are at orders of magnitude far greater risk (by occurrence)of an open neutral which electricians deal with all the time. Most surge protectors, even the best and glitziest ones will do absolutely nothing other then literally turning into a pile of melted flaming plastic. Yet you don't hear a peep about this from joe public or those making surge protectors. | ||

Post# 1026002 , Reply# 24 3/1/2019 at 18:07 (1,974 days old) by chetlaham  (United States) (United States) |

||

|

@bewitched- yup- and if you look at countries like the Philippines they run two hots to every socket and light fixture to get 230 volts as they use a center earthed supply like the US but simply don't have anything 120. Then you have older system in Norway which are 230 volts IT, meaning the supply transformer neutral is not earthed at all.

The only reason the NEC cares about polarity is from Edison base screw sockets- they don't want people being shocked while unscrewing a light bulb should they touch the metal base. UL testing requirements for small tools and appliances actually subjects them to reverse polarity and open ground- in order to pass they must not shock or dangerously malfunction. | ||

Post# 1026003 , Reply# 25 3/1/2019 at 18:13 (1,974 days old) by chetlaham  (United States) (United States) |

||

|

| ||

Post# 1026010 , Reply# 27 3/1/2019 at 20:15 (1,974 days old) by chetlaham  (United States) (United States) |

||

|

I hear you- but add just a hair of speed or at least try to and you pickup more MW, reduce just a bit (or try to) and you output less MW. But I hear you, in the end the rotor has to be in phase and turning without slip no matter what- which I assume thats what you mean?

"The entire time the turbine was spinning at 3600rpm, never changing speed. The torque demand is where the power is generated from and that was met by firing the boiler more. And since the boiler was in Boiler Follow mode and slaved to the turbine, if the turbine asked for more the boiler gave it. Adding excitation voltage increases the torque load of the flux lines the rotor has to cut through. Interesting enough the poles on a turbine generator are the rotor, and the stator windings are where the power is actually made. This is because the exciter windings are a lot less mass than the generator windings, and its something like the generator would be 4 times the size if that was the case. The logic for the turbine looked at its speed and the voltage output via the AVR for control and adjusted as necessary." Ok- I understand now. I want to say beautifully written- many thanks for the detail. I truly appreciate it. "If you lost a turbine on a generator trip it was pretty scary. The whole place comes to a grinding halt in a split second. The breaker opens, that sends a trip signal to the turbine throttle, which sends a trip signal to the burners. It all cascades back and if youre lucky enough you wont pop a safety valve and wake the neighbors. The junk Siemens turbine had a dump valve on the inlet header so that any full load rejection shouldnt lift a safety valve. When a steam generator is making 1.5 million pounds of steam an hour and all of the sudden it doesnt have a place to put said steam..." Question- does the steam dump to the exterior? Like one of those initial steam purges before starting electrical production for the first time? | ||

Post# 1026012 , Reply# 29 3/1/2019 at 21:00 (1,974 days old) by chetlaham  (United States) (United States) |

||

|

| ||

Post# 1026040 , Reply# 31 3/2/2019 at 06:27 (1,973 days old) by chetlaham  (United States) (United States) |

||

|

| ||

Comes to the Rescue!

Comes to the Rescue!