|

Thread Number: 79232

/ Tag: Modern Automatic Washers

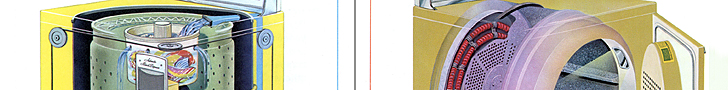

Why do frontloaders use so much less water? |

[Down to Last] |

|

Post# 1031587 , Reply# 2 5/2/2019 at 15:59 (1,912 days old) by henene4  (Heidenheim a.d. Brenz (Germany)) (Heidenheim a.d. Brenz (Germany)) |

||

|

Oh on the topic if they are any good. Course they are. Otherwise we wouldn't have been using them almost exclusively for the past 60 years over here... | ||

Post# 1031638 , Reply# 4 5/3/2019 at 00:28 (1,911 days old) by Launderess  (Quiet Please, There´s a Lady on Stage) (Quiet Please, There´s a Lady on Stage) |

||

Bringing this back on home...

Query was "Why do frontloaders use so much less water?"

Answer is compared to traditional top loading washing machines that submerge laundry in water, h-axis washing machines rely more upon the "beating saturated laundry against a rock" type of action. That is with h-axis washing machines only enough water is used to saturate the load (to various degrees), but not submerge. Laundry is then moved about in tub to be lifted and dropped against itself and sides of tub. This action works the concentrated water/detergent solution through textiles providing cleaning. Remember the laundry pie that covers all types of washing. Mechanical action Water (amount) Temperature Chemicals Time Any decrease in one means the others must increase to compensate. H-axis washing is far more gentle than the mechanical action of a central beater. As such cycles are longer to compensate. H-axis washers use less water than top loaders, so again ditto. There are two main ways of doing laundry. One either moves textiles through water, or moves water through textiles. Top loaders tend to do the former, while h-axis the latter. This is why top loaders run with far shorter cycles than h-axis. The more brutal central beater provides stronger mechanical action that forces laundry through a highly diluted wash water. Rinses can be one or maybe two because higher amount of water is used, and again product is diluted in all that water. Generally and borne out of decades of testing and use h-axis washers will produce cleaner and better results with less wear to textiles than top loaders with central beaters. All this using less water, energy and chemicals than top loaders. Commercial/industrial laundries never went with top loaders, but remained with h-axis machines. Laundromats are another story, but outside of North America there two h-axis washers dominate and have dominated. Proof of this is the vast and bewildering array of stain treatments, boosters and other laundry aids American housewives (or anyone else) doing laundry needs when top loaders dominated. This and the heavy use of chlorine bleach which hides a multitude of sins. | ||

Post# 1031647 , Reply# 6 5/3/2019 at 02:56 (1,911 days old) by DADoES  (TX, U.S. of A.) (TX, U.S. of A.) |

||

| ||

Post# 1031657 , Reply# 7 5/3/2019 at 05:15 (1,911 days old) by appnut  (TX) (TX) |

||

|

| ||

| Post# 1031658 , Reply# 8 5/3/2019 at 05:47 (1,911 days old) by Frigilux (The Minnesota Prairie) | ||

Longtime member of the front-load fan club here, as well, and for all the reasons listed above. As much as I’ve enjoyed the truly vintage top-load experience of a Speed Queen, I will undoubtedly make the switch back when the new SQ front-loaders appear at the local dealership.

In my experience they clean better, use substantially less water and energy, spin the load much drier, and use less detergent/bleach/etc. I certainly wouldn’t have employed front-loaders from 1986-2017 had they not done a sterling job. Having said that, the top-loader wins in ease of loading—and especially unloading—in the tight quarters of my apartment building’s laundry area. The open door of a modestly-sized SQ front-loader will literally come within a hair’s width of bumping into the neighbor’s Kitchen-Aid set, which resides opposite mine. | ||

| Post# 1031664 , Reply# 9 5/3/2019 at 07:29 (1,911 days old) by DE409 (Maryland) | ||

|

Thanks all! Very interesting stuff. | ||

Post# 1031702 , Reply# 10 5/3/2019 at 16:00 (1,911 days old) by Launderess  (Quiet Please, There´s a Lady on Stage) (Quiet Please, There´s a Lady on Stage) |

||

| ||

Post# 1031703 , Reply# 11 5/3/2019 at 16:06 (1,911 days old) by henene4  (Heidenheim a.d. Brenz (Germany)) (Heidenheim a.d. Brenz (Germany)) |

||

|

Highest usage cycle Ran my towel load today. Prewash, main wash, 4 rinses, each with full interim spins; 140F maintained for 40min in the main wash, full 1600rpm final spin, then dried. All in all not more then 42gal and 3kWh of usage, if even that. Even when translating that to US FLs, no way a TL could compete with that. | ||

Post# 1031705 , Reply# 12 5/3/2019 at 16:15 (1,911 days old) by MattL  (Flushing, MI) (Flushing, MI) |

||

|

I hope there was a decimal missing in the previous post.... | ||

Post# 1031708 , Reply# 14 5/3/2019 at 16:23 (1,911 days old) by Launderess  (Quiet Please, There´s a Lady on Stage) (Quiet Please, There´s a Lady on Stage) |

||

Sums things up nicely: www.home-water-works.org/...

As does this: www.greenbuildingadvisor.... Basically what one looks for (at least in USA) is water factor, that is amount of water required per pound of washing. The other measurement is modified energy factor which measures energy used for same. | ||

Post# 1031714 , Reply# 15 5/3/2019 at 16:58 (1,911 days old) by DADoES  (TX, U.S. of A.) (TX, U.S. of A.) |

||

| ||

Post# 1031725 , Reply# 16 5/3/2019 at 18:47 (1,911 days old) by kenwashesmonday  (Carlstadt, NJ) (Carlstadt, NJ) |

||

|

My 1972 Maytag A606 will wash a load of 8 bath towels, rinse them quite well, use 40 gallons of water total, and it's finished in less than 1/2 an hour.

There's more than a few ways to do your laundry well. | ||

Post# 1031732 , Reply# 17 5/3/2019 at 20:34 (1,911 days old) by geoff  (Cape Coral, FL) (Cape Coral, FL) |

||

sorry to be a waster

We have a 450 foot well that was guaranteed to never run out of water. We of course don't pay for water . I use thousands of gallons of water. We pay a flat sewer fee every 3 months. We were told by the town that if we metered our well, we would pay less for sewer taxes. No way are we doing that because I use so much water. I have a top loader that uses 27 gallons per full fill. I had considered a front loader because I do believe that they clean better. I chose a huge top loader because that is what I am used to. It cleans beautifully and I am very happy with it. To each their own I suppose.

| ||

Post# 1031758 , Reply# 18 5/4/2019 at 06:12 (1,910 days old) by mrboilwash  (Munich,Germany) (Munich,Germany) |

||

Frontloaders have not always been more water efficient than toploaders of a similar capacity, at least not in Europe.

The average water use of European FLs in the 1960s and 70s was about 180 liters which is more or less 50 gallons. Many of them did not spin at all between rinses even in a normal cotton cycle and if they did there was usually no way to keep them from sudslocking. Hence they still had to be waterhogs to ensure good rinsing. Their low energy use however made all the difference compared to a TLer. | ||

Post# 1031772 , Reply# 19 5/4/2019 at 10:08 (1,910 days old) by Launderess  (Quiet Please, There´s a Lady on Stage) (Quiet Please, There´s a Lady on Stage) |

||

Besides risk of sudslock

There has been considerable debate in at least commercial laundry community over extracting between rinses for h-axis washers. This has gone on largely ever since "washer-extractors" came upon the scene in 1950's.

One side feels that extracting wash between rinses forces dirty water through laundry which will act as a strainer. In their minds best to rinse via high dilution which is achieved not just with high water levels, but fact each successive rinse bath is in cleaner water. This of course means using relatively large amounts of fresh water. OTOH those who favor any sort of extraction (even if short pulse of low speed) feel it enhances rinsing and makes that process faster because less such cycles are needed on average. The older SQ washers at local laundryette didn't spin between any of the rinses IIRC. But then again maybe they did before the final rinse, cannot recall. The newer and more "energy efficient" SQ washers have short pulse spins between first rinses then a really good one before final. Obviously if you don't extract wash fully between rinses the load will absorb less water in subsequent cycle. This is one reason why not extracting between rinses means using more cycles. You basically are (again) counting on dilution to get most of soils, chemicals and whatever out of the wash. Interestingly on most modern domestic front loaders various "sensitive", "no crease", "easy cares/permanent press", etc... cycles do not extract between rinses. This and or maybe there is a gentle pulse or slow spin. Recommended recommended under loading (usually half of capacity)for some of these cycles increases the water to load ratio which should result in better rinsing. Tunnel washers that are rapidly coming to dominate commercial laundry industry do not extract between cycles; they cannot by design. Instead laundry is moved through progressively cleaner batches of water then finally extracted. | ||

| Post# 1031797 , Reply# 20 5/4/2019 at 15:54 (1,910 days old) by LowEfficiency (Iowa) | ||

>> First, most bearings favor only one direction of operation; top-loading machines require the bearing to

>> both resist forces side-to-side (from spinning or rotating) and up-and-down (to support the basket and/or >> agitator/impeller). No bearing is excellent for that -- roller bearings would not do well with supporting the >> weight, ball bearings wear out faster in this mode than in other modes, and the bearings that set rollers at >> a 45 degree angle, which in theory would help in this mode, are not very good at hight speeds for spinning. Is that really a problem though with proper bearing selection? For example, tapered roller bearings handle all kinds of continuous hard loads in service as automotive wheel bearings, including high side loads at speed. I'm not a subject matter expert, but a quick look at the SKF website shows all kinds of tapered roller bearings with extremely high speed ratings... such as the SKF 30202 which is rated for 17,000 RPM use with a do-not-exceed limit of 20,000 RPM. If our washing machine baskets could hold together at that speed, we wouldn't need dryers at all! :D | ||

| Post# 1031862 , Reply# 22 5/5/2019 at 10:33 (1,909 days old) by johnb300m (Chicago) | ||

|

I agree Paulo.

Front loaders get a bad rap for bearings not because of the inherent design of the front loader itself. But because the manufacturers use the very cheapest bearings and seals they can afford. And leave it up to the jaded engineers to sort it out with the pittance of a budget they’re given. | ||

Comes to the Rescue!

Comes to the Rescue!