|

Thread Number: 870

Restored 1958 PhilcoBendix Duomatic |

[Down to Last] |

Post# 52063 12/30/2004 at 21:43 (7,147 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Hi All: Just annoucing another Bendix Duomatic goes back to work! Thanks go to GregM for helping me lug 405 pound BerthaBendix back from Syracuse in October. Thanks go to John Eichinger for his help,advice,copies of Doctrine and several crucial parts without which Bertha would not be running right now! Thanks to MODERN! And Larry for sage advice! Very sage advice! It runs sooo much better than what I expected and sooo much better than my GE Combo. Bendix really got it right the first time! And they were the first from what the patents say. And YES JOHN LEFEVER it runs sooo much better than a Whirlpool Combo--especially my WP Combo!! Wait till you see the floppy wash, the gleaming chrome!!! It was a struggle everynite but I gave up house maintenance and snowblower maintenance and mailing Christmas cards to find myself in the basement after dinner and all weekend long. Below is a listing of what it takes to bring a "first floor machine" back to working order. Just think what it takes to bring a Farm Machine back to working order! Congratulations John Eichinger! She was tired! - A new Power Cord - A new tub pulley the old one was split in two -Thanks John E. -A new top panel as the old one blew off in the truck between here and Syracuse-Thanks to John E. -A 220V short to the cabinet, heater elements had to be removed and run hot at 110V to dry them out-Thanks to Larry! -Clean out a huge mouse nest and skeletons and did I mention the droppings througout the machine -Find 3 110V shorts due to mice chewing on odd parts of the wiring harness -After first water test found pump valve stuck closed had to be freed up carefully as the seal is 50 year old rubber -Repair leak around coin trap by descaling and installing a "new" coin trap - thanks to Larry! -Water valve had inoperative sections and after 3 days of not being there I found a very wet basement due to a very very slow leak. Calcium deposits all inside valve body were too blame -Rub down inside and outside of all boots with Glycerin to bring rubber back to healthy flexibility!!! -Spray outside of all boots with silicone- nicw tip from John E. -New drain hose which on a Bendix is an oddball size -Found dryer timer frozen , installed a Maytag dryer timer only to find out that it ran backwards! After much cleaning, working by hand and lubing I was able to get the original motor up and running again. Thank gawd for Lubit-8! -First wash the Cabinet filled up with water! Found that when moving the machine the tub had bumped the air gap on the fill line and so the line was spraying down the whole back of the cabinet! -First dry cycle the blower motor whipped its rubber cooling fan off and flung it across the basement in a fit! I replaced it with a solid aluminum fan blade from Grainger the is BOLTED to the motor shaft now. -Polish all chrome and enamel with Simichrome to get some bizarre crud off all the top surfaces. - The hardest thing to clean off was the "30 year old" Whisk which had been spilt and seeped down in between the top and cabinet. That stuff is like Super Glue! CLICK HERE TO GO TO Jetcone's LINK

| ||

|

| Post# 52065 , Reply# 1 12/30/2004 at 22:43 (7,147 days old) by rickr (.) | ||

Congrats! | ||

Post# 52067 , Reply# 2 12/30/2004 at 22:49 (7,147 days old) by Unimatic1140  (Minneapolis) (Minneapolis) |

||

| ||

Post# 52071 , Reply# 4 12/31/2004 at 00:24 (7,147 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

Atomic Proof! It's utterly different! | ||

Post# 52077 , Reply# 5 12/31/2004 at 01:16 (7,147 days old) by appnut  (TX) (TX) |

||

|

Jon, Congrats are way big time in order. I know pretty much the thumb-wheel controling/setting of the two timers and being typical bendix sequences. But, please tell me what the red, green, yellow and blue aircraft slide controls are for and what each of those settings are for each color. I believe John LF had one of these at the 2002 convention, but it hadn't been restored and I couldn't read all the markings anywhere ont he panel. Thanks. Bob

| ||

Post# 52080 , Reply# 6 12/31/2004 at 03:47 (7,147 days old) by foraloysius  (Leeuwarden, Friesland, the Netherlands) (Leeuwarden, Friesland, the Netherlands) |

||

| ||

| Post# 52082 , Reply# 7 12/31/2004 at 06:24 (7,147 days old) by bethann (Indianapolis) | ||

|

WOW! How BEAUTIFUL!!!!!!!!!!!!!!!!!!!!!!!!!! | ||

| Post# 52085 , Reply# 8 12/31/2004 at 08:34 (7,147 days old) by Brent-Aucoin () | ||

|

Thank Jon! Jon, You have really been working hard! It really paid off! Did you by chance take before and after photo's? It is beautiful! I bet you are having fun washing! Brent | ||

Post# 52087 , Reply# 9 12/31/2004 at 08:45 (7,147 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Thanks Louis here is the Club link for Bigger Pictures!

Bob Appnut I have put the picx on our club website so they will show larger and I will get you the button layout as well! Cheers Jetcone CLICK HERE TO GO TO Jetcone's LINK | ||

Post# 52088 , Reply# 10 12/31/2004 at 08:51 (7,147 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Thank you everyone

Yes the smell of Fresh Tranny Fluid now fills the basement- I think I heard Bertha Burp!! It is alot of fun to share and Robert & Terry are right; after all the hard work it is very enjoyable to sit back with a Vita Mix and let her tumble! Today's smoothie - Mango Chunks, Strawberries, Vanilla Yoghurt and Black Raspberry Juice YUMMM!!!! | ||

Post# 52089 , Reply# 11 12/31/2004 at 09:04 (7,147 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Button Sequence for Appnut

Hey Bob here is the control layout. The water valve has 4 solenoids on it! So there is a choice of many temperatures on the CE-788 model. Far left Red button is the soak cycle temperature switch. Choices are from the top: Cold-Cool-Warm Next button is Turquoise and is the Wash Temperature switch. Choices are from top: Warm-Medium-Hot On Hot the Magic Heater is engaged to keep the wash water hot all through the wash cycle. Next button is Yellow and is the water level selector. Choices from top are: Small-Medium-Full. A FULL load is "2/3 of the cylinder"! Next and farthest right button is Royal Blue and is the machine control switch. Choices are from the top: Reset (to reset an overloaded motor-yes that has happend already!) - On - Off. So you set all your cycle parameters and load the clothes and liquid Gain and close the door then you reach up and push the Royal Blue button up to ON and walk away! (NOT!) This machine was origianlly installed on 2/20/58! By Syracuse Automatic Service at 817 Butternut Phone:GR4-6061. jet | ||

| Post# 52091 , Reply# 12 12/31/2004 at 09:22 (7,147 days old) by jmirawm (Barling Arkansas) | ||

|

She is Beautiful Congrats on all your hard work Jon ! Many Happy washings with BERTHA ! | ||

| Post# 52096 , Reply# 13 12/31/2004 at 10:42 (7,147 days old) by geoffdelp (SAUK RAPIDS) | ||

|

Gorgeous Machine! Jon ... the loving care you took to restore this machine really shows! It is b-e-a-u-t-i-f-u-l!! Thanks for sharing your pics. | ||

Post# 52105 , Reply# 15 12/31/2004 at 12:36 (7,147 days old) by appnut  (TX) (TX) |

||

|

| ||

Post# 52107 , Reply# 16 12/31/2004 at 12:55 (7,147 days old) by peteski50  (New York) (New York) |

||

Restored 1958 PhilcoBendix Duomatic | ||

| Post# 52110 , Reply# 18 12/31/2004 at 13:27 (7,147 days old) by david (CA) | ||

|

Beautiful machine, Jon. One that is truly worthy of restoration. Congrats again-David | ||

| Post# 52144 , Reply# 19 12/31/2004 at 21:56 (7,146 days old) by kenmore1978 () | ||

|

combo comparisons I have the same question as parstcounterman, in what ways is the Duomatic "better than GE or KM/WP (or Easy or Maytag) combos? Maybe a column chart with each brands advantages/disadvantages compared to the others? | ||

Post# 52171 , Reply# 20 1/1/2005 at 04:57 (7,146 days old) by foraloysius  (Leeuwarden, Friesland, the Netherlands) (Leeuwarden, Friesland, the Netherlands) |

||

| ||

Post# 52205 , Reply# 22 1/1/2005 at 21:31 (7,145 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Best Combo

Hi all: Over the next few days I will try to illustrate why I think this machine is way ahead of the GE and WP combos. I have not used an Easy,Maytag,Norge,or Speed Queen machine or other combos except I saw Roberts "All Philco 1959" 29 inch Combo and from what he's said about its drying qualilty the 1958 machine is way ahead. But several members are familiar with the cycles of these other machines and armed with that I'll put a list together of what are to me the strong points of this machine and why that makes it better than the others. Thats the best I can do. You'll have to decide which machine you would buy in 1958. Fun time today Greg and your clothes looked soooo clean!!! Jet | ||

| Post# 52267 , Reply# 25 1/2/2005 at 17:12 (7,145 days old) by cadman (Cedar Falls, IA) | ||

| ||

| Post# 52311 , Reply# 26 1/3/2005 at 10:04 (7,144 days old) by ultramatic1 () | ||

|

AMAZING!!! I am duly impressed with your resteration. I am currently working on a late 50's Westinghouse portable dw and I will certainly ask you if I have any resto questions. | ||

Post# 52324 , Reply# 27 1/3/2005 at 14:26 (7,144 days old) by swestoyz  (Cedar Falls, IA) (Cedar Falls, IA) |

||

Fan Blade?

Hey John, I'm just curious. Where you stated that you got a replacement blade from Grainger, what Grainger item number did you use? I work @ Grainger and I'm really want to know how you got the item (Through the catalog, or through Grainger Parts) to possibly help out for parts avail through Grainger in the future. Ben | ||

Post# 52347 , Reply# 28 1/3/2005 at 19:27 (7,144 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Fan Blades

Hi Ben: You work at Grainger?? They have lots of parts! You just have to dig with dimensions! I went to the HVAC section and scrolled the pages till I came to "axial flow fan blades". From there all I needed was to pick the overall size "D". I did need to drill out the shaft hole as Graingers were too small. I also see that Paragon is still using the Mallory timer motor on their defrost monitors that motor if it is a CCW motor will work in Bendix,Westinghouse and I think Frigidaire appliances. I find if you look hard enough in Grainger you can find alot of things that will work. Axial flow fan blades are on pg 3619 in my catalog item 2C950. Cheers Jet PS I am putting together my list of reasons why this Combo rocks! | ||

| Post# 52374 , Reply# 30 1/4/2005 at 00:48 (7,143 days old) by kenmore1978 () | ||

|

Speed Queen Combo So Speed Queen made a combo? Didn't know that, anybody have one? | ||

Post# 52384 , Reply# 31 1/4/2005 at 04:21 (7,143 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

Wurlitzer Controls!!!

Hi Jon What a great machine and restoration, those controls are so like the Wurlitzer juke box combos`s... What spin speed is this 500/700rpm ??? or the diameter of the drum so we can use louis`s g force calc for final calibrations...LOL I take it the drier is a condensor with blower distribution fan, does it have extra heater elements above the water line or does it just use the water heating element for drier heat?? Cheers, Mike | ||

Post# 52399 , Reply# 32 1/4/2005 at 08:58 (7,143 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Hi Mike!

Nice to hear from you! Did you ever get my email about your 30 inch Bendix? I think us Yanks would have an easier time getting door boots from Bendix through your distributors over there! I think Bendix being one of the early worldwide manufacturer's reused their mouldings around the world! Can you still get boots for your 30 inch Bendix?? Let me know!!!!! Yes this machine is a condensor dryer with blower,which makes it unlike alot of other Yank Condensor dryers. The Drum diameter is 27 1/2 inches which makes it 69.85 cm. It has two spin speeds low at around 250 RPM and high is 505 RPM's. There are two sets of heating elements, the below waterline for wash and there is a heater box mounted at 11 o'clock looking from the front. The blower is placed at the junction of the vertical condensor tube and the horizontal heater box so the blower moves and turns the air stream 90 degrees. ( A patent for that exists). I'll scan some Doctrine for you to look at, it has good diagrams of the sacred Duomatic Cycle and theory. Check into those Boots for me!! Talk to you soon cheers jon | ||

Post# 52413 , Reply# 33 1/4/2005 at 14:33 (7,143 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

Bendix Boots To You To !!!

Hi Jon Sorry I didnt get your e-mail, it could be my spam killer is working overtime and deleted it if it was an unusual e-mail address,we are being plagued with spam over here... Can get the boots, they are generic, will get a couple in stock, I bet with all the new big bertha hetties I wonder if those door seals will fit as well??? The Lady I got my Giromatic from insisted that the Bendix washed & spun better than the new AEG they had replaced it with... The dryer sounds a very interesting concept, I wonder how much water it uses on the condensor.. Do you have a seperate spinner, I bet the drying time is minimal after putting the clothes through a spinner or unimatic and then completing the drying cycle. Cheers Mike

| ||

Post# 52419 , Reply# 34 1/4/2005 at 16:17 (7,143 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

| ||

Post# 52464 , Reply# 35 1/4/2005 at 21:57 (7,142 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Mike Thank You

I'll definetly take two and send two for Greg and I will send you a Yank cheque for the trouble! Those are boots are like gold over here! What are you doing next summer around August?? I am meeting my Ozzie cousin in Edinburgh for our 50th Bday, I'd love to stop on by for a day and nite and see you and your collection! How do I get my address to you for the boots? If your email is rejecting mine as spam let me know how to get the info to you. Cheers jon | ||

Post# 52990 , Reply# 36 1/10/2005 at 14:55 (7,137 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

Bendix Model G..My First Vintage Auto!!!!

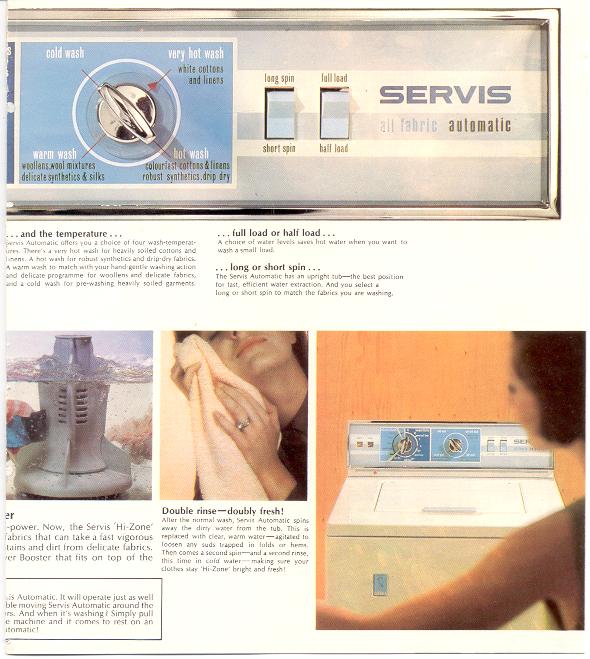

Hi Greg This model was produced over here in 1961, this was given to me a few months ago by a farmers wife who had kept it warm and cosy in their heated garage after changing it for a modern AEG because their repairman had retired and parts are difficult to find, as we all know.... Its in lovely condition, the porcelain looks like it just came out of the factory, it has a spin speed of 515rpm, when you think it only takes 9lb load for the size (and weight) of it, my mums first Servis auto measured 22.5 inches square and that took the same weight....LOL Will order the boots for you, might as well stock up while we can!!! CLICK HERE TO GO TO chestermikeuk's LINK

| ||

Post# 52991 , Reply# 37 1/10/2005 at 15:06 (7,137 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

Bendix Boots....& Holy Grail!!!

Hi Jon No problem with the boots, will search a few out and order them, e-mail me again and I will scan my system have managed to alter the spam settings , not so lethal but still effective... Have also managed to get a rubber boot for the 1961 slope front keymatic, all in its box etc... so there is still stuff out there, my mission this year is to find more of it... All I need to find is the Keymatic washer (and the Servis MK41 Holy Grail) to go with the boot....hopefully just in time for your August birthday bash etc...look forward to seeing you on terra firma UK... Cheers, Mike

| ||

| Post# 54253 , Reply# 38 1/22/2005 at 19:30 (7,125 days old) by Youngstown () | ||

|

1956 Duo I love your machine! I grew up with a 1956 Bendix; it lasted to the early 80's; my father was an elect. engineer and kept it running; it was a piece of work! It brings back great memories! We still talk about it like an old friend! | ||

Post# 55861 , Reply# 39 2/3/2005 at 14:16 (7,113 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Thank you Youngstown!!

Come out and see it run any time! Now that I have had it up and running for several weeks I am really taken with it! The condenser dryer never shrinks things just like my GE Combo even wool socks and shirts come out perfect with no shrinkage! But unlike the GE you can do a complete cycle wash to dry in 40 minutes! The GE comes in at 1.5 to 2 hours/cycle! And I don't know about everyone else but it cleans GREAT!! I have been using GAIN powder which has a good scent and using CHeer Liquid HE which really cleans the clothes! I know I told everyone I would list what about this machine makes it the best combo but I got sidetracked installing my Westy Streamliner so I'll post the listing soon. Cheers Jetcone | ||

| Post# 55869 , Reply# 40 2/3/2005 at 16:24 (7,113 days old) by cybrvanr () | ||

|

I love the look of the control panel on that washer! It looks more like a Jukebox than a washer's control panel! | ||

| Post# 56821 , Reply# 41 2/10/2005 at 21:41 (7,105 days old) by Mrcleanjeans (milwaukee wi) | ||

|

bendix BEAUTY Jetcone, that is the most gorgeous washer ever, and you did a great job restoring it. By the way, when did Philco-Bendix go out of the home appliance division,I know Philco alone went on for awhile. When was the last Philco-Bendix made?Wasnt it the early 60s?And what about Apex and Thor? | ||

| Post# 56829 , Reply# 42 2/10/2005 at 22:25 (7,105 days old) by Mrcleanjeans (milwaukee wi) | ||

|

p.s. is this your favorite washer? | ||

| Post# 57015 , Reply# 43 2/12/2005 at 05:01 (7,104 days old) by kenmore1978 () | ||

|

still waiting for the reasons you think this is the best combo | ||

Post# 59499 , Reply# 44 3/8/2005 at 22:02 (7,079 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Best Reasons

I like the Bendix Duomatic best as a Combination because: 1) It was the first ever Combination, that makes it a pioneer. 2) It uses a blow dryer for the heating cycle which speeds up the drying , it "blows" the door off my GE Combos! 3) It never goes above 155 degrees so there has been no shrinkage of my clothing , and condensor drying is very gentle compared with vented drying. 4) Using the soak and wash cycle gives 17 minutes of laundering at Different temperatures. Something I learned just recently that makes a power cleaning combination because different soiling responds to different temperatures. You'd think I'd know that one already!!!!! ADUH!!! 5) Bendix researched the whole wash cycle and concluded correctly that the tub to outer tub gap had to be no less than 20% of the inner tub diameter. This allows all the washing solution to be carried in and out of the drum by washing currents that develop between the inner and outer tubs. Any smaller gap and the currents don't form so there is no circulation--- REMEMBER Maytag had to install a pump system in the Neptune sumps to get all that concentrated detergent solution back up into the wash?? 6) Bendix discovered uneven baffles in the tub will break up tangleling when tumbling in one direction. My Combo never tangles! YAY! 7) Spinning at 505 RPM compared to GE's 225 really cuts the drying time down because the major amount of water is extracted after 275 RPM's. 8) Bendix worked out and patented the cause of "pasting" in Combination Washer-Dryers so that pasting is a thing of the past with Bendix higher spin speeds. My Kenmore goes through ridiculous gyrations for a long time before it settles into 525 RPM spin. Not necessary Bendix already worked it all out! 9) WAY COOL STYLING! 10) It is built like a Caddilac of the 50's and is as quiet as one! My GE's are great but they wail along! | ||

Post# 59505 , Reply# 45 3/9/2005 at 01:24 (7,079 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

20% of drum diameter? Wow... That's like 5.4" of a 27" drum. So the space between the inner basket and outer drum wall needs to be that TOTAL, 2.7" all the way around the drum or just at the lower portion where the water circulation is happening? "Pasting" is the clothes sticking to the drum after spin? To add another benefit of the Bendix, there is no need for a sump access plate or hatch inside the Bendix drum, the pump protector/filter is located under the drum and removed for easier cleaning through the access door on the front of the cabinet. Smooth, unobstructed drum surfaces lessen the possibility of rough edges and latches catching and snagging your delicate fabrics. | ||

Post# 59533 , Reply# 47 3/9/2005 at 08:42 (7,079 days old) by peteski50  (New York) (New York) |

||

Best Reasons  | ||

Post# 59551 , Reply# 48 3/9/2005 at 16:09 (7,079 days old) by gansky1  (Omaha, The Home of the TV Dinner!) (Omaha, The Home of the TV Dinner!) |

||

Condenser drying...

Many condenser dryers, especially early ones, did not use any blower to move the air through the drum. The Maytag, Hotpoint, Frigidaire among others used only the cool surface of the water on the side of the drum, or in the case of the Frigidaire, the cool surface of the aluminum Filtrator unit to attract and condense the warm moist air. They really are a wonderful way to dry clothes - towels especially come out incredibly soft and fluffy. I think maybe Jon was referring to the gentleness of the Bendix versus other condenser dryers that did not move air via a blower or fan, the cutoff temps for a non-blower condenser dryer were 180F + on the highest setting although most had temp controls that could be dialed down. Especially in the early days of condenser dryers, the man-made fibers and elastics weren't as common as they are in the typical washload today so the higher temps weren't as harmful. | ||

Post# 59595 , Reply# 50 3/9/2005 at 21:51 (7,078 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

Kenmore: The condensors that do not utilize blowers have the condensing surface somewhere inside the drum. As the drum turns it churns the moisture laden air across the condensor surface and moisture is removed. The heating process in a non blower machine is always done by broiling the clothes under radian tubes, as the clothes heat they release moisture into the drum air. Bendix had the patents for blow dry condensors which is why no one else made them in the 50's unless they paid royalties. As to clothes conditioning, in a condensor dryer the clothes never approach the dryness of a vented model for two reasons: 1) the use of cold water to condense never allows the interior air to become completely dry like room air. 2) the reuse of the sealed interior air and not the introduction of outside air prevents the clothes from coming into contact with bone dry air. Did you know that shrinkage in a dryer only occurs in the last ten minutes of a cycle IF the clothes are kept hot and allowed to reach a point of 0% moisture content? At that point they start shrinking and you can easily reach that degree of dryness in a vented model. When you remove your clothes from a condenser they have just the slightest tinge of moisture left in them, so slight that you feel it for a moment and as they hang it is gone. The best time to take your clothes out is right at the end because the residual heat will actually cause the clothes to steam slightly and if you hang or flatten them out they will drop all their wrinkles and self press. So you never really want to get your clothes BONE dry. Hope this clarifys Jet | ||

Post# 59622 , Reply# 52 3/10/2005 at 06:45 (7,078 days old) by chestermikeuk  (Rainhill *Home of the RailwayTrials* Merseyside,UK) (Rainhill *Home of the RailwayTrials* Merseyside,UK) |

||

European Condensor Dryers....No Blowers....

In the seventies a lot of the combined washer dryers where condensor dryers but didnt have a blower to distribute a stream of warm air... Manufactures such as Frigidaire and Miele offered top loading slimline automatics, others such as Ariston, Newpol, Eastham & Fagor offered standard front loaders, most had low spin speeds of 460 although the Miele had a faster spin the tumble dryer took over 2 hours to dry half the washload. They simply used the water heater situated under the drum, this used to cycle on and off linked to a thermostat at the top of the outer drum.The cold water would trickle slowly through the drum intermittently and the steam would condense and be pumped out from the wash drain. Bendix always offered the warm air blower machines with seperate warm air blowers, these machines really took off over here in the 80`s when Hoover & Hotpoint offered fast spin autos (1,000rpm) with a blower tumble dryer etc . Very interesting how they work (well to us anyway!!!) the earlier full size condensor dryers used a lot more electricity due due the time the condensor took to dry the loads, I remember being in a test centre and using one of these dryers.....with a full load of towels spun at 1200rpm placed on a high heat setting, after 20 mins the clothes where steaming hot, we took them all out and shook them, steam all over the place but they dryed almost immediatly, whereas if the dryer had continued it would have taken over an hour extra to fully dry... I think more work needs to be done on condensor dryers, very interested in the heat pump method form AEG...my old Servis 9lb vented dryer work on a low heat of 1.9kw and a high airflow....this world dry a full load of towels spun at 850rpm in 45 mins and very economical to use... | ||

Post# 59698 , Reply# 53 3/10/2005 at 21:29 (7,077 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

AEG vs LG

Mike, what does the Heat Pump do in the AEG? Does it try to recover heat in the condensed water stream and put it back into circulation in the drum?? I am really wondering about the LG drying times because it spins at 1400 I think and has a blower, in fact it is configures identical to the Bendix of 50 years ago! Peteski, Jeff want to weigh in here on drying times?? Jon | ||

Post# 59733 , Reply# 54 3/11/2005 at 06:55 (7,077 days old) by peteski50  (New York) (New York) |

||

AEG vs LG  | ||

Post# 59897 , Reply# 55 3/13/2005 at 21:37 (7,074 days old) by Jetcone  (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) (Schenectady-Home of Calrods,Monitor Tops,Toroid Transformers) |

||

| ||

Comes to the Rescue!

Comes to the Rescue!