|

Thread Number: 89634

/ Tag: Modern Automatic Washers

Why don't VMW have a break? |

[Down to Last] |

Post# 1142270 2/15/2022 at 15:13 (892 days old) by chetlaham  (United States) (United States) |

||

|

The VMW washer is essentially Whirlpool's portable from the 90s, just adapted to a larger tub, basket and agi. These portables had a break band which relaxed when the splutch was engaged by a simple solenoid wired in parallel with the drain pump.

Why did Whrilpool do away with the brake band? The old design was simpler and no need for a lid lock. | ||

|

| Post# 1142282 , Reply# 1 2/15/2022 at 17:16 (892 days old) by Maytag85 (Sean A806) | ||

| ||

Post# 1142284 , Reply# 2 2/15/2022 at 17:54 (892 days old) by chetlaham  (United States) (United States) |

||

|

| ||

Post# 1142287 , Reply# 3 2/15/2022 at 18:01 (892 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

why no brake | ||

Post# 1142288 , Reply# 4 2/15/2022 at 18:05 (892 days old) by chetlaham  (United States) (United States) |

||

|

| ||

Post# 1142315 , Reply# 5 2/15/2022 at 21:16 (891 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Washer Reliability Something is always more reliable when you eliminate something that can break, through history every AW ever built with a tub brake sometimes had problems with them that cost time and money to fix and it was seldom cheap or easy to fix or replace the brake, a lid lock is a lot easier and cheaper to replace.

I am glad you are not designing appliances.

John L. | ||

Post# 1142323 , Reply# 6 2/15/2022 at 22:16 (891 days old) by chetlaham  (United States) (United States) |

||

|

The longevity/dependability or VMW vs DDs speaks that the lid lock and motorized shifter is a step back, especially in commercial settings where short comings are magnified.

You view everything from the lens of repair which I understand as that is what you do day to day, however, you have to consider the user perspective that most people would rather have a tub brake fail after 15 years than have multiple failures in the first 5 years of service. Like it or not, one day I do intend to design appliances. There needs to be a revolution in the industry. | ||

Post# 1142329 , Reply# 7 2/16/2022 at 00:23 (891 days old) by tolivac  (greenville nc) (greenville nc) |

||

|

VMW more reliable????How come I see so many of them at the trash transfer dump site I use.See many in the appliance dumpsters.At least with the DD-you could replace the coupler-the BD-the belt.With VMW?And on a trash truck RL New Way RL watched a VMW machine get crushed!!LOVED IT!!! | ||

| Post# 1142330 , Reply# 8 2/16/2022 at 02:01 (891 days old) by Maytag85 (Sean A806) | ||

Reply #5

I donít buy into on when you eliminate something such as the transmission or tub brake it makes it more reliable, in fact it makes it more unreliable and noisy since the computer crap has to reverse the motor to stop and reverses it back and forth which is more obnoxious than my Ď63 Whirlpool is in operation. ďTechnologyĒ crap doesnít solve anything, it just makes it worse and thatís why washing machines and anything modern since the previous generations before me fall for all the ďtechnologyĒ crap which is nothing more than a gimmick and is just marketing. You can only push technology and engineering so far before you end up with something just falls apart since there was little to no research and development behind it and that is why bugs arenít often worked out before that particular item is released onto the market. I may be 22 (going on 23 next month) and NEVER allow myself to fall for anything modern and fancy since Iíve had friends and family fall for the latest and greatest and start kvetching when it doesnít work or has broke since it was cheaply made and most of the time ďI told you soĒ.

| ||

Post# 1142339 , Reply# 9 2/16/2022 at 04:27 (891 days old) by henene4  (Heidenheim a.d. Brenz (Germany)) (Heidenheim a.d. Brenz (Germany)) |

||

|

*rolls eyes* You can get a VMW for 300$ today. That's 180$ in 2000. Or 90$ in 1980. Or 30$ in 1960. In reverse, a WP washer in 1960 was 300$. That's 800$ in 1980. Or 1800$ in 2000. Or 2800$ today. Go pay that amount for a washer and in home use, you will still get 50+ years of service out of it. The VMW is made cheaply yes - because it is. | ||

Post# 1142341 , Reply# 10 2/16/2022 at 04:54 (891 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Reliability of VMW whirlpool built washers

I never said that the overall reliability or longevity of these machines was better than direct drive machines.

But they are more reliable than they could be if they had had a brake like the earlier versions of these machines that came from Mexico they were often problems with the brake on those machines. If you look at consumer reports durability surveys it seems that there are no more problems with top load washers like these today than there were 20 years ago. Yes it is true many people choose not to spend two to $400 on a machine that only cost three to $500 I donít blame them there are thousands of these machines being thrown away every day. Guess what the most replaced part on a direct drive washer was in the first five years you guys might be surprised hint it was not to drive coupler. Henriks analysis of cost of washing machines and the repair ability of them is very good in post number nine. Chet, Sean and others of you guys that want to become appliance engineers should be very careful about what you write on sites like this as your future employers will find this information and youíll be disqualified pretty quickly for the inflammatory things that donít make any sense that youíre writing. There of been a couple other young guys who participated on this site who have gone on to have jobs in the industry but they didnít write the scope of nonsense constantly. John L | ||

| Post# 1142358 , Reply# 11 2/16/2022 at 10:52 (891 days old) by Maytag85 (Sean A806) | ||

If employers are snooping around on the internet for their employees, thatís a complete violation of privacy. I actually am going to start a vacuum cleaner repair business this spring since I donít feel like being micromanaged by management/bosses, and want to do something I enjoy doing such as working on appliances.

| ||

Post# 1142363 , Reply# 12 2/16/2022 at 12:17 (891 days old) by appnut  (TX) (TX) |

||

|

| ||

| Post# 1142366 , Reply# 13 2/16/2022 at 13:29 (891 days old) by Maytag85 (Sean A806) | ||

Reply #12

Thanks! I have had a interest in vacuums for some time but has been a hiatus since in 2015 is when I basically started collecting washers but have always had a interest in vacuums for some time. I fixed a few vacuums for a family friend back in 2013 and was something I enjoyed since it pertains to my interest in appliances.

| ||

| Post# 1142369 , Reply# 14 2/16/2022 at 14:01 (891 days old) by vacerator (Macomb, Michigan) | ||

|

A brake also isn't necessary with a lid lock. | ||

Post# 1142417 , Reply# 15 2/17/2022 at 17:47 (890 days old) by chetlaham  (United States) (United States) |

||

|

Mexican VMWs

No one is making any inflammatory remarks, just people expressing their informed point of view as you are expressing yours. We both know this.

The brake band and solenoid approach (one failure point {continuous duty solenoids rarely fail}) in the long term is still more reliable than having a lid lock, the shifter position input, optical sensor, motorized actuator and control board logic to tie it all together (6 failure probabilities). Approximately 2 out of ever 100 Whirlpool washers are lemons, no doubt about it. A certain percentage of washers will always have brake failures in the first 5 years just as they will have lid lock/control/actuator failures. I do not dispute that. However, in the long term 10-15 years far more user will experience issues with the hexa combo than a brake band failure. Mexican VMWs are much more simple. In wash mode contact 4B is closed whereby a simple triac board will cycle power between each leg of the motor to achieve agitation. In drain 4T closes, energizing both the drain pump and clutch/brake solenoid. After the pump out elapses, 8B closes sending the motor directly into spin. If the lid is opened, all 3 parts (motor, solenoid, pump de-energize) causing the brake band to engage squeezing the splutch drum. Close the lid all the energize and accelerate the tub. At the end of the cycle 8B opens with 4T following several seconds latter causing the tub to brake and come to a quick stop. Worse that happens is the brake band does not disengage or becomes tangled along the brake drum causing the motor to hum until its thermal protector opens. Wet clothes mean repair. Or the brake does not engage, tub just comes to a stop on its own. In the US version, the control board has to make sure the lid is closed, pulse the lid lock motor correctly until the lock switch is satisfied, then pulse the shifter motor correctly without over or under travel, have the correct shifter position input, pulse the motor a bit to get the splutch teeth in, ramp to spin as the control is looking for exactly the correct speed inputs whole time, spin to speed, drop the motor, then wait for the optical sensor to read the targeted speed required to begin the whole process in reverse of unlocking the lid and disengaging the splutch. Any discrepancies trigger a failure code, or don't unlock the lid at the end leaving users with a washer that won't open (it does happen). The whole complex of logic and applied feedback is unnecessarily complex, and given the cheap parts that loose tolerance, thats a given and in part why VMWs are filling up the scrap yards in 5 years. Great for Whirlpool, not the user. Mexican customers do not have that worry 98 out of 100 times. | ||

Post# 1142422 , Reply# 16 2/17/2022 at 18:01 (890 days old) by chetlaham  (United States) (United States) |

||

|

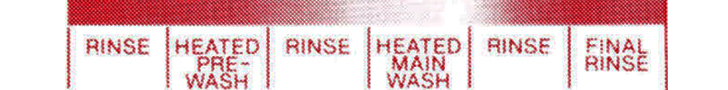

Braking without a brake

@Vacerator: Now you're eyes are open! GE Harmony washers had a braking power resistor which essentially turned the motor into a generator, the tub's energy dissipated as heat in the resistor. The other way is to apply a weak DC current to the motor which brings the rotor to a quick stop.

Both methods work great, Where GE users enjoy no lid lock or premature failures/reliability issues.

View Full Size

| ||

| Post# 1142433 , Reply# 17 2/17/2022 at 18:30 (890 days old) by vacerator (Macomb, Michigan) | ||

|

That's called dyanmic resonance or regenerative braking. Ity also generates heat. Diesel Locomotives have been using it since the early 1950's. | ||

Post# 1142441 , Reply# 18 2/17/2022 at 19:33 (890 days old) by combo52  (50 Year Repair Tech Beltsville,Md) (50 Year Repair Tech Beltsville,Md) |

||

Reply number 15

Chat you really need to get out in the real world, the Mexican world washers that were sold here over the last 25 years seldom lasted more than about five years they were far worse than the VMW machines the bearings failed in those which such frequency it was ridiculous, and they were even less repairable.

You can lecture me with all the theory you want but you donít have the practical experience to know whatís really happening in the field there will be many VMW washers that go to 20 or 25 years without a single repair. John L | ||

Post# 1142443 , Reply# 19 2/17/2022 at 19:57 (890 days old) by chetlaham  (United States) (United States) |

||

|

Just improve the bearings. When Alliance improved the original Amana design it went from 5 to 15-20 years in service on average.

Imagine the current US VMW with the same tub seal and bearings, but with a brake band, spring and solenoid. {Better yet, I would have removed the gears from the transmission, used a smaller impellar and let an EM timer reverse the motor ever 30-60 seconds, maybe even 10 seconds} If users had the option they would chose no lid lock, error codes, or extra time in actuating and coasting down. I have no doubt there will be VMW going after 15 years, but in that same span of time a sizeable chunk of VMWs will have been tossed or repaired. I don't deny your repair experience, but you forget that the rest of us are seeing scrapped VMWs and repair threads about lid lock, drive and control problems. | ||

Post# 1142444 , Reply# 20 2/17/2022 at 20:09 (890 days old) by DADoES  (TX,†U.S. of A.) (TX,†U.S. of A.) |

||

| ||

Post# 1142450 , Reply# 21 2/17/2022 at 20:36 (889 days old) by luxflairguy  (Wilmington NC) (Wilmington NC) |

||

|

Especially when one person won't give them a break! Old and tiring... | ||

Post# 1142454 , Reply# 22 2/17/2022 at 20:50 (889 days old) by chetlaham  (United States) (United States) |

||

|

| ||

Comes to the Rescue!

Comes to the Rescue!